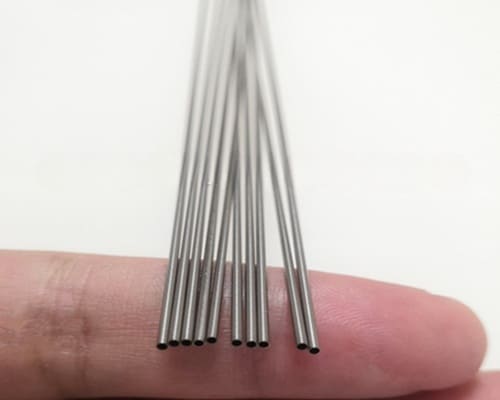

Tube en nitinol

Tube en nitinol

Matériau : NiTi, NiTiFe, NiTiCu, NiTiCo, NiTiCuCr, NiTiNb, etc.

Norme : ASTM F2063-12

Le tube en nitinol est fabriqué à partir de nickel et de titane dans un rapport proche de 1:1. Il possède un effet de mémoire de forme unique et une superélasticité, largement utilisés dans les appareils médicaux, l'aérospatiale, la robotique et l'électronique grand public. Le tube capillaire est également notre produit phare. En tant que fournisseur et fabricant de premier plan de produits en alliages de nitinol de première qualité, Heeger Metal s'appuie sur une technologie de pointe pour fournir des tubes en nitinol de haute qualité pour diverses applications.

Ou envoyez-nous un courriel à l'adresse suivante sales@heegermaterials.com.Fiche technique du tube en nitinol

| Matériau : | NiTi, NiTiFe, NiTiCu, NiTiCo, NiTiCuCr, NiTiNb, etc. |

| Catégorie : | Superélastique et mémoire de forme |

| Standard : | ASTM F2063-12 |

| Diamètre : | ≥0,25 mm, ou sur mesure |

| Forme disponible : | Tige, barre, barre rectangulaire, tige filetée, ou sur mesure |

| Surface : | Noir, décapé ou poli |

| Af Température : | -10 ℃ à 120 ℃ |

Qu'est-ce que l'alliage de nitinol ?

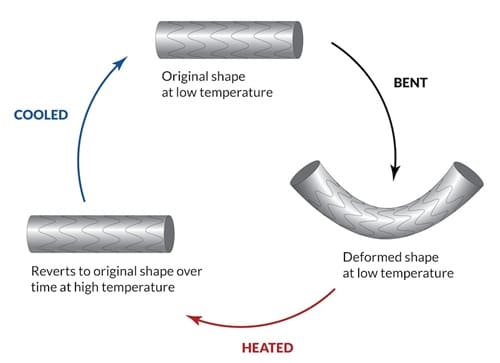

Le nitinol, également appelé alliage à mémoire de forme NiTi, est un alliage métallique composé de nickel et de titane, généralement dans un rapport proche de 1:1. Il possède un effet de mémoire de forme unique et une superélasticité qui lui permettent de reprendre une forme prédéfinie lorsqu'il est chauffé ou de retrouver sa forme d'origine après une déformation importante. Il offre un taux d'expansion supérieur à 20%, une résistance à la fatigue de 107 des propriétés d'amortissement dix fois supérieures à celles des ressorts ordinaires et une résistance à la corrosion supérieure à celle de l'acier inoxydable. En raison de son excellente biocompatibilité, de sa résistance à la corrosion et de ses propriétés mécaniques, l'alliage de nitinol est largement utilisé dans les dispositifs médicaux (par exemple, les stents et les fils orthodontiques), l'aérospatiale, la fabrication industrielle et les produits de consommation.

Tube en nitinol

Le tube en nitinol est connu pour son effet unique de mémoire de forme et sa superélasticité. À température ambiante, le tube en nitinol peut subir une déformation importante et retrouver entièrement sa forme d'origine, tandis que le fait de le chauffer à une température spécifique déclenche sa capacité à "se souvenir" et à revenir à une forme prédéfinie. Le nitinol présente également une excellente biocompatibilité, une résistance à la corrosion et une grande résistance à la fatigue, ce qui lui vaut d'être largement utilisé dans les secteurs de la médecine, de l'aérospatiale, de l'automobile, de l'électronique et de l'énergie. Sa grande capacité d'amortissement et sa sensibilité à la température augmentent encore son potentiel dans l'amortissement des vibrations, le contrôle de la température et les structures intelligentes. HM peut proposer des solutions personnalisées pour le diamètre et l'état de surface en fonction d'exigences spécifiques.

