Hafnium Wire

Hafnium Wire

Material: Hf+Zr≥99.95%, Zr≤2.5%

Standard: AWS A5.24/A5.24M, ASME SFA-5.24/SFA-5.24M

Hafnium Wire is drawn from hafnium metal, with excellent corrosion resistance, high-temperature tolerance, and high strength. It is widely applied in aerospace, nuclear energy, electronics, and high-temperature alloys. As a leading supplier and manufacturer of premium hafnium products, Heeger Materials leverages advanced technology to deliver high-purity hafnium and hafium alloys wires for wide ranges of applications.

Or email us at sales@heegermaterials.com.This product is currently unavailable. Please check other products. Thank you.

Hafnium Wire Data Sheet

| Reference: | HMHF1499 |

| Material: | Hf+Zr≥99.95%, Zr≤2.5% |

| Standard: | AWS A5.24/A5.24M, ASME SFA-5.24/SFA-5.24M |

| Purity: | 99%-99.95% |

| Dimension: | Diameter: 0.5-6 mm, or customized Length: TBD (To Be Determined) |

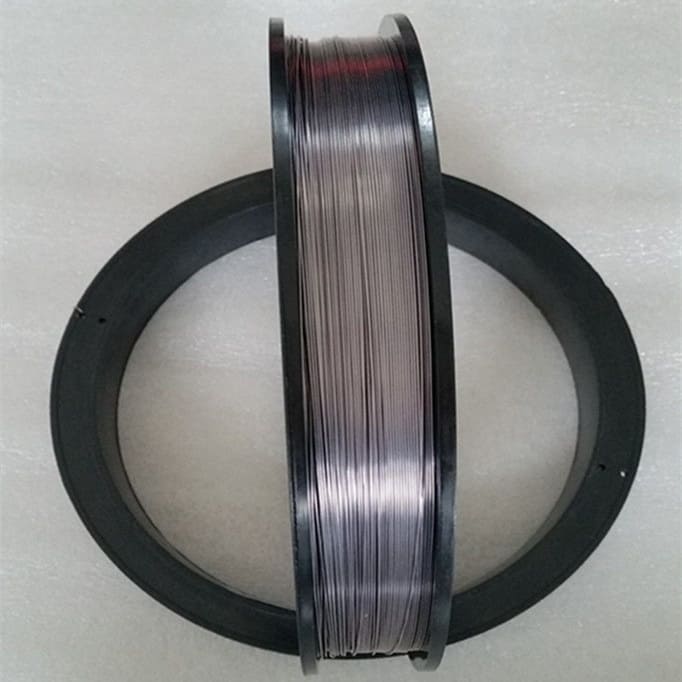

| Product Form: | Straight, Coil, or Spooled |

| Temper: | Annealed and Unannealed |

Hafnium Wire

Hafnium (Hf) is a lustrous, silver-gray transition metal with a very high melting point (2230°C) and high density (13.31 g/cm3). Hafnium Wire is drawn from high-purity hafnium metal or its alloy, exhibiting excellent performance in high-temperature environments. It is commonly used as a plasma emitter for plasma-cutting machine electrodes. HM can supply high-quality hafnium and hafnium alloy wires of various shapes and sizes.

Hafnium (Hf) Wire-Coil Hafnium (Hf) Wire-Spool

Hafnium Wire Material Chemical Composition

| Chemical Composition (%) | |||||||||

| Hf+Zr | Zr | Si | Mo | Al | Ni | C | H | O | N |

| ≥99.95 | ≤1 | ≤0.001 | ≤0.001 | ≤0.0005 | ≤0.005 | ≤0.003 | ≤0.001 | ≤0.015 | ≤0.003 |

| Cu | Sn | Fe | Ti | Mn | Cr | Sb | Pb | Mg | Nb |

| ≤0.0005 | ≤0.0005 | ≤0.01 | ≤0.001 | ≤0.0005 | ≤0.001 | ≤0.0005 | ≤0.0005 | ≤0.0005 | ≤0.0005 |

Hafnium Wire Specifications

| Purity | Hf+Zr≥99.9%, Zr≤2.5% or Customized | ||

| Dimensions | Single Wire | Coil Wire | According to customer’s requirements. |

| 1.07, 1.2, 1.5 2.0mm dia. × 1000mm (Straight Wire) | 1.07, 1.2, 1.5, 1.6, 2.0 mm dia. x L φ0.1~3mm × Lmm (Customized) | ||

| Shape | It can be straight, in coils, or on spools. | ||

Hafnium Wire Production Process

- Melting and Casting: Hafnium sponge is melted and cast using an electron beam furnace or purified through iodization, followed by melting and casting to produce high-purity hafnium ingots.

- Forging and Rolling: The hafnium ingots are heated and then subjected to forging and rolling at high temperatures to form preliminary rods.

- Spin Forging: Depending on the bar’s diameter, the appropriate spinning machine and die are selected. Multiple spin forging processes are performed to achieve the desired dimensions.

- Drawing: After intermediate annealing, the bar’s surface is evenly coated with graphite emulsion, which is then dried before being processed through a drawing die.

- Heat Treatment: The drawn hafnium wire undergoes heat treatment to relieve processing stresses and enhance its material properties.

- Finishing & Inspection: Steps such as cutting, polishing, cleaning, and strict quality inspection ensure that the product meets specifications.

Hafnium Wire Applications

- Plasma Cutting Electrodes: Hafnium wire is commonly used as the electrode material for plasma cutting machines.

- Nuclear Industry: Hafnium wire is widely used in nuclear reactors’ control rods and shielding materials.

- Electronics Industry: Hafnium wire is a lead material in electronic devices, especially at high temperatures and frequencies.

- Alloy Additives: Hafnium wires are used as additives to improve the alloys’ mechanical properties and corrosion resistance.

Hafnium Wire Packaging

The Hafnium Wire is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Hafnium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Wire Products

We specialize in providing high-quality custom wire products, including straight wires, coiled wires, and thermal spray wires. We offer various materials such as tungsten, molybdenum, nickel alloys, and more, ensuring precision and performance for diverse industrial applications. Whether you need wires for manufacturing, coating, or specialized coatings like thermal spraying, our custom wire solutions are designed to meet your specific requirements with superior strength and reliability.

Useful Information

Other Zirconium/Hafnium Products

Heeger Metal provides a wide selection of zirconium and hafnium products, celebrated for their excellent corrosion resistance, high temperature stability, and remarkable strength in extreme environments. These qualities make them ideal for critical applications in industries such as aerospace, nuclear power, and chemical processing. Our high-purity zirconium and hafnium materials ensure superior performance and durability, even in the most demanding conditions.