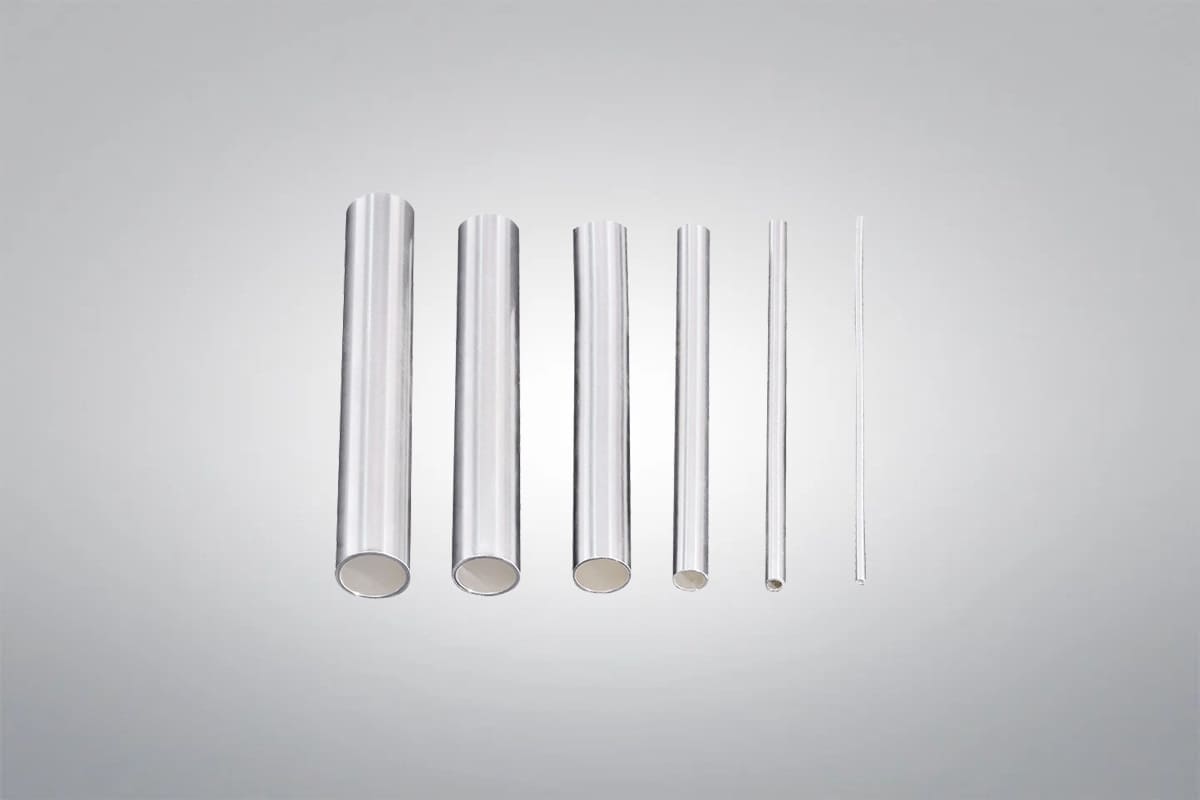

Tube en argent

Tube en argent

Pureté : ≥99.95%, ou personnalisée

Le tube d'argent est fabriqué à partir d'argent métal de haute pureté grâce à des techniques précises. Il offre une excellente conductivité électrique, une résistance à la corrosion et une conductivité thermique, et est disponible dans différentes spécifications. En tant que fournisseur et fabricant de premier plan de produits en argent de première qualité, Heeger Metal s'appuie sur une technologie de pointe pour fournir des tubes d'argent de haute qualité pour diverses applications.

Ou envoyez-nous un courriel à l'adresse suivante sales@heegermaterials.com.Fiche technique du tube d'argent

| Code de référence : | HMSI2711 |

| CAS : | 7440-22-4 |

| La pureté : | ≥99.95%, ou sur mesure |

| Densité : | 10,503 g/cm3 |

| Point de fusion : | 961.78℃ |

| Point d'ébullition : | 2162℃ |

| État de livraison : | État dur, semi-dur ou mou selon les besoins spécifiques |

| Tempérer : | Recuit ou non recuit |

Description du tube d'argent

L'argent (Ag) est un métal précieux connu pour sa conductivité électrique, sa conductivité thermique et sa réflectivité les plus élevées de tous les métaux. En outre, il présente une excellente résistance à la corrosion et à l'oxydation. Le tube d'argent est fabriqué à partir d'argent métal de haute pureté, largement utilisé dans les échangeurs de chaleur, les contacts électriques et les appareils médicaux. Heeger Metal peut fournir des tubes d'argent de haute qualité dans diverses spécifications et des solutions personnalisées pour répondre aux applications industrielles et de recherche, garantissant des performances optimales et un bon rapport coût-efficacité.

