Zirconium Rod/Bar

Zirconium Rod/Bar

Material: Zr702, Zr704, Zr705

Standard: ASTM B550/B550M

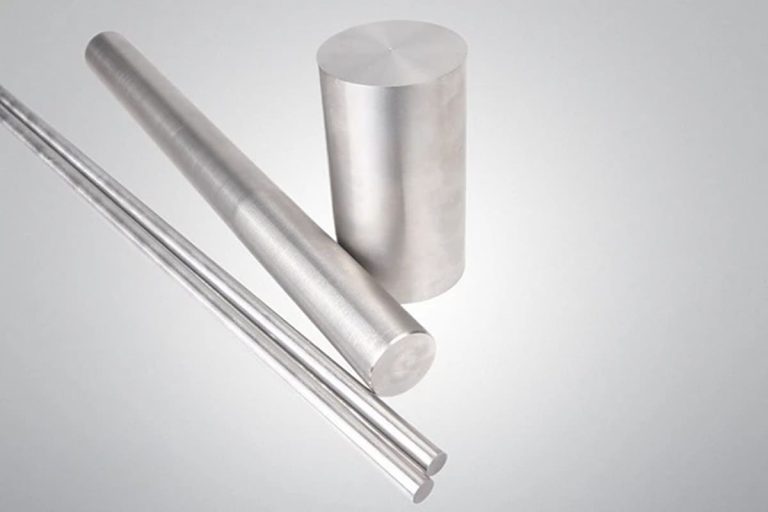

Zirconium Rod/Bar is drawn from zirconium metal, with excellent corrosion resistance, high-temperature tolerance, and radiation resistance. As a leading supplier and manufacturer of premium zirconium products, Heeger Materials leverages advanced technology to deliver high-purity zirconium rods and bars for wide ranges of applications.

Or email us at sales@heegermaterials.com.This product is currently unavailable. Please check other products. Thank you.

Zirconium Rod/Bar Data Sheet

| Reference: | HMZZ1143 |

| Material: | Zr702, Zr704, Zr705 |

| Purity: | 95%-99.5% |

| Diameter: | 7-150 mm, or customized |

| Standard: | ASTM B550/B550M |

| Temper: | Annealed and Unannealed |

Zirconium Rod And Bar

Zirconium (Zr) is an exceptionally corrosion-resistant metal, offering superior acid corrosion resistance compared to titanium and various steels, and is close to tantalum in performance. It demonstrates excellent resistance to hydrochloric acid at all concentrations and temperatures, even above its boiling point, and is highly resistant to crevice corrosion, pitting, and stress corrosion. It is highly suited for use in nuclear power rods due to its minimal neutron absorption cross-section and an impressive melting point of 1855 ℃. HM can supply high-quality zirconium rods and bars with various specifications for multiple applications.

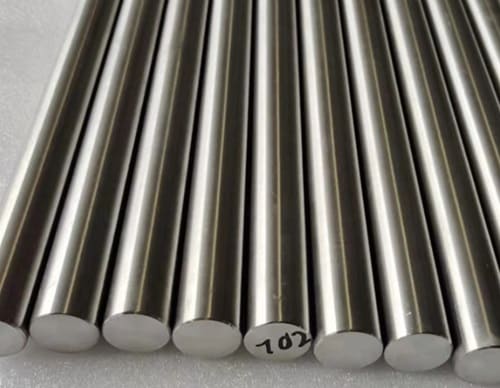

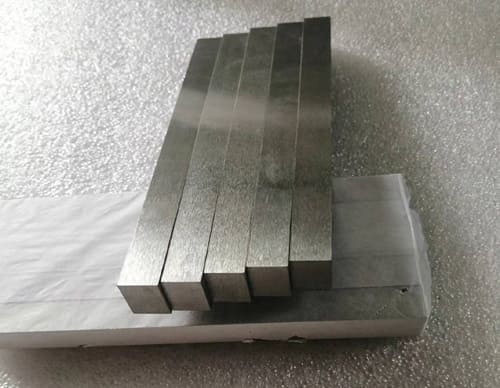

Zirconium Rod Zirconium Bar

Zirconium Rod/Bar Material Composition

| Material | Chemical Composition (%) | |||||

| Zr+Hf | Hf | Nb | Sn | Fe | Cr | |

| Zr 702 | ~99.5 | 1-2.5 | — | — | <0.05 | <0.05 |

| Zr 704 | ~97.5 | <4.5 | — | 1-2 | 0.1-0.2 | 0.1-0.2 |

| Zr 705 | ~95.5 | <4.5 | 2-3 | 1-2 | <0.05 | <0.01 |

Zirconium Rod/Bar Mechanical Properties

| Material | Temper | Rm(≥)/MPa | Rp0.2(Pa) | A50mm(≥)/% |

| Zirconium 702 (UNS R60702) | annealed | 379 | 207 | 16 |

| Zirconium 704 (UNS R60704) | annealed | 413 | 241 | 14 |

| Zirconium 705 (UNS R60705) | annealed | 552 | 379 | 16 |

Zirconium Rod/Bar Features

- Excellent corrosion resistance

- High melting point

- Low-neutron absorption cross-section

- Excellent radiation resistance

Zirconium Rod/Bar Production Process

- Raw Material: Select high-purity zirconium powder.

- Powder Metallurgy: Mix with binder and compact into a green billet.

- Sintering: High-temperature sintering to remove the binder and increase density.

- Drawing: Draw the rod to achieve the desired size and finish.

- Heat Treatment: Anneal to relieve stress and enhance properties.

- Surface Treatment: Clean and polish the surface.

- Cutting & Customization: Cut or customize according to requirements.

Zirconium Rod/Bar Processing Method

- Sintering

- Forging

- Rotary Forging

- Rolling

- Polishing

Zirconium Rod/Bar Applications

- Nuclear Energy Industry: zirconium rod material can be used to produce reactor control rods.

- Chemical Industry: zirconium rods can be used to make corrosion-resistant pipes and equipment, especially in highly corrosive environments, such as sulfuric acid, hydrogen fluoride, and other acidic media.

- Aerospace: zirconium rods are often used for components in high-temperature environments, such as high-temperature parts of engines.

- Electronics Industry: zirconium has good electrical conductivity and corrosion resistance, so it is used in the electronics industry as electrode materials in some special environments and to manufacture some special electronic components.

Zirconium Rod/Bar Packaging

The Zirconium Rod/Bar is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Zirconium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Rod/Bars Products

Heeger Metal supplies refractory metal and alloy rods/bars made from high-performance materials like tungsten, molybdenum, and tantalum. These rods offer excellent strength, high melting points, and resistance to wear and corrosion, making them ideal for aerospace, electronics, and high-temperature applications. Available in various sizes, they can be customized to meet specific needs.

Other Zirconium/Hafnium Products

Heeger Metal provides a wide selection of zirconium and hafnium products, celebrated for their excellent corrosion resistance, high temperature stability, and remarkable strength in extreme environments. These qualities make them ideal for critical applications in industries such as aerospace, nuclear power, and chemical processing. Our high-purity zirconium and hafnium materials ensure superior performance and durability, even in the most demanding conditions.