Gold Bonding Wire

Gold Bonding Wire

Purity: ≥99.95%, or customized

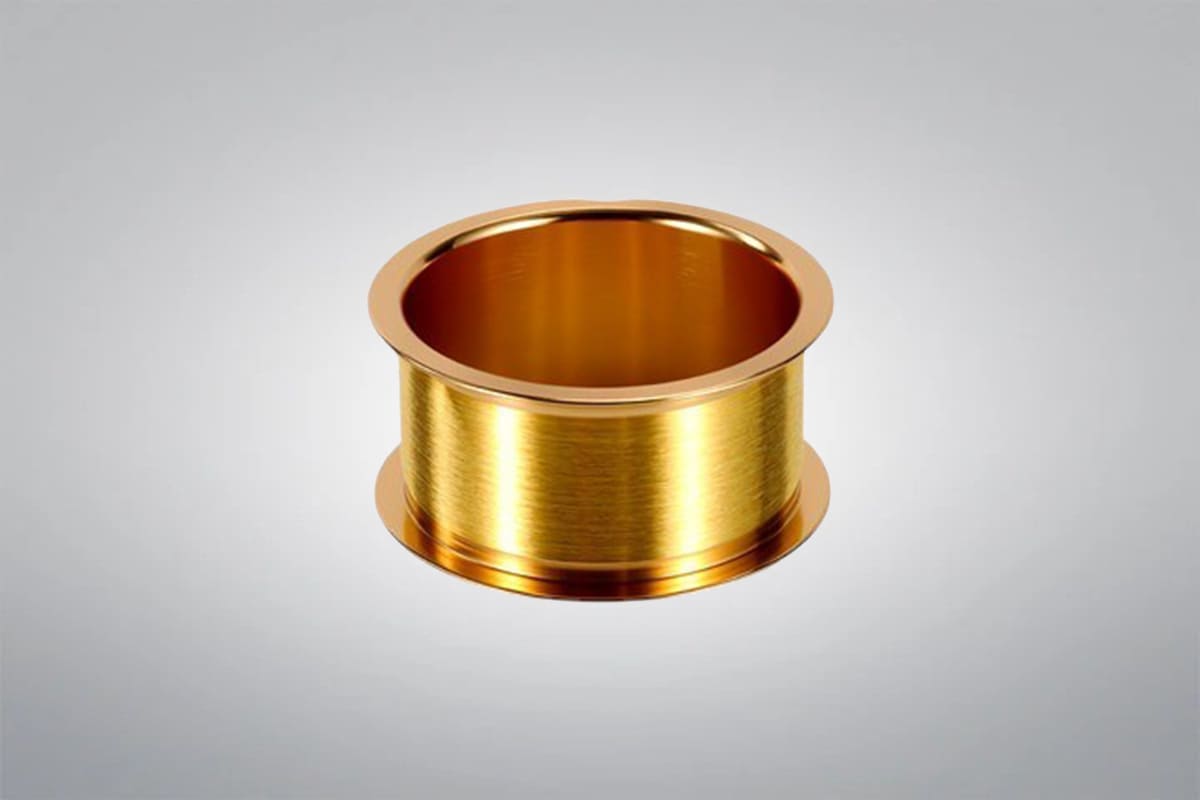

Gold Bonding Wire is a high-performance wire used in the semiconductor industry to create electrical connections between microchips and their packaging. As a leading supplier and manufacturer of premium gold products, Heeger Metal leverages advanced technology to deliver high-quality gold bondingwires for various applications.

Or email us at sales@heegermaterials.com.Gold Bonding Wire Data Sheet

| Reference Code: | HMGO2723 |

| CAS: | 7440-57-5 |

| Purity: | ≥99.95%, or customized |

| Density: | 19.283 g/cm3 |

| Melting Point: | 1064℃ |

| Boiling Point: | 2970℃ |

| Temper: | Annealed or Unannealed |

Gold Bonding Wire Description

Gold (Au) has excellent conductivity, chemical stability, and malleability, making it invaluable for various applications. Gold Bonding Wire is made of high-purity gold metal with a maximum purity of 99.999% (5N). It has excellent electrical conductivity, corrosion resistance, and malleability, making it mainly used in wire bonding applications for integrated circuits (ICs), and other microelectronic components. The gold bonding wire ensures a strong and reliable connection. Heeger Metal can supply high-quality gold bonding wires in various diameters and lengths to suit industrial and research applications, ensuring optimal performance and cost-effectiveness.

