Tantalum Foil/Strip/Ribbon

Tantalum Foil/Strip/Ribbon

Standard: ASTM B365, ASTM F560 (Medical Grade), ASTM B708

Material: R05200, R05400, R05252, R05255, R05240

Tantalum Foil/Strip/Ribbon is a thin sheet of tantalum material known for its excellent corrosion resistance, high melting point, and outstanding thermal and electrical conductivity. As a leading supplier and manufacturer of premium tantalum products, Heeger Materials leverages advanced machining centers to deliver high-precision tantalum and tantalum alloy foil/strip/ribbon for wide ranges of applications.

Or email us at max@heegermaterials.com.Tantalum Foil/Strip/Ribbon Data Sheet

| Reference: | HMTA0001 |

| Dimensions: | Thickness: 0.001″-0.1875″ Width: <6″ Length: TBD (To Be Determined) |

| Standard: | ASTM B708, ASTM B365, ASTM F560 (Medical Grade) |

| Material: | R05200, R05400, R05252, R05255, R05240 |

| Purity: | 99%, 99.9%, 99.95%, 99.99%, 99.999% |

| Temper: | Annealed or Unannealed |

Tantalum Foil and Tantalum Strip

Tantalum and Tantalum Alloy foil, strip, and ribbon are high-performance materials made of high-purity tantalum, known for their excellent corrosion resistance, high melting point, and good ductility. These materials are produced through rolling and cold-working processes, followed by annealing for improved strength. Tantalum’s unique properties make it ideal for use in harsh chemical environments, high-temperature applications, and electronic components like capacitors. It is also biocompatible, making it suitable for medical implants.

Tantalum Foil and Strip Specifications

| Product | Thickness (mm) | Width (mm) | Length (mm) |

| Foil | 0.025~0.09 | <150 | >200 |

| 0.1~0.5 | 50~300 | 100~2000 | |

| Strip | 0.025 | 1~1.5 | ≤50000 |

- *Please check the tantalum sheet if the width is >6″.

- *Please check the tantalum plate if the thickness is >0.1875″.

