Tungsten Crucible

Tungsten Crucible

Material: Pure Tungsten, Tungsten Heavy Alloy (WNiCu, WNiFe)

Purity: 99%-99.999%

Tungsten Crucible is a high-temperature resistant container, which is ideal for sapphire crystal growth and rare earth material melting. It can be used in a vacuum and inert gas environment at a temperatures below 2600 ℃. As a leading supplier and manufacturer of premium tungsten products, Heeger Materials leverages advanced machining centers to deliver high-precision tungsten and tungsten alloy crucibles for wide ranges of applications.

Or email us at max@heegermaterials.com.Tungsten Crucible Data Sheet

| Reference: | HMWW1118 |

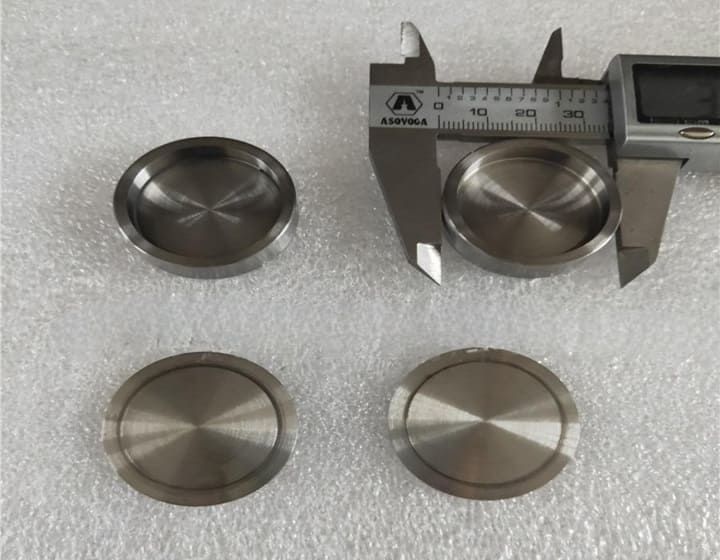

| Dimensions: | Diameter: 10-500 mm Wall Thickness: 8-20 mm Height: 10-750 mm |

| Material: | Tungsten and Tungsten Heavy Alloy |

| Shape: | Cylinder, Square, Rectangular, Tapered, Threaded, or customized according to specific drawings |

| Purity: | 99%, 99.9%, 99.95%, 99.99%, 99.999% |

| Surface: | Grinding, Finish turning |

| Temper: | Annealed or Unannealed |

Tungsten Crucible

Tungsten Crucibles are high-temperature resistant vessels made of high-purity tungsten material. Additionally, the inclusion of certain rare earth elements in the production of pure tungsten crucibles can enhance their oxidation resistance, thereby extending the product’s service life. They are generally cylindrical in shape, with diameters ranging from 10-500 mm, heights ranging from 10-750 mm, and wall thicknesses ranging from 8-20 mm. HM can also customize the size, shape, and tolerance to meet specific requirements.

Tungsten Crucible Material Chemical Composition

| W (>%) | Chemical Content (<%) | |||||||||||

| 99.999 W1 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | Ta | Na |

| 0.0001 | 0.00005 | 0.000005 | 0.000005 | 0.00005 | 0.00001 | 0.00005 | 0.00005 | 0.00003 | 0.000005 | 0.0001 | 0.00005 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.000005 | 0.00001 | 0.00005 | 0.00005 | 0.000005 | 0.00001 | 0.00001 | 0.000005 | 0.000007 | 0.00001 | 0.000005 | 0.000005 | |

| 99.99 W2 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | O | Na |

| 0.0001 | 0.00045 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0005 | 0.0040 | 0.0009 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0002 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | |

| 99.95 W3 | Fe | Ca | P | Sn | Al | Ni | N | Sb | Si | O | Pb | As |

| 0.005 | 0.003 | 0.001 | 0.0001 | 0.002 | 0.003 | 0.003 | 0.001 | 0.003 | 0.003 | 0.0001 | 0.002 | |

| Mg | C | Bi | Mo | |||||||||

| 0.002 | 0.005 | 0.0001 | 0.001 | |||||||||

Tungsten Crucible Stock Dimensions

| Diameter(mm) | Wall Thickness(mm) | Height(mm) | Roughness | |||

| Diameter | Tolerance | Wall Thickness | Tolerance | Height | Tolerance | |

| 30~50 | ±0.5 | 2~10 | ±0.5 | 20~80 | ±0.5 | Ra≤1.6 |

| 50~100 | ±1 | 3~15 | ±1 | 20~80 | ±1 | Ra≤1.6 |

| 100~150 | ±1 | 5~15 | ±1 | 20~500 | ±1.5 | Ra≤1.6 |

| 150~250 | ±1 | 5~20 | ±1 | 30~500 | ±1.5 | Ra≤2.5 |

| 250~350 | ±1.5 | 8~30 | ±1 | 30~500 | ±2 | Ra≤2.5 |

| 350~450 | ±1.5 | 8~30 | ±1 | 30~550 | ±2 | Ra≤2.5 |

Tungsten Crucible Properties

- High density

- High melting point

- High boiling point

- Low vapor pressure

- Slow evaporation rate

- Low thermal expansion coefficient

- Good thermal conductivity

- Good corrosion and wear resistance

Tungsten Crucible Production Process

- Raw Material: Select high-purity tungsten powder.

- Powder Metallurgy: High-purity tungsten powder is mixed, pressed, and molded into the preliminary shape of the crucible. common methods include isostatic pressing and die pressing.

- Sintering: The molded tungsten crucible is placed in a high-temperature furnace and sintered under a vacuum or inert gas environment, usually at temperatures above 2000 ℃.

- Machining: After sintering, the crucible undergoes further machining, including turning, milling, and polishing, to achieve precise dimensions and surface smoothness.

- Surface Treatment: Coating, oxidation, or heat treatment to enhance the high-temperature resistance, corrosion resistance, and oxidation resistance.

Tungsten Crucible Types

Depending on the manufacturing process, tungsten crucibles can be classified into different types, as follows:

- Forged Type

- Sintered Type

- Welded Type

- Stamped Type

- Spin-formed Type

Tungsten Crucible Applications

- Rare earth smelting: Tungsten crucibles are commonly used in the smelting process of rare earth metals, capable of withstanding extremely high temperatures to ensure the stability and efficiency of the smelting process.

- Quartz Glass Production: In the melting process of quartz glass, tungsten crucibles are used as the core vessel to withstand high temperatures and reduce contamination of the glass.

- Crystal growth: Tungsten crucibles are widely used in sapphire single crystal growth furnaces to ensure the quality and success of the crystal growth process.

- Electronic Spraying: In the spraying process of electronic components, tungsten crucibles can withstand high temperatures and harsh chemical environments to ensure the quality of spraying.

Tungsten Crucible Packaging

The Tungsten Crucible is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tungsten Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tungsten Products

Heeger Metal provides a wide range of tungsten and tungsten alloy products, from powders to finished components, with customization options available. Known for their outstanding strength, high melting point, and excellent wear and corrosion resistance, these materials are ideal for aerospace, electronics, and industrial applications. Our high-purity tungsten ensures exceptional durability and performance in even the most extreme conditions.

Other Crucible Products

Heeger Metal specializes in high-quality customized metal crucibles and alloy crucibles, designed to withstand extreme temperatures for melting and casting applications. Made from durable materials, our crucibles ensure excellent performance in industries such as metallurgy and material science. For more details or custom solutions, feel free to contact us.