Poudre de molybdène

Poudre de molybdène

Pureté : 99,95%-99,99%

Matériau : Mo pur361, MoTZM (Mo364), Mo-Lanthanoxid (ML)

La poudre de molybdène est fabriquée à partir de molybdène de haute pureté, présentant une surface élevée et une large gamme de distribution de la taille des particules. Elle est très polyvalente dans les domaines de la métallurgie et de la science des matériaux. En tant que principal fournisseur et fabricant de produits de molybdène de qualité supérieure, Heeger Materials s'appuie sur une technologie de pointe pour fournir des poudres de molybdène et d'alliages de molybdène de grande pureté pour une large gamme d'applications.

Ou envoyez-nous un courriel à l'adresse suivante max@heegermaterials.com.Fiche technique de la poudre de molybdène

| Référence : | HMMO1086 |

| Matériau : | Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML) |

| La pureté : | 99.95%-99.99% |

| Forme : | Irrégulier ou sphérique |

| Taille des particules : | FSSS 1-10 μm, 0-25 μm, 15-53 μm, 53-105 μm, 53-150 μm, ou tamis selon les besoins. |

Poudre de molybdène

Molybdène est un métal gris argenté dont le point de fusion est de 2623 ℃ et la densité de 10,2 g/cm.3. C'est l'un des métaux disponibles dans le commerce dont le coefficient de dilatation thermique est le plus faible. Poudre de molybdène est généralement produit en réduisant le paramolybdate d'ammonium ou le MoO3 calciné avec de l'hydrogène. La teneur en oxygène peut être réduite à des niveaux inférieurs grâce à des conditions de réduction spécifiques. HM peut fournir de la poudre de molybdène irrégulière et sphérique de haute qualité avec des tailles de particules allant de grossières à ultrafines.

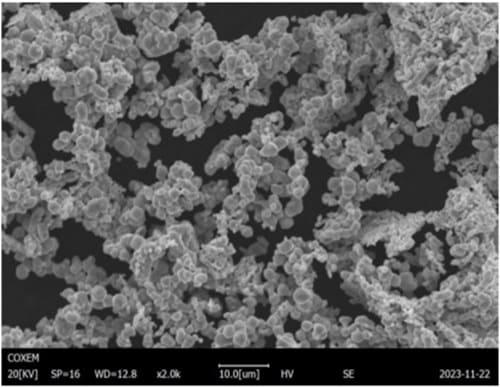

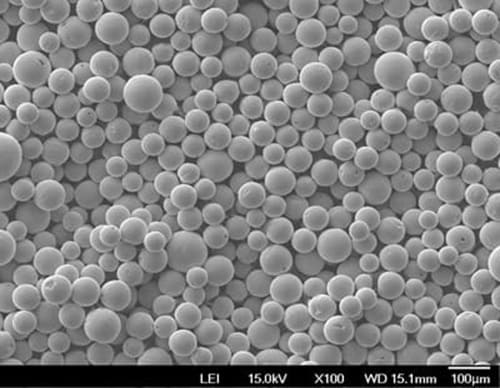

Poudre de molybdène Poudre de molybdène irrégulière SEM Poudre sphérique de molybdène SEM