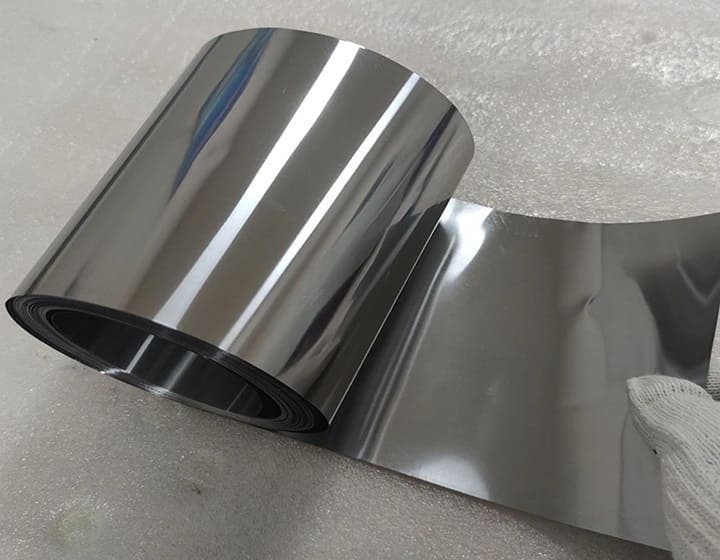

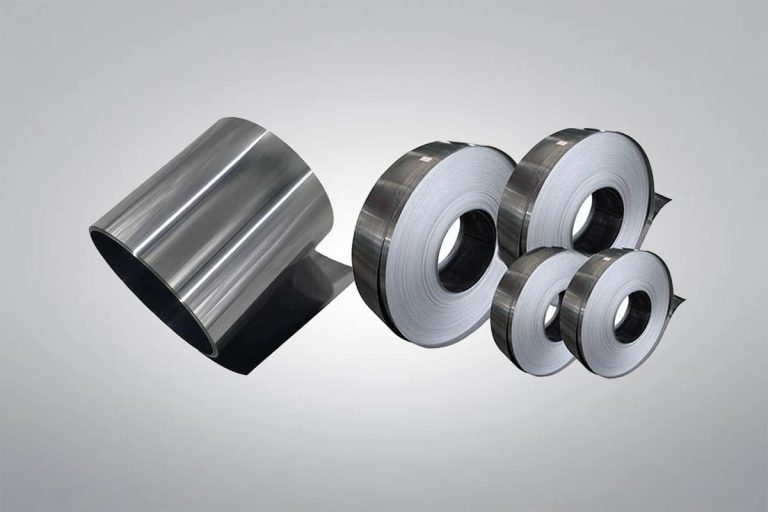

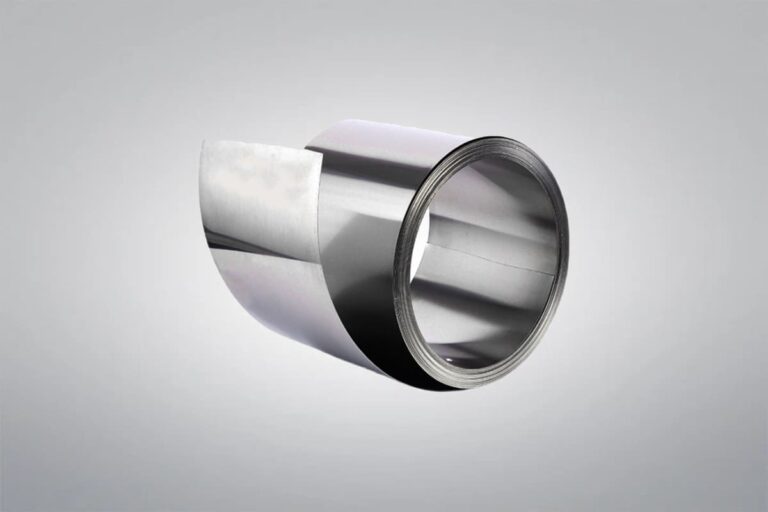

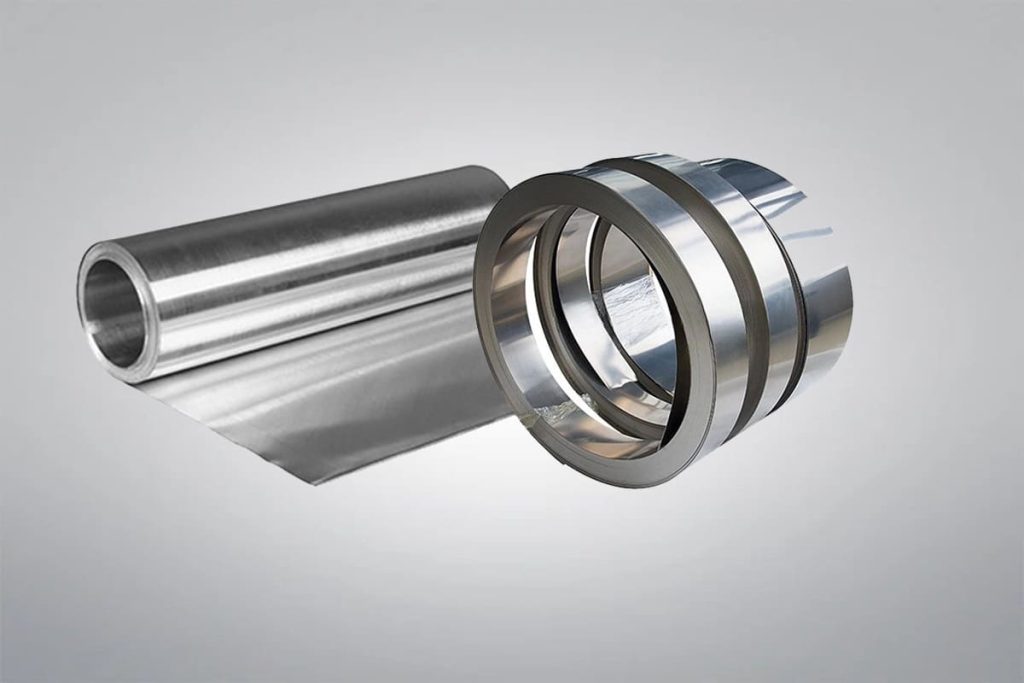

Tantalum Foil Tantalum Strip/Ribbon Tantalum Strip/Ribbon

Tantalum Foil, Strip, and Ribbon Tolerances

Tantalum foil, strip, and ribbon are produced with precise tolerances to meet specific application requirements. Tolerances typically cover thickness, width, and length, ensuring that the material fits the intended design and performance criteria. Custom tolerances can be specified depending on the customer’s needs.