Gold Bonding Wire Chemical Composition

| Element | Content (wt%) | CAS No. |

| Gold (Au) | 99.99% | 7440-57-5 |

| Silver (Ag) | 0.0015% | 7440-22-4 |

| Iron (Fe) | 0.0010% | 7439-89-6 |

| Lead (Pb) | 0.0005% | 7439-92-1 |

| Magnesium (Mg) | 0.0005% | 7439-95-4 |

| Copper (Cu) | 0.0015% | 7440-50-8 |

| Silicon (Si) | ≤0.0010% | 7440-21-3 |

| Other | ≤0.0040% | — |

Gold Bonding Wire Specifications

| Diameter (μm) | Elongation (%) | Weight per 500 meters (g) | Breaking Load (cN) | ||

| G1 | G2 | G3 | |||

| 18±1 | 2.0-5.0 | 2.457 | >2.5 | >4.0 | >5.0 |

| 20±1 | 2.0-6.0 | 3.033 | >4.0 | >5.0 | >6.0 |

| 23±1 | 2.0-7.0 | 4.011 | >5.5 | >7.0 | >8.0 |

| 25±1 | 2.0-8.0 | 4.739 | >7.5 | >9.0 | >10.0 |

| 28±1 | 2.0-8.0 | 5.945 | >9.0 | >12.0 | >13.0 |

| 30±1 | 3.0-8.0 | 6.825 | >11.0 | >13.0 | >15.0 |

| 32±1 | 3.0-8.0 | 7.765 | >12.0 | >15.0 | >16.0 |

| 33±1 | 3.0-8.0 | 8.258 | >13.0 | >16.0 | >18.0 |

| 35±1 | 3.0-10.0 | 9.289 | >15.0 | >18.0 | >20.0 |

| 38±1 | 3.0-10.0 | 10.950 | >18.0 | >21.0 | >22.0 |

| 40±1 | 3.0-10.0 | 12.133 | >20.0 | >24.0 | >26.0 |

| 45±1 | 3.0-12.0 | 15.356 | >25.0 | >28.0 | >30.0 |

| 50±2 | 3.0-12.0 | 18.958 | >30.0 | >34.0 | >36.0 |

| 60±3 | 7.0-14.0 | 27.299 | >45.0 | >50.0 | >52.0 |

| 70±3 | 7.0-14.0 | 37.157 | >55.0 | >60.0 | >63.0 |

| 75±3 | 7.0-14.0 | 42.655 | >65.0 | >65.0 | >68.0 |

Gold Bonding Wire Advantages

- Extreme bond reliability

- Wide processing window

- Low-impact ball and wedge bonding

- Superior looping performance

- High-tensile test performance

- Excellent corrosion-resistance

- Ultra-fine pitch

- A variety of spool sizes

Gold Bonding Wire Applications

- Semiconductor Packaging: Gold bonding wire is used to connect the integrated circuit (IC) to the lead frame in semiconductor devices. It ensures high-performance and long-lasting electrical connections.

- LED Packaging: In LED technology, gold wire is used to bond the LED chip to the frame, ensuring a stable and reliable electrical connection.

- Microelectronics: Gold bonding wire is essential for wire bonding in microelectronics, providing strong and conductive connections for small-scale electronic components.

- Automotive Electronics: Gold wire is used in automotive electronics for its durability and resistance to extreme conditions, ensuring long-term reliability in critical systems like sensors and control units.

- Medical Devices: Gold bonding wire is used in medical devices, including pacemakers and other implants, due to its biocompatibility and reliability over long periods.

- Aerospace: In aerospace applications, gold wire is used for its robustness and ability to perform in high-stress and high-temperature environments.

- Consumer Electronics: Gold bonding wire is also used in consumer electronics such as smartphones, tablets, and wearables, where reliable and long-lasting connections are crucial.

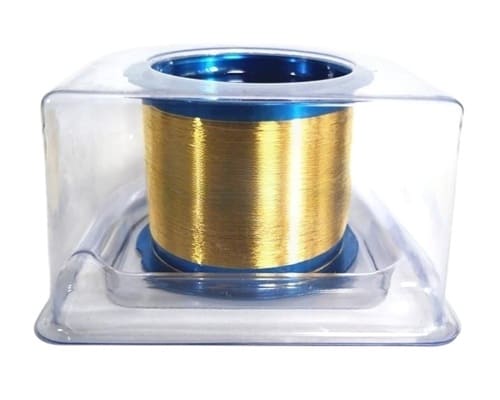

Gold Bonding Wire Packaging

Gold Bonding Wire is carefully placed in wooden cases or cartons with additional soft materials to support and prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Gold Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Wire Products

We specialize in providing high-quality custom wire products, including straight wires, coiled wires, and thermal spray wires. We offer various materials such as tungsten, molybdenum, nickel alloys, and more, ensuring precision and performance for diverse industrial applications. Whether you need wires for manufacturing, coating, or specialized coatings like thermal spraying, our custom wire solutions are designed to meet your specific requirements with superior strength and reliability.