Tungsten Powder

Tungsten Powder

CAS: 7440-33-7

Purity: 99%-99.999%

Tungsten Powder is a high-purity material with a uniform particle size distribution and excellent flowability. It features high density, a high melting point, and exceptional corrosion resistance, widely used in electronics, aerospace, metallurgy, and cemented carbide production. As a leading supplier and manufacturer of premium tungsten products, Heeger Materials leverages advanced technology to deliver high-quality tungsten powder for wide ranges of applications.

Or email us at max@heegermaterials.com.Tungsten Powder Data Sheet

| Reference: | HMWW1113 |

| Material: | Pure Tungsten |

| Purity: | 99%, 99.9%, 99.95%, 99.99%, 99.999% |

| Particle Size: | Customized |

| CAS: | 7440-33-7 |

Tungsten Powder

Tungsten Powder is a grey-black powder with a metallic luster and a melting point as high as 3400°C. It is produced by reducing tungsten trioxide or ammonium paratungstate (APT), with purity influenced by factors such as the reduction temperature, the amount of reducing agent, the movement of the reaction vessel, and the gas flow rate. HM also can provide high-quality Spherical Tungsten Powder with various specifications for additive manufacturing industries.

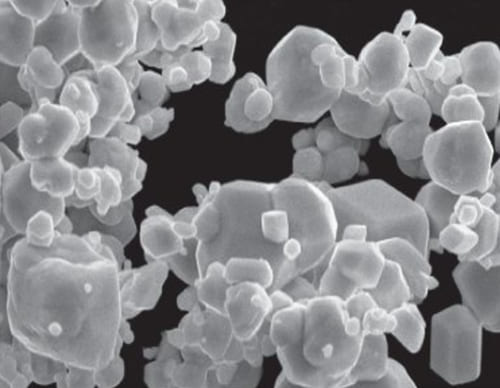

Tungsten Powder Tungsten Powder SEM

Tungsten Powder Chemical Composition

| W (>%) | Chemical Content (<%) | |||||||||||

| 99.999 W1 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | Ta | Na |

| 0.0001 | 0.00005 | 0.000005 | 0.000005 | 0.00005 | 0.00001 | 0.00005 | 0.00005 | 0.00003 | 0.000005 | 0.0001 | 0.00005 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.000005 | 0.00001 | 0.00005 | 0.00005 | 0.000005 | 0.00001 | 0.00001 | 0.000005 | 0.000007 | 0.00001 | 0.000005 | 0.000005 | |

| 99.99 W2 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | O | Na |

| 0.0001 | 0.00045 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0005 | 0.0040 | 0.0009 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0002 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | |

| 99.95 W3 | Fe | Ca | P | Sn | Al | Ni | N | Sb | Si | O | Pb | As |

| 0.005 | 0.003 | 0.001 | 0.0001 | 0.002 | 0.003 | 0.003 | 0.001 | 0.003 | 0.003 | 0.0001 | 0.002 | |

| Mg | C | Bi | Mo | |||||||||

| 0.002 | 0.005 | 0.0001 | 0.001 | |||||||||

Tungsten Powder Particle Size Distribution

| Size | Description | Typical Uses |

| 1-10 μm | Ultrafine grade | Additive manufacturing |

| 10-25 μm | Fine grade | Powder injection molding |

| 25-45 μm | Medium grade | Cutting tools |

| 45-150 μm | Coarse grade | Tungsten heavy alloys |

Tungsten Powder Physical Properties

| Item | Value | Significance |

| Particle Size | 1-150 μm | Smaller sizes improve sintering |

| Apparent Density | 3-4 g/cm3 | Indicating compaction properties |

| Tap Density | 9-11 g/cm3 | High packing density |

| Hall Flow Rate | 20-25 s/50g | Good flow reduces the risk of powder clogging and jamming. |

| O Content | <1000 ppm | Affecting ductility and strength |

Tungsten Powder Applications

- Cemented Carbide: Tungsten Powder is an important raw material for manufacturing cemented carbide.

- Electronics: Tungsten Powder is used to manufacture electrical contacts and electrodes in electronic devices.

- Aerospace: Tungsten Powder can be used to produce radiation shielding materials.

- Powder Metallurgy: Mixed with other metal powders, Tungsten Powder can be used to create a variety of tungsten alloys, such as tungsten-molybdenum alloys, tungsten-rhenium alloys, tungsten-copper alloys, and other high-density tungsten alloys.

- Thermal Spraying: Tungsten Powder is used in the thermal spraying process, widely used in the surface treatment of mechanical parts to form wear-resistant and corrosion-resistant coatings.

Tungsten Powder Packaging

The Tungsten Powder is carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tungsten Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Powder Products

Heeger Metal offers a comprehensive range of metal powder products, including spherical powders, and nano powders. Our high-quality metal powders are ideal for applications in 3D printing, powder metallurgy, electronics, and advanced manufacturing. These powders provide excellent consistency, flowability, and particle size distribution, ensuring superior performance in various industrial processes. Whether you need custom metal powders or standard alloy powders, our products meet the highest quality standards for precision and reliability.

Other Tungsten Products

Heeger Metal provides a wide range of tungsten and tungsten alloy products, from powders to finished components, with customization options available. Known for their outstanding strength, high melting point, and excellent wear and corrosion resistance, these materials are ideal for aerospace, electronics, and industrial applications. Our high-purity tungsten ensures exceptional durability and performance in even the most extreme conditions.