| Thickness (mm) | Tolerances for Thickness (mm) | Width (mm) | Tolerances for Width (mm) | Length (mm) | Tolerances for Length (mm) | |

| Grade 1 | Grade 2 | |||||

| 0.025~0.07 | ±0.005 | ±0.006 | 70~150 | ±2.0 | ≥1000 | — |

| >0.07~0.09 | ±0.006 | ±0.008 | 70~150 | ±2.0 | ≥1000 | — |

| 0.1~0.20 | ±0.015 | ±0.02 | 50~300 | ±2.0 | 100~2000 | ±3.0 |

| >0.2~0.30 | ±0.02 | ±0.03 | 50~300 | ±2.0 | 100~2000 | ±3.0 |

| >0.30~0.50 | ±0.03 | ±0.04 | 50~500 | ±2.0 | 100~2000 | ±3.0 |

| >0.50~0.80 | ±0.04 | ±0.06 | 50~500 | ±2.0 | 50~1200 | ±3.0 |

| >0.80~1.0 | ±0.06 | ±0.08 | 50~500 | ±2.0 | 50~1200 | ±3.0 |

Tantalum Foil/Strip/Ribbon Production Process

Tantalum foil, strip, and ribbon are made of high-purity tantalum and tantalum alloy ingots through hot rolling, cold rolling, and annealing to achieve the desired thickness, strength, and ductility. Additional treatments such as polishing and chemical etching may be applied to meet specific requirements for particular applications. Here is the typical production process:

- Raw Material Selection: Tantalum ingots or powder are selected based on purity and quality requirements.

- Melting and Casting: Tantalum is melted in a vacuum or inert gas atmosphere and cast into ingots.

- Hot Rolling: The ingot is heated and passed through rollers to reduce the thickness and achieve the desired shape.

- Cold Rolling: Further reduction of thickness is achieved at room temperature, improving the material’s surface finish and mechanical properties.

- Annealing: The material is heat-treated to relieve internal stresses and improve ductility.

- Pickling and Polishing: The surface is cleaned using chemical treatments to remove oxides and improve appearance.

- Final Cutting: The material is cut into foil, strip, or ribbon forms, depending on the specific application requirements.

Tantalum Foil/Strip/Ribbon Applications

- Electronics: Tantalum foil/strip/ribbon, known for its excellent conductivity and stability, is commonly used to manufacture capacitors, vacuum tubes, and other high-quality electronic devices.

- Semiconductor Industry: Due to its superior conductivity and corrosion resistance, tantalum foil/strip/ribbon is widely used to produce semiconductor devices.

- Aerospace: Tantalum foil/strip/ribbon demonstrates outstanding stability under high-temperature and high-pressure conditions, making it ideal for use in aerospace engines and nuclear reactor fuel rods.

- Laboratory Equipment: Tantalum foil/strip/ribbon, with its good ductility and toughness, is frequently used to manufacture various laboratory apparatus.

- Superalloys and Electron Beam Melting: Tantalum foil/strip/ribbon is employed in producing superalloys and in electron beam melting equipment.

- Metallurgy and Machining: In metallurgy and machining, tantalum foil/strip/ribbon is commonly used to manufacture high-strength and corrosion-resistant components.

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Foil/Strip/Ribbon Packaging

The Tantalum Foil/Strip/Ribbon is carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tantalum Products

Heeger Metal offers a comprehensive range of tantalum and tantalum alloy products, renowned for their outstanding corrosion resistance, high melting point, and stability in harsh environments. These characteristics make them ideal for demanding applications in the aerospace, electronics, and chemical processing industries. Our high-purity tantalum materials deliver exceptional performance and reliability in challenging conditions.

Other Foil/Strip/Ribbon Products

Heeger Metal provides a wide range of metal foil, metal strip, and metal ribbon products. Our foil and strip materials are precision-engineered for applications requiring high strength, flexibility, and thermal stability, ideal for electronics, aerospace, and industrial sectors. Whether you need custom metal ribbons or thin metal strips, our products deliver superior performance and reliability.