Tube en nitinol Tube capillaire en nitinol

Propriétés mécaniques des tubes en nitinol : Grades superélastiques

| Travail à froid | Superélastique | |||||||

| Grade | Lingot As(℃) | Min. Uts(psi) | Élongation(%) | Min. Uts(psi) | Élongation(%) | Plateau de chargement(ksi) | Plateau de déchargement(ksi) | Actif Af (℃) |

| Nitinol #1 | De -35 à -10 | 220,000 | >4 | 180,000 | >10 | >70,000 | >20,000 | +10 à +18 |

| Nitinol #2 | De -45 à -15 | 250,000 | >4 | 210,000 | >10 | >80,000 | >35,000 | 0 à +18 |

| Nitinol #4 | De -10 à +10 | 220,000 | >4 | 180,000 | >10 | >65,000 | >7,000 | +14 à +22 |

| Nitinol #9 | ≥ +35 | 220,000 | >4 | 160,000 | >10 | >75,000 | >25,000 | ≤0 |

Tube en nitinol Propriétés mécaniques : La mémoire des formes

| Travail à froid | Mémoire de forme | |||||||

| Grade | Lingot As(℃) | Min. Uts(psi) | Élongation(%) | Min. Uts(psi) | Élongation(%) | Plateau de chargement(ksi) | Plateau de déchargement(ksi) | Actif Af (℃) |

| Nitinol #5 | ≥ +85 | 220,000 | >3 | 160,000 | >10 | N/A | N/A | ≥ +85 |

| Nitinol #6 | +35 à +85 | 220,000 | >3 | 160,000 | >10 | N/A | N/A | +40 à +80 |

| Nitinol #8 | +10 à +35 | 220,000 | >3 | 160,000 | >10 | N/A | N/A | +22 à +40 |

Composition chimique du matériau du tube en nitinol

| Composition chimique (wt%) | ||||

| Fe | Ni | Cr | Cu | Nb |

| ≤0.05 | 54.5-57.0 | ≤0.01 | ≤0.01 | ≤0.025 |

| C | Ti | Co | N+O | H |

| ≤0.05 | Équilibré | ≤0.05 | ≤0.050 | ≤0.005 |

Dimensions et tolérances des tubes en nitinol

| OD (mm) | Tolérance sur le diamètre extérieur (mm) | Tolérance ID (mm) |

| OD≤0.3 | ±0.005 | ±0.010 |

| 0,3≤OD≤0,5 | ±0.007 | ±0.015 |

| 0,5≤OD≤1,5 | ±0.015 | ±0.020 |

| 1,5≤OD≤2,5 | ±0.020 | ±0.030 |

| 2,5≤OD≤3,5 | ±0.020 | ±0.040 |

Avantages des tubes en nitinol

- Surface lisse du produit

- Grande précision dimensionnelle

- Bonne plasticité

- Déformation à froid jusqu'à 40% ou plus

- Excellente superélasticité après traitement

Tube en nitinol Finition de surface

- Noir: La surface est "telle que sertie" ou "telle qu'étirée", conservant une couche de lubrifiants et d'oxydes de traitement.

- Nettoyé: La surface est nettoyée chimiquement pour éliminer tous les lubrifiants et oxydes.

- Sol: La surface est décentrée afin d'éliminer tous les revêtements et d'obtenir un contrôle précis des dimensions.

Applications des tubes en nitinol

- Domaine médical: Les tubes en nitinol sont souvent utilisés comme dispositifs médicaux tels que les endoprothèses vasculaires, les fils-guides ou les cathéters en raison de leur grande élasticité.

- Aérospatiale: L'effet de mémoire de forme des tubes en nitinol peut être utilisé pour fabriquer des composants structurels variables dans les engins spatiaux, tels que les unités d'entraînement ou les raccords de tuyauterie.

- Industrie et ingénierie: Les tubes en nitinol permettent de fabriquer des valves ou des actionneurs sensibles à la température grâce à leur effet de mémoire de forme. Leurs propriétés superélastiques les destinent à l'amortissement des vibrations ou des chocs.

- Robotique et automatisation: Dans les micro-robots ou les appareils bioniques, les tubes en nitinol peuvent être utilisés comme simulateurs de muscles pour assurer un contrôle précis des mouvements.

Emballage des tubes en nitinol

Les produits Nitinol Tube sont soigneusement placés dans des caisses ou des cartons en bois, avec un support supplémentaire en matériaux souples, afin d'éviter qu'ils ne se déplacent pendant le transport. Cette méthode d'emballage garantit l'intégrité des produits tout au long du processus de livraison.

Télécharger

Obtenir un devis

Nous vérifierons et vous contacterons dans les 24 heures.

Autres produits tubulaires

Heeger Metal fournit des tubes et tuyaux personnalisés de haute qualité dans une variété de matériaux, notamment l'acier inoxydable, le titane, les alliages de nickel, etc. Nos tubes et tuyaux de précision sont disponibles dans différentes tailles et formes, idéales pour des applications dans des industries telles que l'aérospatiale, l'automobile, l'énergie et le traitement chimique. Que vous ayez besoin de tubes sans soudure, de tubes soudés ou de solutions sur mesure, nous fournissons des produits conçus pour répondre à vos spécifications exactes avec une solidité supérieure, une résistance à la corrosion et des performances durables.

Autres produits en nitinol

Heeger Metal propose une gamme complète de produits en alliage de titane, y compris NitinolLes produits de cette catégorie se présentent sous diverses formes, telles que des poudres et des pièces finies, avec des options de personnalisation disponibles. Connu pour ses propriétés uniques de mémoire de forme, sa solidité exceptionnelle, sa résistance à la corrosion et sa biocompatibilité, Nitinol est idéal pour les appareils médicaux, l'aérospatiale, la robotique et d'autres applications d'ingénierie avancée.