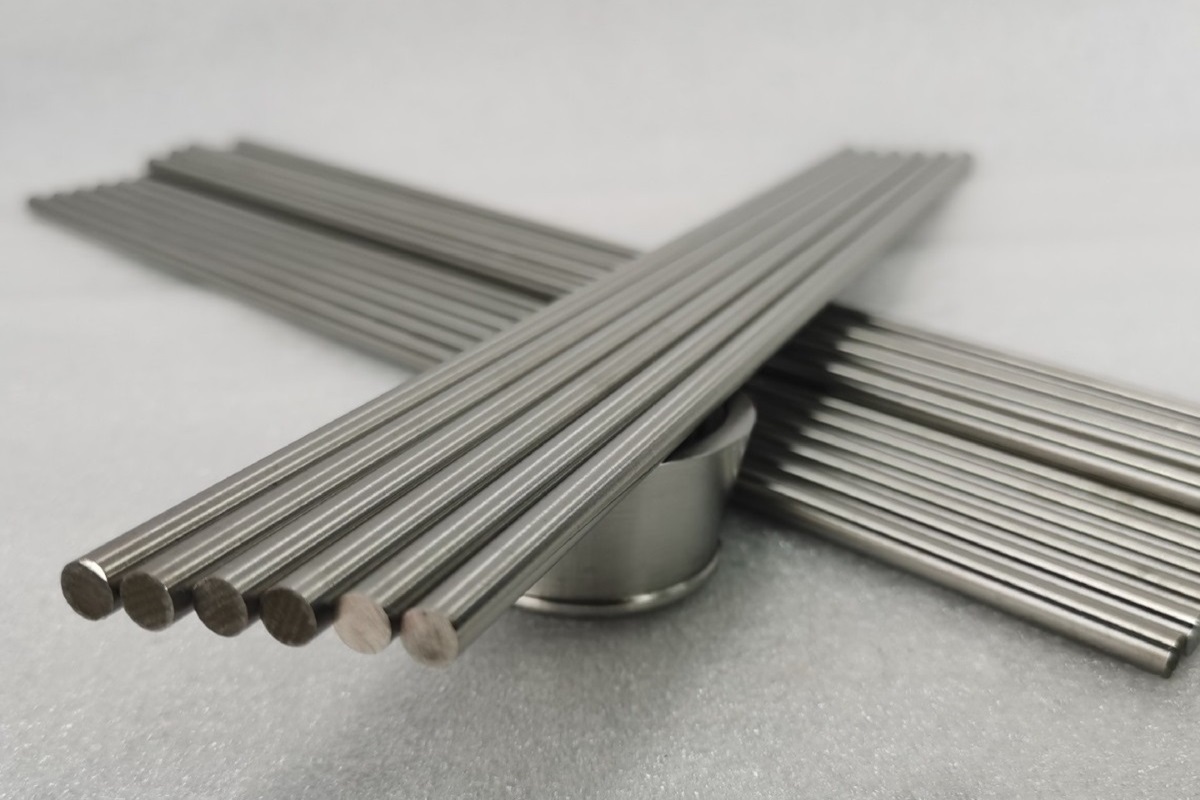

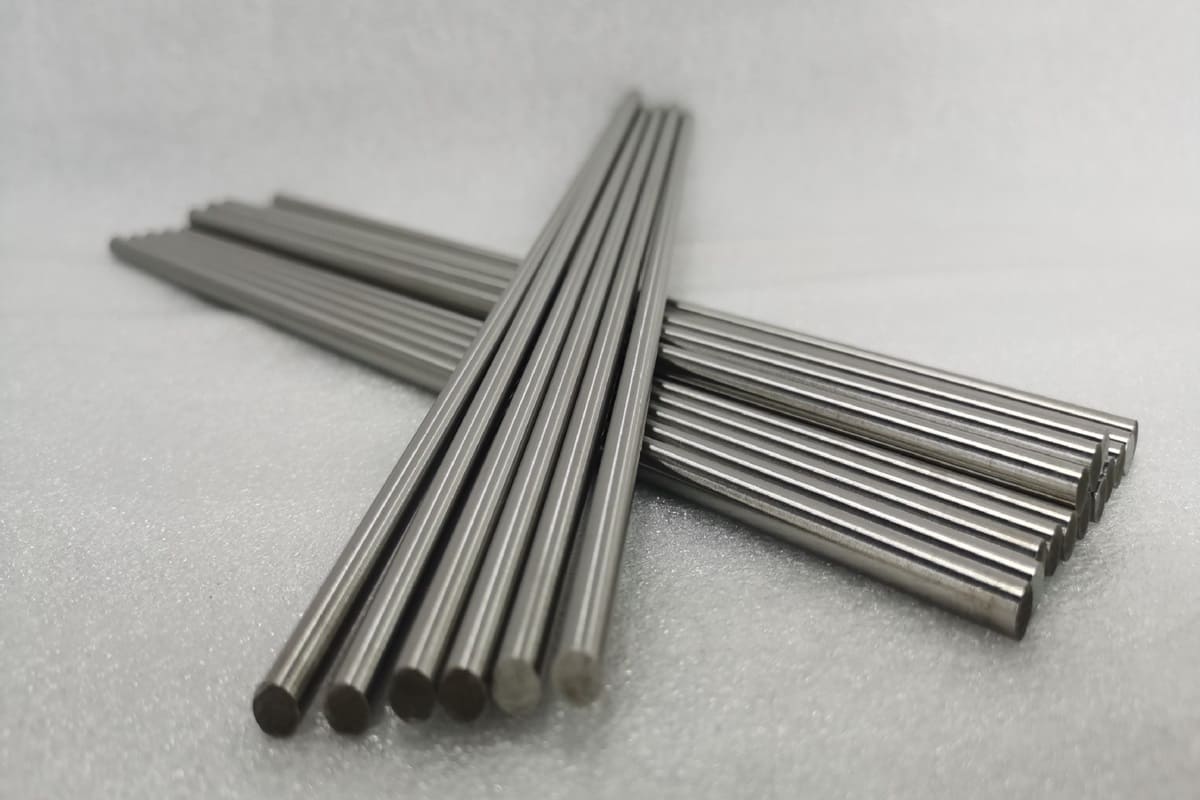

Tantalum Rod/Bar

Tantalum Rod/Bar

Standard: ASTM B365, ASTM F560 (Medical Grade)

Material: R05200 R05400

Tantalum Rod/Bar is manufactured in compliance with ASTM B365 standards. Our product range also includes Tantalum Alloy Rods, such as Ta10W and Ta2.5W Rods.