Tolérances des tubes en argent

| Diamètre extérieur | =<2mm | ±0,05 mm |

|---|---|---|

| Diamètre extérieur | 2mm - 5mm | ±0,1 mm |

| Diamètre extérieur | >5mm | ±5% |

| Épaisseur de la paroi | ±10% |

Procédés de fabrication des tubes en argent

- Fusion: Les lingots ou les pastilles d'argent sont fondus dans un four à haute température pour former une masse d'argent en fusion. Dans certains cas, de petites quantités d'autres métaux peuvent être ajoutées pour améliorer les propriétés du matériau.

- Casting: L'argent en fusion est coulé dans des moules pour créer une forme cylindrique, formant ainsi la billette initiale du tube d'argent. Le processus de coulée permet d'obtenir une forme de tube de base avant de poursuivre le traitement.

- Extrusion: La billette d'argent est ensuite chauffée et introduite dans une machine d'extrusion. Grâce à l'extrusion à haute pression, l'argent est forcé à travers une filière pour former de longs tubes du diamètre et de l'épaisseur souhaités. Cette étape est cruciale pour façonner le tube et garantir une épaisseur de paroi uniforme.

- Recuit: Après l'extrusion, le tube d'argent est recuit en le chauffant dans un four afin de réduire les tensions internes et d'améliorer la ductilité. Ce processus rend l'argent plus malléable, ce qui permet de le façonner et de le travailler facilement.

- Dessin: Les tubes d'argent sont ensuite étirés à travers une série de matrices afin de réduire leur diamètre et d'augmenter leur longueur. Cette étape permet d'affiner les dimensions du tube et d'améliorer l'état de surface.

- Découpe et dimensionnement: Après avoir été dessinés, les tubes d'argent sont coupés à des longueurs spécifiques. Cette opération peut être effectuée à l'aide d'outils de coupe de précision ou de scies afin d'obtenir des dimensions précises.

- Finition de surface: Les tubes subissent divers traitements de finition de surface, tels que le polissage ou le revêtement, afin d'en améliorer l'aspect et de prévenir l'oxydation. La surface peut être lissée pour obtenir une finition brillante ou mate, en fonction de l'utilisation prévue.

- Contrôle de la qualité: Tout au long du processus de production, des contrôles de qualité sont effectués pour s'assurer que les tubes d'argent répondent aux spécifications en termes de taille, de résistance, de finition de surface et de conductivité.

Applications du tube d'argent

- Électronique: Les tubes d'argent sont couramment utilisés dans les composants électriques en raison de leur excellente conductivité. Ils sont utilisés dans les connecteurs, les condensateurs, les résistances et d'autres composants électroniques qui nécessitent une conductivité et une durabilité élevées.

- Dispositifs médicaux: Les tubes en argent sont utilisés dans les dispositifs médicaux tels que les cathéters, les instruments chirurgicaux et les implants en raison des propriétés antimicrobiennes de l'argent. Leur solidité, combinée à leur biocompatibilité, en fait un matériau idéal pour les applications médicales.

- Échangeurs de chaleur: Les tubes en argent sont utilisés dans les échangeurs de chaleur en raison de leur conductivité thermique élevée. Ils sont efficaces pour transférer la chaleur dans diverses industries, y compris les systèmes de chauffage, de ventilation et de climatisation, la réfrigération et les centrales électriques.

- Dispositifs optiques: Les tubes d'argent sont utilisés dans les appareils optiques haut de gamme tels que les télescopes, les microscopes et les caméras pour leur capacité à réfléchir la lumière et leur surface lisse et durable.

- Aérospatiale: En raison de leur rapport poids/résistance et de leur résistance à la corrosion, les tubes d'argent sont utilisés dans les applications aérospatiales, en particulier dans les composants qui exigent précision et fiabilité.

Emballage des tubes en argent

Silver Tube est soigneusement placé dans des caisses en bois ou des cartons avec des matériaux souples supplémentaires pour le soutenir et éviter qu'il ne se déplace pendant le transport. Cette méthode d'emballage garantit l'intégrité des produits tout au long du processus de livraison.

Propriétés d'argent

Télécharger

Obtenir un devis

Nous vérifierons et vous contacterons dans les 24 heures.

Autres produits tubulaires

Heeger Metal fournit des tubes et tuyaux personnalisés de haute qualité dans une variété de matériaux, notamment l'acier inoxydable, le titane, les alliages de nickel, etc. Nos tubes et tuyaux de précision sont disponibles dans différentes tailles et formes, idéales pour des applications dans des industries telles que l'aérospatiale, l'automobile, l'énergie et le traitement chimique. Que vous ayez besoin de tubes sans soudure, de tubes soudés ou de solutions sur mesure, nous fournissons des produits conçus pour répondre à vos spécifications exactes avec une solidité supérieure, une résistance à la corrosion et des performances durables.