Niobium Foil/Strip/Ribbon

Niobium Foil/Strip/Ribbon

Standard: ASTM B393, ASTM B654/B654M

Material: R04200, R04210, R04251, R04261, R04220, R04295

Niobium Foil/Strip/Ribbon is made of high purity niobium metal material through rolling, annealing, and surface finishing. It exhibits excellent ductility. As a leading supplier and manufacturer of premium niobium products, Heeger Materials leverages advanced machining centers to deliver high-precision niobium and niobium alloy foil/strip/ribbon for wide ranges of applications.

Or email us at max@heegermaterials.com.Niobium Foil/Strip/Ribbon Data Sheet

| Reference: | HMNB1099 |

| Dimensions: | Thickness: 0.001″-0.1875″ Width: <6″ Length: TBD (To Be Determined) |

| Standard: | ASTM B393, ASTM B654/B654M |

| Material: | R04200, R04210, R04251, R04261, R04220, R04295 (Nb1, Nb2, Nb1Zr Alloy, C103 Alloy, 45Nb Alloy (Nb-55Ti), Nb RRR (≥99.95%), Nb-7.5Ta, Nb-47Ti, Nb-50Ti, Nb-53Ti) |

| Purity: | 99.5%-99.99% |

| Temper: | Annealed or Unannealed |

Niobium Foil And Strip

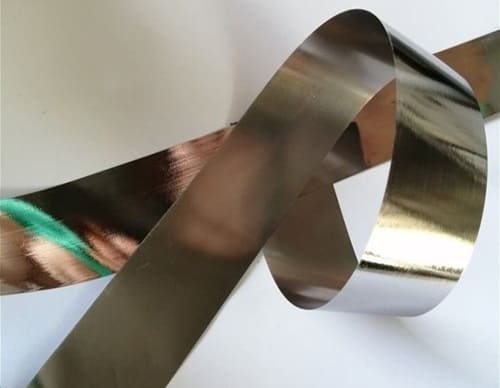

Niobium is a rare, silvery-gray transition metal with excellent corrosion resistance and high strength at high temperatures. Niobium foils, strips, and ribbons are made of high-purity niobium metal material with good strength, impact toughness, and good machinability. They are easy to deform even below room temperature. Whether for punching, cutting, deep drawing, or pressing, our niobium foil/strip/ribbon can be machined effortlessly to meet your specific requirements.

Niobium Foil Niobium Strip/Ribbon

Niobium Foil and Strip Specifications

| Type | Thickness (mm) | Width (mm) | Length (mm) |

| Foil | 0.03-0.09 | 30-150 | Customized |

| Strip | ≥0.05 | ≤280 | Customized |

Niobium Foil/Strip/Ribbon Material Chemical Composition

| Material | Main Element (%) | Impurities (≤%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | Zr | Hf | O | C | H | N | |

| RO4200 | Bal. | 0.0040 | 0.0040 | 0.0020 | 0.0050 | 0.0050 | 0.0020 | 0.0700 | 0.0200 | 0.0200 | 0.0150 | 0.0040 | 0.0015 | 0.0030 |

| RO4210 | Bal. | 0.0100 | 0.0100 | 0.0050 | 0.0200 | 0.0100 | 0.0040 | 0.1000 | 0.0200 | 0.0200 | 0.0200 | 0.0100 | 0.0015 | 0.0100 |

| RO4251 | Bal. | 0.0050 | 0.0050 | 0.0050 | 0.0300 | 0.0100 | 0.0200 | 0.1000 | 0.8-1.2 | 0.0200 | 0.0150 | 0.0100 | 0.0015 | 0.0100 |

| RO4261 | Bal. | 0.0500 | 0.0050 | 0.0050 | 0.0500 | 0.0500 | 0.0300 | 0.5000 | 0.8-1.2 | 0.0200 | 0.0250 | 0.0100 | 0.0015 | 0.0100 |

| R04220 | Bal. | 0.0050 | 0.0050 | 0.0030 | 0.0070 | — | 0.0050 | 0.1000 | 0.0100 | — | 0.0040 | 0.0030 | 0.0005 | 0.0030 |

| RO4295 | Bal. | — | — | — | 0.5000 | — | 0.7-1.3 | 0.5000 | 0.700 | 9-11 | 0.0250 | 0.0150 | 0.0015 | 0.0100 |

