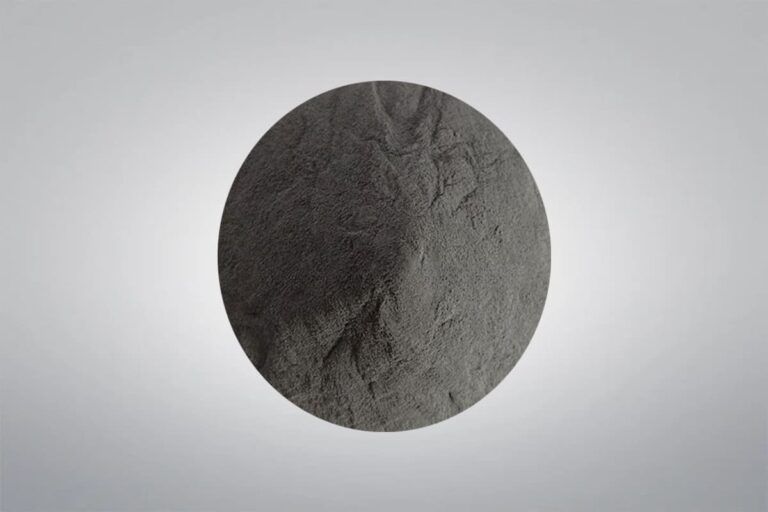

Tantalum Niobium Alloy Powder

Tantalum Niobium Alloy Powder

Material: Ta-3Nb, Ta-20Nb, Ta-30Nb, Ta-40Nb, or customized

Particle Size: -500 mesh, -300 mesh, -200 mesh, -100 mesh, or customized

Tantalum Niobium Alloy Powder is a high-performance alloy powder widely used in aerospace, nuclear energy, electronic components, chemical industries, and medical devices. As a leading supplier and manufacturer of premium tantalum niobium alloy products, Heeger Metal leverages advanced technology to deliver high-quality tantalum niobium alloy powder for various applications.

Or email us at sales@heegermaterials.com.Tantalum Niobium Alloy Powder Data Sheet

| Purity: | >99.9% |

| Material: | Ta-3Nb, Ta-20Nb, Ta-30Nb, Ta-40Nb, or customized |

| Particle Size: | -500 mesh, -300 mesh, -200 mesh, -100 mesh, or customized |

| Morphology: | Irregular or Spherical |

Tantalum Niobium Alloy Powder

Tantalum Niobium Alloy Powder is primarily composed of tantalum and niobium elements, offering exceptional high-temperature and corrosion resistance. It can be used to manufacture high-temperature alloys, electronic capacitors, reactor materials, and additive manufacturing components, making it particularly suitable for high-demand applications in extreme environmental conditions. To meet diverse application requirements, we have also developed a comprehensive range of high-performance powder products, including high-purity tantalum powder, low-oxygen tantalum powder (oxygen content as low as 200ppm), low-oxygen niobium powder (oxygen content as low as 400ppm), C103 niobium alloy powder, Tantalum Tungsten Alloy Powder, etc. HM can offer high-quality tantalum niobium alloy powder in various particle sizes, customized to meet the specific requirements of multiple applications.

Tantalum Niobium Alloy Powder Chemical Composition

| Description | Mainly Content (%) | Impurities (≤%) | ||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | O | C | H | N | |

| TaNb3 | Reminder | 2.5~3.5 | 0.005 | 0.005 | 0.004 | 0.005 | 0.005 | 0.004 | 0.012 | 0.005 | 0.0015 | 0.005 |

| TaNb20 | Reminder | 17.0~23 | 0.005 | 0.005 | 0.004 | 0.005 | 0.005 | 0.004 | 0.012 | 0.005 | 0.0015 | 0.005 |

| TaNb30 | Reminder | 27.0~33 | 0.005 | 0.004 | 0.003 | 0.004 | 0.004 | 0.003 | 0.012 | 0.004 | 0.0015 | 0.004 |

| TaNb40 | Reminder | 37.0~43 | 0.005 | 0.004 | 0.003 | 0.004 | 0.004 | 0.003 | 0.012 | 0.004 | 0.001 | |

Tantalum Niobium Alloy Powder Appliable Process

- Metal Injection Molding (MIM)

- Additive Manufacturing (AM)

- Hot Isostatic Pressing (HIP)

- Thermal Spray Coating

Tantalum And Tantalum Alloy Grades

- UNS R05400, unalloyed tantalum, powder-metallurgy consolidation.

- UNS R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- UNS R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace vacuum-arc melt, or both.

- UNS R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Niobium Alloy Powder Applications

- Aerospace: Used to manufacture high-performance parts, such as engine nozzles and combustion chambers, requiring high-temperature and corrosion resistance.

- Nuclear Energy: Used in nuclear reactor structural materials, heat exchangers, and protective layers for nuclear fuel, with radiation resistance and corrosion resistance.

- Electronic Components: Used in high-performance capacitors, wires, and contact materials, suitable for high-frequency and high-temperature environments.

- Chemical Industry: Used to make chemical reactors, pipes, and other corrosion-resistant equipment, adapting to extreme corrosive environments.

- Medical Devices: Used in implants and surgical tools, with good biocompatibility.

- Additive Manufacturing: Used in 3D printing to produce complex metal parts, widely used in aerospace and nuclear energy fields.

- High-Temperature Alloys: Used in the production of high-temperature alloys, suitable for extreme environments with high oxidation and corrosion resistance.

Tantalum Niobium Alloy Powder Packaging

Tantalum Niobium Alloy Powder products are carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Powder Products

Heeger Metal offers a comprehensive range of metal powder products, including spherical powders, and nano powders. Our high-quality metal powders are ideal for applications in 3D printing, powder metallurgy, electronics, and advanced manufacturing. These powders provide excellent consistency, flowability, and particle size distribution, ensuring superior performance in various industrial processes. Whether you need custom metal powders or standard alloy powders, our products meet the highest quality standards for precision and reliability.

Other Tantalum Products

Heeger Metal offers a comprehensive range of tantalum and tantalum alloy products, renowned for their outstanding corrosion resistance, high melting point, and stability in harsh environments. These characteristics make them ideal for demanding applications in the aerospace, electronics, and chemical processing industries. Our high-purity tantalum materials deliver exceptional performance and reliability in challenging conditions.

Other Niobium Products

Heeger Metal offers a comprehensive range of niobium and niobium alloy products, including powders and finished parts, with customization options available. Known for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are ideal for aerospace, electronics, and chemical processing applications. Our high-purity niobium ensures reliable performance and durability in the most demanding environments.