Nitinol Wire

Nitinol Wire

Material: NiTi, NiTiFe, NiTiCu, NiTiCo, NiTiCuCr, etc.

Standard: ASTM F2063-12

Nitinol Wire is made from nickel and titanium in a near 1:1 ratio. It has a unique shape memory effect and superelasticity, widely used in medical devices, aerospace, robotics, and consumer electronics. As a leading supplier and manufacturer of premium nitinol alloys products, Heeger Metal leverages advanced technology to deliver high-quality nitinol wires for various applications.

Or email us at sales@heegermaterials.com.Nitinol Wire Data Sheet

| Material: | NiTi, NiTiFe, NiTiCu, NiTiCo, NiTiCuCr, etc. |

| Standard: | ASTM F2063-12 |

| Dimensions: | Diameter: minimum 0.05 mm Width: ~100 mm Length: customized Other dimensions can be customized according to specific requirements |

| Available Wire Type: | Round wire, flat wire, or customized |

| Available Product Shape: | Straight, Coils, or On spools |

| Surface State: | Black oxidized state Light oxidation state (from golden to brown) Clean state Bright state Super bright state Abrasive |

| Af Temperature: | -10 ℃ to 120 ℃ |

What Is The Nitinol Alloy?

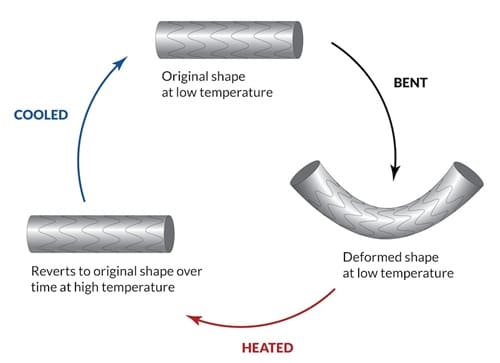

Nitinol, also called NiTi shape memory alloy, is a metal alloy composed of nickel and titanium, typically in a near 1:1 ratio. It has a unique shape-memory effect and superelasticity, allowing it to return to a preset shape when heated or recover its original form after significant deformation. It offers an expansion rate of over 20%, a fatigue life of 107 cycles, damping properties ten times greater than regular springs, and superior corrosion resistance compared to stainless steel. Due to its excellent biocompatibility, corrosion resistance, and mechanical properties, Nitinol alloy is widely used in medical devices (e.g., stents and orthodontic wires), aerospace, industrial manufacturing, and consumer products.

Nitinol Wire

Nitinol Wire is known for its unique shape memory effect and superelasticity. At room temperature, Nitinol wire can undergo significant deformation and fully recover its original shape, while heating it to a specific temperature triggers its ability to “remember” and return to a pre-set form. It also has excellent biocompatibility, corrosion resistance, and high fatigue life, making it widely applied in medical devices. HM can offer customized solutions for wire type, diameter, and surface state according to specific requirements.

Nitinol Straight Wire Nitinol Flat Wire Nitinol Wire Coil Nitinol Wire Spool

Nitinol Wire Material Chemical Composition

| Chemical Composition (wt%) | ||||

| Fe | Ni | Cr | Cu | Nb |

| ≤0.05 | 54.5-57.0 | ≤0.01 | ≤0.01 | ≤0.025 |

| C | Ti | Co | N+O | H |

| ≤0.05 | Balanced | ≤0.05 | ≤0.050 | ≤0.005 |

Nitinol Wire Material Code

| NiTi Wire Material Code | A | B | C | D | E | F | G | H |

| Active Af/℃ | 70±10 | 30±10 | 25±5 | 17±7 | 10±10 | 5±10 | -20±10 | -30±15 |

Nitinol Wire Key Properties And Applications

| NiTi Wire Material Code | Straightening Hyperelastic State | Typical Medical Applications | ||||

| Tensile Strength (σb/MPa) | Elongation (δ/%) | Upper Plateau Stress (σload /MPa) | Residual Deformation (%) | Active (Af/℃) | ||

| D | ≥1300 | ≥10 | ≥480 | <0.5 | 10±7 | Guide wires, braided brackets, dental root canal files, arch wires, birth control rings, sutures, etc. |

| C | ≥1150 | ≥10 | ≥440 | <0.5 | 17±7 | |

| S | ≥1000 | ≥10 | ≥400 | <0.5 | 25±5 | |

Nitinol Wire Diameters And Tolerances

| Diameter (mm) | Tolerance (mm) |

| 0.025-0.05 | ±0.002 |

| 0.05-0.08 | ±0.003 |

| 0.08-0.15 | ±0.004 |

| 0.15-0.26 | ±0.005 |

| 0.26-0.35 | ±0.007 |

| 0.35-1.00 | ±0.010 |

| 1.00-2.00 | ±0.015 |

| 2.00-4.00 | ±0.020 |

Nitinol Wire Advantages

- Shape memory

- Superelesticity

- Biocompatibility

- Corrosion resistance

- High damping capacity

- Adjustable transformation temperature

- High fatigue life

- Lightweight

- Good shock absorption properties

Nitinol Wire Surface Finish

- Black: The surface is “as swaged” or “as drawn”, retaining a coating of processing lubricants and oxides.

- Cleaned: The surface is chemically cleaned to remove all lubricants and oxides.

- Ground: The surface is centerless to remove all coating and achieve precise dimensions control.

Nitinol Wire Applications

- Medical Field: Nitinol wire is commonly used in orthodontics, vascular stents, guide wires in minimally invasive surgeries, and orthopedic implants, due to its good elasticity, shape memory properties, and biocompatibility.

- Industry and Machinery: Leveraging the sensitivity of Nitinol wire to temperature changes, it can be used to make thermal switches or automatic adjustment valves. Additionally, it serves as a vibration-damping material in mechanical systems to absorb vibration energy.

- Consumer Products: The superelasticity of Nitinol wire makes eyeglass temples highly durable, resistant to deformation, and provides a comfortable fit.

Nitinol Wire Packaging

Nitinol Wire products are carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Wire Products

We specialize in providing high-quality custom wire products, including straight wires, coiled wires, and thermal spray wires. We offer various materials such as tungsten, molybdenum, nickel alloys, and more, ensuring precision and performance for diverse industrial applications. Whether you need wires for manufacturing, coating, or specialized coatings like thermal spraying, our custom wire solutions are designed to meet your specific requirements with superior strength and reliability.

Useful Information

Other Nitinol Products

Heeger Metal offers a comprehensive range of titanium alloy products, including Nitinol, in various forms such as powders and finished parts, with customization options available. Known for its unique shape-memory properties, exceptional strength, corrosion resistance, and biocompatibility, Nitinol is ideal for use in medical devices, aerospace, robotics, and other advanced engineering applications.