Silver Plate/Sheet/Disc

Silver Plate/Sheet/Disc

Purity: ≥99.95%, or customized

Silver Plate/Sheet/Disc is made from high-purity silver metal through precise techniques. It offers excellent electrical conductivity, corrosion resistance, and thermal conductivity, available in various sizes and thicknesses. As a leading supplier and manufacturer of premium silver products, Heeger Metal leverages advanced technology to deliver high-quality silver plates, sheets, and discs for various applications.

Or email us at max@heegermaterials.com.Silver Plate/Sheet/Disc Data Sheet

| Reference Code: | HMSI2713 |

| CAS: | 7440-22-4 |

| Purity: | ≥99.95%, or customized |

| Density: | 10.503 g/cm3 |

| Melting Point: | 961.78℃ |

| Boiling Point: | 2162℃ |

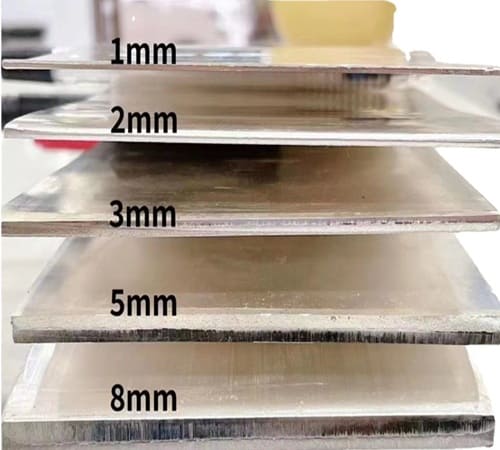

| Thickness: | 0.1-10 mm, or customized |

| Delivery State: | Hard, Semi-hard, or Soft states as specific requirements |

| Temper: | Annealed or Unannealed |

Silver Plate/Sheet/Disc Description

Silver (Ag) is a precious metal known for its highest electrical conductivity, thermal conductivity, and reflectivity of any metal. Additionally, it also has excellent resistance to corrosion and oxidation. Silver Plate/Sheet/Disc is made of high-purity silver metal, widely applied in electronics, electrical components, and solar panels. Heeger Metal can supply high-quality silver plates, sheets, and discs in various specifications and customized solutions to suit industrial and research applications, ensuring optimal performance and cost-effectiveness.

Silver Plate/Sheet/Disc Manufacturing Processes

- Melting: The refined silver is then melted in a furnace at high temperatures, typically around 960°C (1760°F). This allows the silver to reach a liquid state.

- Casting: Once melted, the liquid silver is cast into molds to form bars or billets. These billets are the starting material for producing silver plates, sheets, or discs.

- Rolling: The silver billets are heated and passed through rolling mills, where they are gradually reduced in thickness and shaped into thin sheets or plates. The rolling process is done in stages, each reducing the thickness incrementally.

- Annealing: To prevent the silver from becoming brittle due to work hardening during the rolling process, the silver is periodically heated in an annealing furnace. This softens the metal and restores its ductility.

- Cutting and Forming: Once the silver plate or sheet reaches the desired thickness, it can be cut into discs or other shapes using specialized cutting tools. The discs are typically stamped or punched out from larger sheets.

- Polishing and Surface Treatment: After the silver plate, sheet, or disc is shaped, it is polished to achieve a smooth, shiny surface. This can be done using abrasive materials or through electro-polishing techniques.

- Quality Control: The final products undergo rigorous quality checks for defects, such as imperfections in thickness, surface quality, and overall appearance. They are also tested for purity to ensure they meet industry standards.

Silver Plate/Sheet/Disc Applications

- Electronics: Silver plates, sheets, and discs are widely used in the production of electrical contacts, connectors, and conductors due to their excellent electrical conductivity.

- Reflective Coatings: Silver’s high reflectivity makes it ideal for use in optical mirrors and reflective coatings for instruments like telescopes and lasers.

- Solar Panels: Silver is a key material in photovoltaic cells, and silver plates or sheets are used in the manufacturing of solar panels for efficient energy conversion.

- Medical Applications: Due to its biocompatibility, silver is used in medical devices, such as implants, wound dressings, and coatings for surgical instruments to prevent bacterial growth.

- Thermal Conductivity: Silver plates and sheets are utilized in applications requiring high thermal conductivity, such as heat exchangers and cooling systems in electronics and industrial processes.

Silver Plate/Sheet/Disc Packaging

Silver Plate/Sheet/Disc is carefully placed in wooden cases or cartons with additional soft materials to support and prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Silver Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Plate/Sheet/Disc Products

Heeger Metal offers a wide range of custom plate, sheet, and disc products, available in materials like tungsten, molybdenum, titanium, and nickel alloys. Our precision-engineered products are ideal for various industrial applications, including aerospace, electronics, and energy. Whether you need flat plates, thin sheets, or precision-cut discs, we provide tailored solutions with exceptional strength, durability, and high-performance characteristics to meet your specific requirements.