Zirconium Powder

Zirconium Powder

Material: Pure Zr, Zr702, Zr704, Zr705

Purity: 95%-99.95%

Zirconium Powder is made from high-purity zirconium metal or alloys in a wide range of purity and particle sizes, widely used in alloy additives, powder metallurgy, nuclear industry, fireworks manufacturing, and other fields. As a leading supplier and manufacturer of premium zirconium products, Heeger Materials leverages advanced technology to deliver high-purity zirconium and zirconium alloy powders for wide ranges of applications.

Or email us at max@heegermaterials.com.This product is currently unavailable. Please check other products. Thank you.

Zirconium Powder Data Sheet

| Reference: | HMZZ1154 |

| Material: | Pure Zr, Zr702, Zr704, Zr705 |

| Purity: | 95%-99.95% |

| Particle Size: | Customized |

Zirconium Powder

Zirconium (Zr) is a light gray metal with a density of 6.49 g/cm3, a high melting point of 1850 ℃, and a boiling point of 4377 ℃. Zirconium Powder is a gray powder with a metallic luster. It is flammable in the air and emits white light when burning, forming zirconium oxide. It is insoluble in water, soluble in hot concentrated acid, hydrofluoric acid, aqua regia, and concentrated sulfuric acid. Due to its excellent gas absorption and high-temperature resistance properties, zirconium powder is well applied and studied in zirconium products, thermal spraying fields, and powder metallurgy processes.

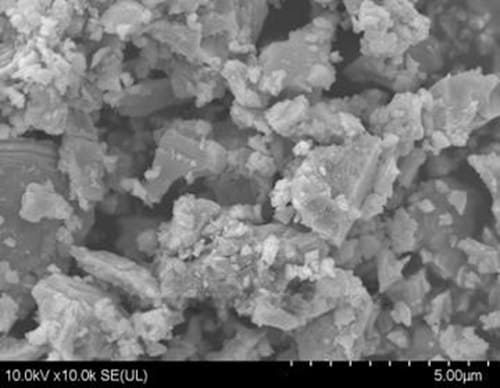

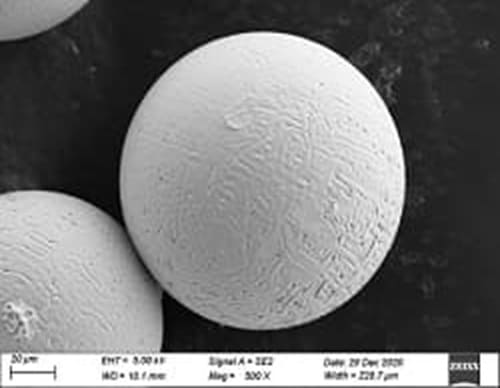

Zirconium (Zr) Powder Irregular Zirconium Powder_SEM Zirconium Spherical Powder_SEM

Zirconium Powder Specifications

| Product | Purity | Grade | Particle Size | Shape |

| Zirconium and Zirconium Alloy Powder | 95% – 99.95% | Coarse Powder | 150 -500 μm | Irregular Powder Spherical Powder |

| 95% – 99.95% | Intermediate Powder | 44 – 150 μm | ||

| 95% – 99.95% | Fine Powder | 10 – 44 μm | ||

| 95% – 99.95% | Ultrafine Powder | 0.5 – 10 μm | ||

| 95% – 99.95% | Superfine Powder | 0 – 0.5 μm | ||

| 95% – 99.95% | Nanopowder | 1 – 100 nm |

Zirconium Powder Applications

- Nuclear Industry: Zirconium powder is used to manufacture fuel cladding and other structural materials for nuclear reactors.

- Aerospace: Zirconium powder is commonly used to manufacture structural materials for aerospace vehicles.

- Powder Metallurgy: zirconium powder can be used to manufacture high-performance alloys and composite materials to enhance the strength and wear resistance of materials.

- Fireworks: Zirconium powder can be used as a burning agent in fireworks, emitting bright white light when burning.

- Electro-Vacuum Industry: Zirconium powder can be used to make electro-vacuum devices in the suction agent, to maintain the vacuum environment.

Zirconium Powder Packaging

The Zirconium Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Zirconium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Powder Products

Heeger Metal offers a comprehensive range of metal powder products, including spherical powders, and nano powders. Our high-quality metal powders are ideal for applications in 3D printing, powder metallurgy, electronics, and advanced manufacturing. These powders provide excellent consistency, flowability, and particle size distribution, ensuring superior performance in various industrial processes. Whether you need custom metal powders or standard alloy powders, our products meet the highest quality standards for precision and reliability.

Other Zirconium/Hafnium Products

Heeger Metal provides a wide selection of zirconium and hafnium products, celebrated for their excellent corrosion resistance, high temperature stability, and remarkable strength in extreme environments. These qualities make them ideal for critical applications in industries such as aerospace, nuclear power, and chemical processing. Our high-purity zirconium and hafnium materials ensure superior performance and durability, even in the most demanding conditions.