Niobium Mesh

Niobium Mesh

Purity: 99.5%-99.99%

Material: R04200, R04210

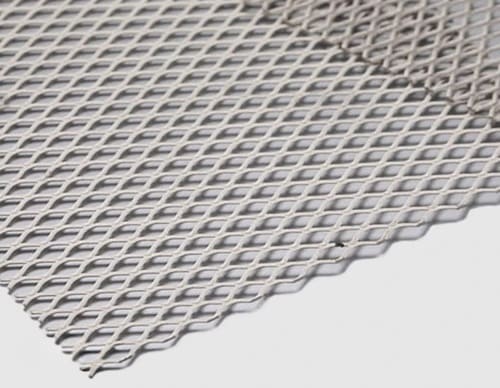

Niobium Mesh is made of high purity niobium metal material, exhibiting excellent high-temperature resistance, corrosion resistance, and high strength. As a leading supplier and manufacturer of premium niobium products, Heeger Materials leverages advanced machining centers to deliver high-precision niobium meshes for wide ranges of applications.

Or email us at max@heegermaterials.com.Niobium Mesh Data Sheet

| Reference: | HMNB1114 |

| Dimensions: | Wire Mesh: 20-180 mesh Expanded Mesh: Opening Size 1×1 mm to 50 x 50 mm (expanded by niobium sheets) |

| Type: | Expanded Mesh, Stamped Mesh, Wire Mesh, Platinized Mesh Anode |

| Material: | R04200, R04210 |

| Purity: | 99.5%-99.99% |

| Surface: | Black Oxide, Chemically Cleaned |

| Weaving Type: | Plain Weave, Twill Weave, etc. |

| Temper: | Annealed or Unannealed |

Niobium Mesh

Niobium is a rare, silvery-gray transition metal with excellent corrosion resistance and high strength at high temperatures. Niobium Meshes are made of high-purity niobium metal material with good strength and superior conductivity. HM is a professional supplier and manufacturer of high-quality and high-precision niobium meshes with various types and specifications, including wire mesh, sheet expanded mesh, stamped mesh, and platinized mesh. We can offer customized solutions according to specific requirements.

Niobium Mesh Platinized Niobium Mesh

Niobium Mesh Material Chemical Composition

| Material | Main Element (%) | Impurities (≤%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | Zr | Hf | O | C | H | N | |

| RO4200 | Bal. | 0.0040 | 0.0040 | 0.0020 | 0.0050 | 0.0050 | 0.0020 | 0.0700 | 0.0200 | 0.0200 | 0.0150 | 0.0040 | 0.0015 | 0.0030 |

| RO4210 | Bal. | 0.0100 | 0.0100 | 0.0050 | 0.0200 | 0.0100 | 0.0040 | 0.1000 | 0.0200 | 0.0200 | 0.0200 | 0.0100 | 0.0015 | 0.0100 |

Platinized Niobium Mesh Specification

| Material | Niobium (Nb) |

| Current Density | 10000A/m2 |

| Fluorine Ion Content | <500mg/L |

| Life Span | >10 months |

| Coating Oxide | Pt |

| Platinum Content | ≥10g/m2 |

| Coating Thickness | 0.5-15µm |

| Working Temperature | <80°C |

Platinized Niobium Mesh Features

Platinized Niobium Mesh combines the advantages of platinum and niobium, exhibiting excellent electrical conductivity, corrosion resistance, and high-temperature stability. The main characteristics are as follows:

- High-Temperature Resistance: The combination of platinum and niobium provides excellent high-temperature tolerance. Platinum-coated niobium mesh can maintain stable performance under high-temperature conditions, making it suitable for high-temperature reactions, smelting, and similar applications.

- Corrosion Resistance: The corrosion resistance of platinum allows the mesh to be used in harsh chemical environments, such as strong acids and alkalis, with high oxidation resistance.

- Excellent Electrical Conductivity: Platinum’s excellent electrical conductivity makes platinum-coated niobium mesh highly effective in electrochemical reactions, and ideal for use as electrode materials and in catalytic processes.

- High Mechanical Strength: Niobium has good mechanical strength and resistance to high pressure. Platinum-coated niobium mesh retains these properties, making it suitable for applications requiring high mechanical strength.

- Low Contact Resistance: The platinum coating reduces the contact resistance between the niobium mesh and other metal materials, improving electrical current transmission efficiency.

- Chemical Stability: The chemical stability of platinum allows the mesh to be used in extreme environments, such as in chlorine compounds, hydrogen gas, and other aggressive media.

- Stability and Long Life: Due to platinum’s resistance to oxidation, platinum-coated niobium mesh shows high stability and longevity during extended use.

Niobium Mesh Applications

- Chemical Industry: Niobium mesh is commonly used in chemical reactors, filters, heat exchangers, and other equipment to handle corrosive chemicals.

- Electronics Industry: Niobium mesh has good electrical conductivity and can be used to manufacture high-performance electronic components, such as battery electrodes, supercapacitors, sensors, and so on.

- Aerospace Industry: Niobium mesh is used in the aerospace industry as a material in high-temperature environments, such as components for rocket engines, and jet engines.

- Nuclear Industry: Niobium mesh is used as a radiation-resistant and stable material in nuclear reactors and for radiation protection.

- Medical: Niobium mesh is used as a radiation protection material in certain radiation therapy equipment.

- Precision Filters: Niobium mesh is often used as a high-precision filter for high-temperature or corrosive substances due to its high temperature and corrosion resistance.

Niobium Mesh Packaging

The Niobium Mesh is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Niobium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Niobium Products

Heeger Metal offers a comprehensive range of niobium and niobium alloy products, including powders and finished parts, with customization options available. Known for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are ideal for aerospace, electronics, and chemical processing applications. Our high-purity niobium ensures reliable performance and durability in the most demanding environments.

Other Mesh Products

Heeger Metal supplies a variety of metal mesh products and alloy mesh products. Our high-quality metal meshes are engineered for applications in industries like aerospace, electronics, filtration, and chemical processing, offering superior strength, corrosion resistance, and flexibility. Whether you need stamped meshes or woven metal mesh materials, our products deliver exceptional performance.