Niobium Wire

Niobium Wire

Standard: ASTM B392

Purity: 99.5%-99.99%

Niobium Wire is drawn from high-purity niobium rod with excellent strength, high temperature resistance, corrosion resistance, and good superconducting properties. We can supply niobium wire in straight, coil and spooled forms. As a leading supplier and manufacturer of premium niobium products, Heeger Materials leverages advanced machining centers to deliver high-precision niobium wire for wide ranges of applications.

Or email us at max@heegermaterials.com.Niobium Wire Data Sheet

| Reference: | HMNB1103 |

| Dimensions: | Diameter: 0.25-3 mm Length: TBD (To Be Determined) |

| Standard: | ASTM B392, ASTM B655/B655M |

| Material: | RO4200, RO4210, RO4251, RO4261, RO4295 |

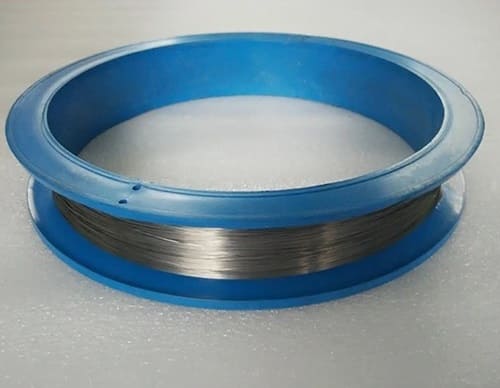

| Type: | Straight, Coil, or Spooled |

| Purity: | 99.5%-99.99% |

| Density: | 8.57 g/cm3 |

| Melting point: | 2468 ℃ |

| Temper: | Annealed or Unannealed |

Niobium Wire

Niobium is a rare, silvery-gray transition metal with excellent corrosion resistance and high strength at high temperatures. It is widely used in aerospace, nuclear energy, superconducting technology, and the chemical industry, and is ideal for producing superconducting materials due to its high superconducting transition temperature. HM can supply high-quality niobium wires with wide ranges of wire diameters. The customized solutions are available according to specific requirements.

Niobium Wire-Straight Wire Niobium Wire-Coiled Wire Niobium Wire-Spooled Wire

Niobium Wire Material Chemical Composition

| Material | Main Element (%) | Impurities (≤%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | Zr | Hf | O | C | H | N | |

| RO4200 | Bal. | 0.0040 | 0.0040 | 0.0020 | 0.0050 | 0.0050 | 0.0020 | 0.0700 | 0.0200 | 0.0200 | 0.0150 | 0.0040 | 0.0015 | 0.0030 |

| RO4210 | Bal. | 0.0100 | 0.0100 | 0.0050 | 0.0200 | 0.0100 | 0.0040 | 0.1000 | 0.0200 | 0.0200 | 0.0200 | 0.0100 | 0.0015 | 0.0100 |

| RO4251 | Bal. | 0.0050 | 0.0050 | 0.0050 | 0.0300 | 0.0100 | 0.0200 | 0.1000 | 0.8-1.2 | 0.0200 | 0.0150 | 0.0100 | 0.0015 | 0.0100 |

| RO4261 | Bal. | 0.0500 | 0.0050 | 0.0050 | 0.0500 | 0.0500 | 0.0300 | 0.5000 | 0.8-1.2 | 0.0200 | 0.0250 | 0.0100 | 0.0015 | 0.0100 |

| RO4295 (ASTM B655/B655M) | Bal. | — | — | — | 0.5000 | — | 0.7-1.3 | 0.5000 | 0.700 | 9-11 | 0.0250 | 0.0150 | 0.0015 | 0.0100 |

Niobium Wire Mechanical Properties

| Grade | Tensile strength psi(MPa), ≥ | Yield strength δ0.2, psi (MPa),≥ | Elongation in 1″/2″ gage length, %, ≥ | |

| >=0.010 | <0.010 | |||

| RO4200, RO4210 | 18000 (125) | 12000 (85) | 25 | 20 |

Niobium Wire Production Process

- Raw Material: Select high-purity niobium powder.

