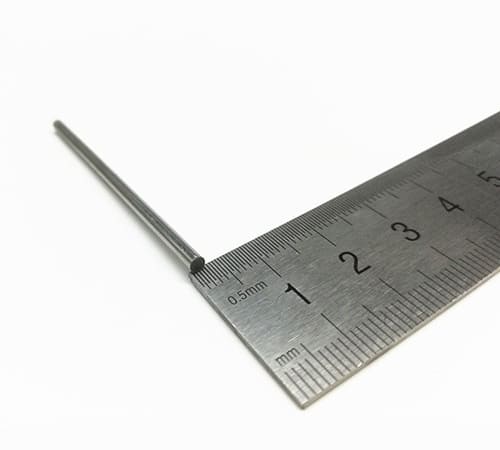

Iridium Rod/Bar

Iridium Rod/Bar

Purity: >99.9%

Iridium Rod/Bar is a high-performance material made from a high-purity iridium up to 99.95%, offering excellent high-temperature strength and corrosion resistance. As a leading supplier and manufacturer of premium iridium products, Heeger Metal leverages advanced technology to deliver high-quality iridium rods and bars for various applications.

Or email us at sales@heegermaterials.com.Iridium Rod/Bar Data Sheet

| CAS: | 7439-88-5 |

| Purity: | >99.9% |

| Density: | 22.4 g/cm3 |

| Melting Point: | 2410℃ |

| Boiling Point: | 4130℃ |

| Temper: | Annealed or Unannealed |

Iridium Rod/Bar Description

Iridium (Ir) is a dense, corrosion-resistant, and highly durable metal. Iridium Rod/Bar is a high-performance material made from high-purity iridium. It is particularly valued for its superior high-temperature resistance, corrosion resistance, and conductivity, making it ideal for chemical processing, high-temperature furnaces, and critical electronic components. Heeger Metal can supply high-quality iridium rods and bars with various diameters, lengths, surface finishes, and customized solutions to suit industrial and research applications, ensuring optimal performance and cost-effectiveness.

Iridium Rod/Bar Chemical Composition

| Impurities(≤%) | ||||||||

| Pt | Ru | Rh | Pd | Au | Ag | Cu | Fe | Ni |

| 0.02 | 0.02 | 0.02 | 0.01 | 0.01 | 0.005 | 0.005 | 0.005 | 0.005 |

| Al | Pb | Mn | Mg | Sn | Si | Zn | Ca | |

| 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | |

Iridium Rod/Bar Tolerances

| Diameter | ≤10mm | ±10% |

|---|---|---|

| Diameter | >10mm | ±5% |

Iridium Rod/Bar Advantages

- Excellent corrosion resistance

- High temperature stability

- Superior durability

- Excellent conductivity

- Biocompatibility

- High density

- Strong mechanical properties

Iridium Rod/Bar Applications

- Electrochemical Applications: Iridium rods and bars are widely used as electrodes in electrochemical processes, including water splitting, hydrogen production, and fuel cells. Their resistance to corrosion and excellent conductivity make them ideal for these applications.

- High-Temperature Applications: Iridium rods and bars can withstand extremely high temperatures, making them suitable for use in high-temperature environments like aerospace, jet engines, and industrial furnaces.

- Catalysis: Iridium is an essential material in catalytic systems, including those used in petroleum refining, chemical processing, and automotive catalytic converters. Iridium rods and bars are often used as catalysts or catalyst supports due to their stability and efficiency.

- Medical Devices: Due to their biocompatibility, iridium rods and bars are used in medical devices like pacemakers, neurostimulators, and implants. Their durability and non-reactivity in the human body make them ideal for long-term medical use.

- Electronics: Iridium rods and bars are used in high-performance electrical contacts and components, where high conductivity and durability are critical. These materials are often used in aerospace and military applications.

- Precision Instruments: Iridium rods are also used in the manufacturing of precision instruments, such as thermocouples and measuring devices, that require materials with high stability and resistance to extreme conditions.

Iridium Rod/Bar Packaging

Iridium Rod/Bar is carefully placed in wooden cases or cartons with additional soft materials to support and prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Iridium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Rod/Bars Products

Heeger Metal supplies refractory metal and alloy rods/bars made from high-performance materials like tungsten, molybdenum, and tantalum. These rods offer excellent strength, high melting points, and resistance to wear and corrosion, making them ideal for aerospace, electronics, and high-temperature applications. Available in various sizes, they can be customized to meet specific needs.