Niobium Foil/Strip/Ribbon Mechanical Properties

Mechanical Properties Of Annealed Condition

| Grade | Tensile strength psi(MPa), ≥ | Yield strength δ0.2, psi (MPa),≥ | Elongation in 1″/2″ gage length, %, ≥ | |

| >=0.010 | <0.010 | |||

| R04200, R04210 | 18000 (125) | 10500 (73) | 20 | 15 |

| R04251, R04261 | 28000 (195) | 18000 (125) | 20 | 15 |

| R04220 (RRR Grade) | 14000 (95) | 7200 (50) | 30 | 30 |

Mechanical Properties Of ASTM B654/B654M Condition

| Item | Tensile strength psi(MPa), ≥ | Yield strength δ0.2, psi (MPa),≥ | Elongation in 1″ gage length, %, ≥ |

| Thickness ≤0.050″ (1.27 mm) Room temperature | 56000 (385) | 40000 (275) | 20 |

| Thickness ≤0.050″ (1.27 mm) 2000±25 °F (1100±15 ℃) | 21000(145) | 16000 (110) | 20 |

| Thickness ≥0.050″ (1.27 mm) Room temperature | 54000 (370) | 38000 (260) | 20 |

| Thickness ≥0.050″ (1.27 mm) 2000±25 °F (1100± 15℃) | 21000 (145) | 16000 (110) | 20 |

Niobium Foil/Strip/Ribbon Production Process

Niobium foil, strip, and ribbon are made of high-purity niobium and niobium alloy ingots through hot rolling, cold rolling, and annealing to achieve the desired thickness, strength, and ductility. Additional treatments such as polishing and chemical etching may be applied to meet specific application requirements. Here is the typical production process:

- Raw Material Selection: Niobium ingots or powder are selected based on purity and quality requirements.

- Melting and Casting: Niobium is melted in a vacuum or inert gas atmosphere and cast into ingots.

- Hot Rolling: The ingot is heated and passed through rollers to reduce the thickness and achieve the desired shape.

- Cold Rolling: Further reduction of thickness is achieved at room temperature, improving the material’s surface finish and mechanical properties.

- Annealing: The material is heat-treated to relieve internal stresses and improve ductility.

- Pickling and Polishing: The surface is cleaned using chemical treatments to remove oxides and improve appearance.

- Final Cutting: The material is cut into foil, strip, or ribbon forms, depending on the specific application requirements.

Niobium Foil/Strip/Ribbon Applications

- Electronics Industry: Niobium foil/strip/ribbon is often used in microelectronics, silicon wafer manufacturing, flat panel displays, and storage technology.

- Chemical Processes: Niobium foil/strip/ribbon is commonly used as reaction vessels and heat exchanger tubes.

- High-pressure Sodium Lamps: Niobium foil/strip/ribbon can be used as reflective material for producing high-pressure sodium lamps.

- Aerospace Industry: Niobium foil/strip/ribbon is an important structural material for aviation and engines.

Niobium Foil/Strip/Ribbon Packaging

The Niobium Foil/Strip/Ribbon is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Niobium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Niobium Products

Heeger Metal offers a comprehensive range of niobium and niobium alloy products, including powders and finished parts, with customization options available. Known for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are ideal for aerospace, electronics, and chemical processing applications. Our high-purity niobium ensures reliable performance and durability in the most demanding environments.

Other Foil/Strip/Ribbon Products

Heeger Metal provides a wide range of metal foil, metal strip, and metal ribbon products. Our foil and strip materials are precision-engineered for applications requiring high strength, flexibility, and thermal stability, ideal for electronics, aerospace, and industrial sectors. Whether you need custom metal ribbons or thin metal strips, our products deliver superior performance and reliability.