Niobium Custom Parts

Niobium Custom Parts

Standard: ASTM B393, ASTM B654/B654M

Material: R04200, R04210, R04251, R04261, R04295

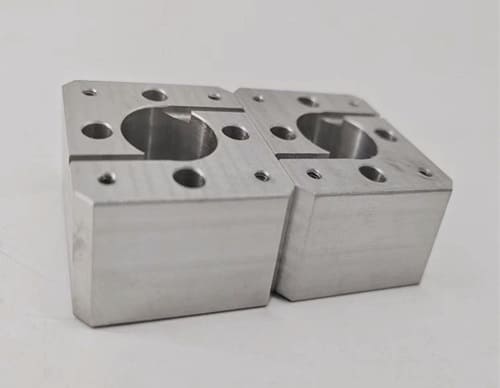

Niobium Custom Parts are made of high purity niobium metal material, exhibiting high temperature stability and excellent corrosion resistance. As a leading supplier and manufacturer of premium niobium products, Heeger Materials leverages advanced machining centers to deliver high-precision niobium and niobium alloy custom parts for wide ranges of applications.

Or email us at max@heegermaterials.com.Niobium Custom Parts Data Sheet

| Reference: | HMNB1116 |

| Material: | R04200, R04210, R04251, R04261, R04220, R04295 (Nb1, Nb2, Nb1Zr Alloy, C103 Alloy, 45Nb Alloy (Nb-55Ti), Nb RRR (≥99.95%), Nb-7.5Ta, Nb-47Ti, Nb-50Ti, Nb-53Ti) |

| Standard: | ASTM B393, ASTM B654/B654M |

| Purity: | 99.5%-99.99% |

| Dimensions: | The dimensions and shapes can be customized according to specific drawings with tight tolerances. |

| Type: | Ring, Flange, Fastener, Heater, or other complex shapes |

| Temper: | Annealed or Unannealed |

Niobium Custom Parts

Niobium is a rare, silvery-gray transition metal with excellent corrosion resistance and high strength at high temperatures. Niobium Custom Parts can be customized into various shapes and sizes to meet diverse industrial needs through precise machining and special alloy formulations. They possess high-temperature stability, corrosion resistance, and excellent electrical conductivity. They are widely applied in aerospace, military, electronics, metallurgy, and other industries. HM can supply high-precision niobium custom parts with tight tolerances based on specific drawings.

Niobium Custom Parts Material Chemical Composition

| Material | Main Element (%) | Impurities (≤%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | Zr | Hf | O | C | H | N | |

| R04200 | Bal. | 0.0040 | 0.0040 | 0.0020 | 0.0050 | 0.0050 | 0.0020 | 0.0700 | 0.0200 | 0.0200 | 0.0150 | 0.0040 | 0.0015 | 0.0030 |

| RO4210 | Bal. | 0.0100 | 0.0100 | 0.0050 | 0.0200 | 0.0100 | 0.0040 | 0.1000 | 0.0200 | 0.0200 | 0.0200 | 0.0100 | 0.0015 | 0.0100 |

| RO4251 | Bal. | 0.0050 | 0.0050 | 0.0050 | 0.0300 | 0.0100 | 0.0200 | 0.1000 | 0.8-1.2 | 0.0200 | 0.0150 | 0.0100 | 0.0015 | 0.0100 |

| RO4261 | Bal. | 0.0500 | 0.0050 | 0.0050 | 0.0500 | 0.0500 | 0.0300 | 0.5000 | 0.8-1.2 | 0.0200 | 0.0250 | 0.0100 | 0.0015 | 0.0100 |

| R04220 | Bal. | 0.0050 | 0.0050 | 0.0030 | 0.0070 | — | 0.0050 | 0.1000 | 0.0100 | — | 0.0040 | 0.0030 | 0.0005 | 0.0030 |

| RO4295 | Bal. | — | — | — | 0.5000 | — | 0.7-1.3 | 0.5000 | 0.700 | 9-11 | 0.0250 | 0.0150 | 0.0015 | 0.0100 |

Niobium Custom Parts Machining Services

Niobium Custom Parts require precision machining to meet strict tolerances and performance standards. The machining process involves cutting, shaping, and finishing. The niobium and its alloys’ high ductility allow us to create complex shapes and designs for specialized applications. HM can offer common machining services as follows:

- CNC Machining: Precision CNC milling and turning to create complex shapes and intricate features.

- Wire EDM: Used for cutting delicate and intricate parts with high precision.

- Surface Grinding: To achieve smooth, flat, and precise surfaces on niobium parts.

- Tapping & Threading: This is used to produce threaded holes or custom threads in niobium parts.

- Electropolishing: Enhancing the surface finish and corrosion resistance of the final parts.

Niobium Custom Parts Applications

Niobium Custom Parts have excellent high-temperature resistance, corrosion resistance, and electrical conductivity, and are widely used in the following fields:

- Aerospace

- Electronic Industry

- Medical Field

- Nuclear Energy Industry

- Chemical Industry

Niobium Custom Parts Packaging

The Niobium Custom Parts are carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Niobium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Niobium Products

Heeger Metal offers a comprehensive range of niobium and niobium alloy products, including powders and finished parts, with customization options available. Known for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are ideal for aerospace, electronics, and chemical processing applications. Our high-purity niobium ensures reliable performance and durability in the most demanding environments.

Other Custom Parts

Heeger Metal specializes in high-quality custom metal parts and alloy components, with a focus on refractory metals like tungsten, molybdenum, tantalum, and niobium. These materials offer exceptional resistance to high temperatures and corrosion, ideal for industries such as aerospace, electronics, and energy.