Spécifications de la poudre de molybdène

| Produit | HM-Mo-1 | HM-Mo-2 | HM-Mo-3 | |

| Teneur en Mo (%) | ≥99.95 | ≥99.90 | ≥99.80 | |

| Teneur en impuretés (≤%) | Cd | 0.001 | — | 0.001 |

| Fe | 0.005 | 0.006 | 0.030 | |

| Al | 0.0015 | 0.002 | 0.005 | |

| Bi | 0.0010 | — | 0.001 | |

| C | 0.0060 | 0.010 | 0.020 | |

| Ca | 0.0020 | 0.002 | 0.004 | |

| Sb | 0.0010 | — | 0.001 | |

| Cr | 0.0030 | — | — | |

| Cu | 0.0010 | 0.001 | — | |

| Mg | 0.0020 | 0.003 | 0.005 | |

| Mn | 0.0005 | — | — | |

| Ni | 0.0010 | 0.003 | 0.005 | |

| O | 0.1500 | 0.25 | 0.25 | |

| P | 0.0010 | 0.001 | 0.005 | |

| Pb | 0.0010 | — | 0.001 | |

| Sn | 0.0010 | — | 0.001 | |

| Si | 0.0020 | 0.003 | 0.010 | |

| Ti | 0.0010 | — | — | |

| W | 0.0150 | — | — | |

Poudre de molybdène Caractéristiques

- Résistance à haute température et résistance au fluage

- Excellente résistance à la corrosion

- Bonne conductivité thermique et électrique

- Faible coefficient de dilatation thermique

- Dureté élevée et résistance à l'usure

- Bon pouvoir lubrifiant dans l'atmosphère de vulcanisation

- Disponible en différentes distributions de tailles de particules

Méthode de production de la poudre de molybdène

Poudre de molybdène peuvent être produites par différentes méthodes, la réduction par l'hydrogène étant le procédé industriel le plus couramment utilisé. Cette méthode permet un contrôle précis de la morphologie, de la taille des particules et de la pureté de la poudre.

- Réduction de l'hydrogène: Réduction du trioxyde de molybdène avec de l'hydrogène pour produire de la poudre de molybdène.

- Décomposition thermique: Chauffage de composés de molybdène tels que le molybdate d'ammonium pour former de l'oxyde de molybdène, suivi d'une réduction par l'hydrogène.

- Production électrolytique: Les précipités de poudre de molybdène sont produits par précipitation électrolytique aqueuse à partir d'une solution acide de molybdate.

- Réduction thermique du calcium: Réduction du trioxyde de molybdène à l'aide de calcium.

Applications de la poudre de molybdène

- Métallurgie des poudres: La poudre de molybdène est une matière première importante pour la production d'alliages de molybdène et de produits à base de molybdène. Elle est largement utilisée pour la fabrication d'alliages à haute résistance, à haute température et résistants à la corrosion.

- Industrie électronique: La poudre de molybdène est également utilisée pour fabriquer des composants électroniques tels que des électrodes, des dispositifs semi-conducteurs et des fils d'électrode pour les machines d'électroérosion.

- Industrie chimique: La poudre de molybdène est utilisée comme catalyseur et matériau résistant à la corrosion dans les industries chimiques et pétrolières.

- Aérospatiale: La poudre de molybdène est utilisée pour fabriquer des composants à haute température tels que les aubes des turbines à gaz et les aubes directrices des moteurs à réaction.

- Industrie du verre et de la céramique: La poudre de molybdène est également utilisée pour fabriquer des éléments chauffants pour les fours à haute température et des électrodes pour les fours de fusion du verre.

Emballage de la poudre de molybdène

La poudre de molybdène est soigneusement placée dans des caisses en bois ou des cartons avec un support supplémentaire en matériaux souples pour éviter tout déplacement pendant le transport. Cette méthode d'emballage garantit l'intégrité des produits tout au long du processus de livraison.

Propriétés du molybdène

Télécharger

Obtenir un devis

Nous vérifierons et vous contacterons dans les 24 heures.

Autres produits en poudre

Heeger Metal propose une gamme complète de poudres métalliques, y compris des poudres sphériques et des nanopoudres. Nos poudres métalliques de haute qualité sont idéales pour les applications d'impression 3D, de métallurgie des poudres, d'électronique et de fabrication avancée. Ces poudres offrent une consistance, une fluidité et une distribution granulométrique excellentes, garantissant des performances supérieures dans divers processus industriels. Que vous ayez besoin de poudres métalliques personnalisées ou de poudres d'alliage standard, nos produits répondent aux normes de qualité les plus élevées en matière de précision et de fiabilité.

Autres produits à base de molybdène

Nous proposons une large gamme de produits à base de molybdène et d'alliages de molybdène, des poudres aux pièces finies, avec des options de personnalisation disponibles. Veuillez consulter la liste de nos produits les plus courants.