- Powder Metallurgy: Mix with binder and compact into a green billet.

- Sintering: High-temperature sintering to remove the binder and increase density.

- Drawing: Draw the rod to achieve the desired size and finish.

- Heat Treatment: Anneal to relieve stress and enhance properties.

- Surface Treatment: Clean and polish the surface.

- Cutting & Customization: Cut or customize according to requirements.

Niobium Wire Processing Method

- Sintering

- Forging

- Rotary Forging

- Rolling

- Polishing

Niobium Wire Surface Finish

Depending on the intended applications, niobium tubes and pipes have three main surface finishes as follows:

- Black: The surface is “as swaged” or “as drawn”, retaining a coating of processing lubricants and oxides.

- Cleaned: The surface is chemically cleaned to remove all lubricants and oxides.

Niobium Wire Applications

- Superconducting Materials: Niobium wires are widely used in the field of superconductivity and are commonly used to produce superconducting cables, superconducting magnets, and other devices, especially in particle gas pedals and nuclear magnetic resonance (NMR) instruments.

- Nuclear Industry: Niobium wires are commonly used as structural materials in nuclear reactors and nuclear fuel jacket materials due to their low neutron capture cross section and high corrosion resistance.

- Aerospace: Due to its excellent high-temperature strength and heat resistance, niobium wire is often used to manufacture high-temperature components, such as engine components for rockets and airplanes.

- Electronic Components: Niobium wires are used as acid and liquid metal corrosion-resistant materials in manufacturing boilers, heaters, and other equipment.

- Chemical Industry: Niobium wires are used as acid and liquid metal corrosion-resistant materials for boilers, heaters, and other equipment.

Niobium Wire Packaging

The Niobium Wire is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Niobium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

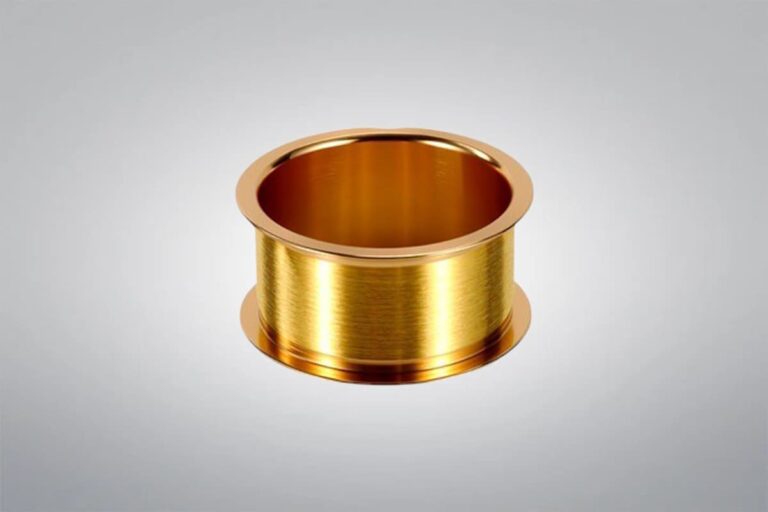

Other Wire Products

We specialize in providing high-quality custom wire products, including straight wires, coiled wires, and thermal spray wires. We offer various materials such as tungsten, molybdenum, nickel alloys, and more, ensuring precision and performance for diverse industrial applications. Whether you need wires for manufacturing, coating, or specialized coatings like thermal spraying, our custom wire solutions are designed to meet your specific requirements with superior strength and reliability.

Useful Information

Other Niobium Products

Heeger Metal offers a comprehensive range of niobium and niobium alloy products, including powders and finished parts, with customization options available. Known for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are ideal for aerospace, electronics, and chemical processing applications. Our high-purity niobium ensures reliable performance and durability in the most demanding environments.