Or email us at max@heegermaterials.com.Tantalum Rod/Bar Data Sheet

| Reference: | HMTA0007 |

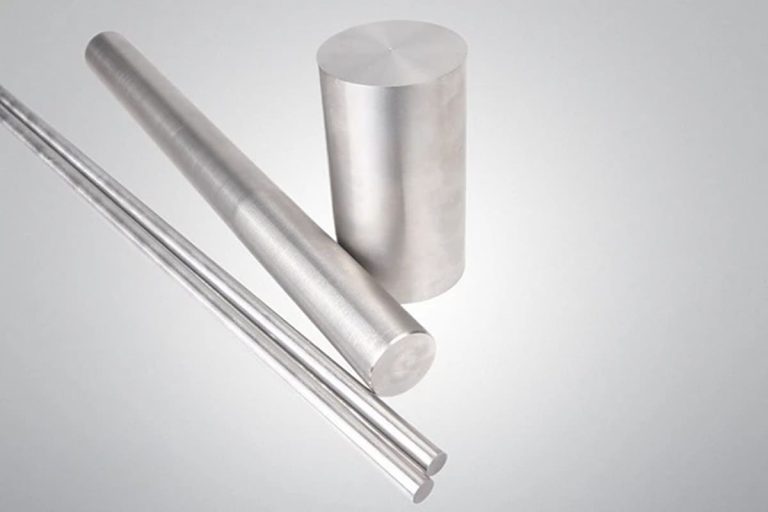

| Dimensions: | Rod: 0.125″ – 8″ Dia. x < 10′ L Bar: 0.1″ x 0.1″ x L |

| Standard: | ASTM B365, ASTM F560 (Medical Grade) |

| Material: | R05200, R05400 |

| Purity: | 99%, 99.9%, 99.95%, 99.99%, 99.999% |

| Temper: | Annealed or Unannealed |

Tantalum Rod and Tantalum Bar

Tantalum Rod is made from high-purity tantalum metal, known for its excellent corrosion resistance, high melting point (around 3000℃), and outstanding oxidation resistance. It is commonly used to produce high-performance capacitors, transistors, chemical reactors, and high-temperature components.

Tantalum Bar has a square or rectangular cross-section. HM can provide custom sizes, shapes, and compositions to meet specific demands.

Tantalum Rod Applications

- Electronics: These are used as electrode materials for capacitors.

- Aerospace: Used to manufacture engine components and gas turbines.

- Chemical industry: Used as an ideal material for handling strong acids and alkalis.

- Medical: Used in the production of artificial joints and medical devices.

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Rod Packaging

The Tantalum Rod and Tantalum Bar are carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tantalum Rod In Stock

|

Catalog Number |

Chemical Formula |

Diameter |

Purity |

Temper |

|

TA007910 |

Ta |

1.0 mm |

99.95% |

As Rolled |

|

TA007915 |

Ta |

1.5 mm |

99.95% |

Annealed |

|

TA007917 |

Ta |

1.7 mm |

99.95% |

Annealed |

|

TA007920 |

Ta |

2.0 mm |

99.95% |

Annealed |

|

TA007926 |

Ta |

3.0 mm |

99.95% |

Annealed |

|

TA007930 |

Ta |

5.0 mm |

99.95% |

Annealed |

|

TA007935 |

Ta |

6.35 mm |

99.95% |

Annealed |

|

TA007940 |

Ta |

10.0 mm |

99.95% |

Annealed |

|

TA007942 |

Ta |

12.7 mm |

99.95% |

Annealed |

|

TA007945 |

Ta |

16 mm |

99.95% |

As drawn |

|

TA007948 |

Ta |

18 mm |

99.95% |

Annealed |

|

TA007950 |

Ta |

20.0 mm |

99.95% |

Annealed |

|

TA007955 |

Ta |

25 mm |

99.95% |

As Rolled |

|

TA007960 |

Ta |

30.0 mm |

99.95% |

Unannealed |

|

TA007961 |

Ta |

30 mm |

99.95% |

As Rolled |

|

TA007970 |

Ta |

40.0 mm |

99.95% |

Unannealed |

|

TA007972 |

Ta |

50 mm |

99.95% |

Annealed |

|

TA007975 |

Ta |

75 mm |

99.95% |

Annealed |

|

TA007995 |

Ta |

100 mm |

99.95% |

As Rolled |

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tantalum Products

Heeger Metal offers a comprehensive range of tantalum and tantalum alloy products, renowned for their outstanding corrosion resistance, high melting point, and stability in harsh environments. These characteristics make them ideal for demanding applications in the aerospace, electronics, and chemical processing industries. Our high-purity tantalum materials deliver exceptional performance and reliability in challenging conditions.

Other Rod/Bars Products

Heeger Metal supplies refractory metal and alloy rods/bars made from high-performance materials like tungsten, molybdenum, and tantalum. These rods offer excellent strength, high melting points, and resistance to wear and corrosion, making them ideal for aerospace, electronics, and high-temperature applications. Available in various sizes, they can be customized to meet specific needs.