Heeger Metal – Premier Supplier of Refractory Metals and Custom Alloys

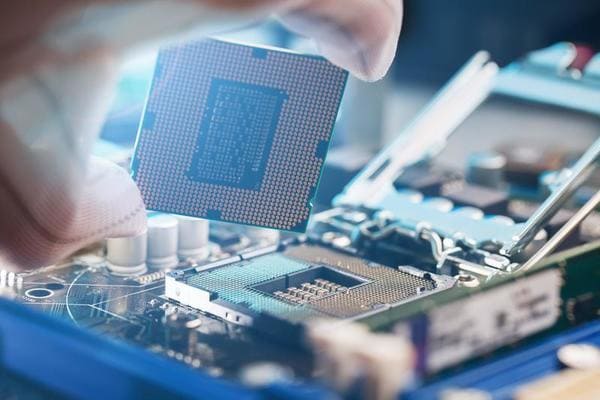

Heeger Metal specializes in providing high-performance refractory metals, rare earth metals, and custom alloys, delivering precision-engineered products to meet the demanding needs of industries worldwide. With advanced machining capabilities, we produce high-precision tungsten, molybdenum, niobium, and other refractory metal products in various forms, including rods, tubes, plates, wires, and foils. Whether for aerospace, electronics, or energy applications, our materials offer exceptional high-temperature strength, reliability, and performance.

HM Owns A Cutting-Edge Precision Machining Center

HM has an advanced production center with the latest equipment, offering high-precision, efficient manufacturing services to ensure product quality meets international standards and customer needs.

The processing services we offer include:

- CNC Precision Machining

- Laser Cutting

- Water Jet Cutting

- Welding and Assembly

- Surface Treatment

- Mold Processing

- Parts Machining

Most Popular Shapes and Forms

Besides the Most Popular Shapes and Forms Below, We Offer a Wide Variety of Products to Meet Your Needs.

Powder

Plate / Sheet

Rod/Bar

Tube/Pipe

Wire

Foil/Strip

Target

Crucible

Mesh

Foam

Ingot

Customized

Refractory Metal & Alloys Applications

10+

Years of experience

HM has over 10 years of experience and is a leading global supplier of refractory metals and alloys. We specialize in high-quality tungsten, molybdenum, tantalum, rhenium, and more, offering a wide range of product forms and reliable customized solutions for specific applications to clients worldwide.

Why Clients Chose us

Our clients include leading research institutions, universities, and R&D departments of various enterprises. They trust us for our expertise in providing high-quality, tailored solutions in metals and alloys, ensuring precision and reliability in every project.

Sonya Martin

Norcross, GA

“Heeger Metal delivers great custom alloys tailored to our needs, ensuring precise solutions for our applications.”

James Anderson

Southfield, MI

“Heeger Metal offers excellent value with high-quality materials, fast delivery, and competitive pricing.”

Johnny Schade

Martinsburg, WV

“We’re always impressed by Heeger Metal’s fast turnaround, meeting tight deadlines without delays.”

our partners

We appreciate our partners’ support and trust and look forward to working together to achieve greater success.

LATEST ARTICLES & BLOGS

Uses of High-Density Tungsten Sheets in Aerospace Applications

Why Thickness Affects the Density of Tungsten Sheets

High-Density Tungsten Sheet for Semiconductor Industry

contact us

We will get back in 24 hours.

We offer free quotes and technical services to ensure you get the best solutions. Looking forward to hearing from you!

call now

925-385-8104

Email now

max@heegermaterials.com