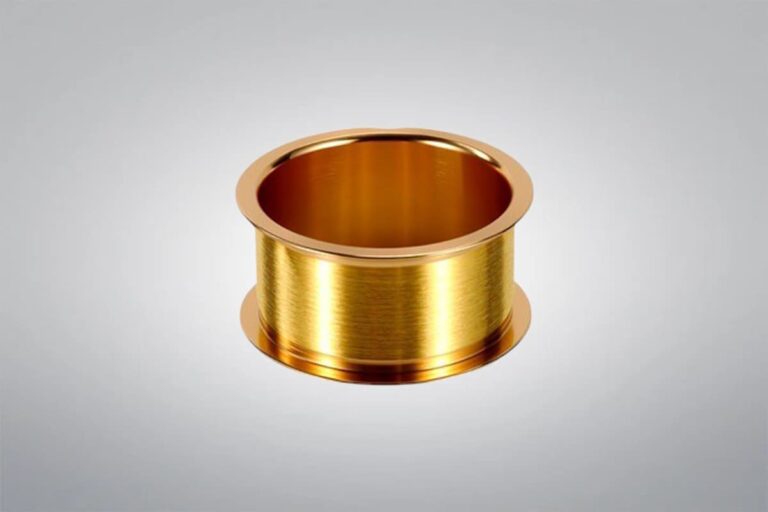

Platinum Rhodium Crucible

Platinum Rhodium Crucible

Material: PtRh5, PtRh10, PtRh15, PtRh20, PtRh30, or customized

Platinum Rhodium Crucible is a high-performance container made from a high-quality blend of platinum and rhodium. It is ideal for high-temperature chemical reactions, metal melting, and material testing. It is available in various shapes and sizes to accommodate diverse laboratory and industrial needs. As a leading supplier and manufacturer of premium platinum products, Heeger Metal leverages advanced technology to deliver high-quality platinum rhodium crucibles for various applications.

Or email us at sales@heegermaterials.com.Platinum Rhodium Crucible Data Sheet

| Reference Code: | HMPL2702 |

| Material: | PtRh5, PtRh10, PtRh15, PtRh20, PtRh30, or customized |

| Density: | 19.97 g/cm3 |

| Dimension: | Customized |

| Precision: | ±0.001 mm |

| Temper: | Annealed or Unannealed |

Platinum Rhodium Crucible Description

Platinum Rhodium Alloy combines the best properties of both metals, offering exceptional strength, durability, and stability even under extreme conditions. Platinum Rhodium crucible offers excellent thermal conductivity, corrosion resistance, and minimal contamination, ensuring the highest purity during processing. With superior mechanical properties, platinum rhodium crucibles are widely applied in metallurgy, chemical analysis, aerospace, and research laboratories. Heeger Metal can supply high-quality platinum rhodium crucibles in various sizes and shapes, and customized designs for multiple industrial and research applications.

Platinum Rhodium Crucible Specifications

| Capacity (ml) | Upper Diameter (mm) | Lower Diameter (mm) | Height (mm) | Thickness (mm) | Weight (g) |

| 5 | 19 | 12 | 25 | 0.22 | 7 |

| 8 | 22 | 13 | 25 | 0.22 | 10 |

| 10 | 22 | 14 | 28 | 0.26 | 12 |

| 12 | 26 | 16 | 29 | 0.27 | 13 |

| 15 | 28 | 17 | 35 | 0.28 | 15 |

| 20 | 33 | 18 | 35 | 0.28 | 20 |

| 25 | 35 | 20 | 37 | 0.30 | 25 |

| 30 | 37 | 22 | 40 | 0.34 | 30 |

| 35 | 38 | 23 | 40 | 0.34 | 35 |

| 40 | 40 | 25 | 45 | 0.34 | 40 |

| 50 | 45 | 27 | 50 | 0.34 | 50 |

| 60 | 49 | 29 | 50 | 0.34 | 60 |

| 75 | 53 | 32 | 56 | 0.38 | 75 |

| 80 | 54 | 33 | 58 | 0.38 | 80 |

| 100 | 58 | 35 | 60 | 0.38 | 100 |

Platinum Rhodium Crucible Forming Methods

- Spinning: Shaping platinum-rhodium alloy sheets into crucibles using a rotating mold, ideal for thin-walled crucibles with high precision.

- Stamping: Pressing platinum-rhodium alloy sheets into crucible shapes with molds, suitable for mass-producing standard shapes.

- Welding: Cutting and rolling platinum-rhodium sheets, then welding them into crucibles, used for custom or large crucibles.

- Powder Metallurgy: Pressing and sintering platinum-rhodium alloy powder, suitable for complex shapes or high-density crucibles.

- Electrical Discharge Machining (EDM): Fine machining of pre-formed crucibles, ideal for high-precision or specialized structures.

Platinum Rhodium Crucible Advantages

- Smooth surface

- Uniform wall thickness

- Single-piece forming of the sheet material, with no seams or welds

- High precision

Platinum Rhodium Crucible Applications

- Materials Science: For high-temperature melting and crystal growth experiments, such as producing single-crystal silicon, sapphire, or oxide crystals.

- Chemical Analysis: In laboratories for high-temperature decomposition, sample melting, or ashing analysis, such as for ores or ceramics.

- Glass Industry: For melting specialty or high-purity glass materials.

- Metallurgical Industry: For melting and refining precious metals or high-melting-point alloys.

- Scientific Research: As reaction vessels in high-temperature chemical reactions or thermodynamic studies.

Platinum Rhodium Crucible Packaging

Platinum Rhodium Crucible is carefully placed in wooden cases or cartons with additional soft materials to support and prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Platinum Rhodium Alloy Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Crucible Products

Heeger Metal specializes in high-quality customized metal crucibles and alloy crucibles, designed to withstand extreme temperatures for melting and casting applications. Made from durable materials, our crucibles ensure excellent performance in industries such as metallurgy and material science. For more details or custom solutions, feel free to contact us.