Aluminum-Based Master Alloy

Aluminum-Based Master Alloy

Material: AlSc, AlCa, AlCo, AlZn, AlZr, AlY, AlYb, AlGd, AlEr, AlTiB, AlMgSi, etc.

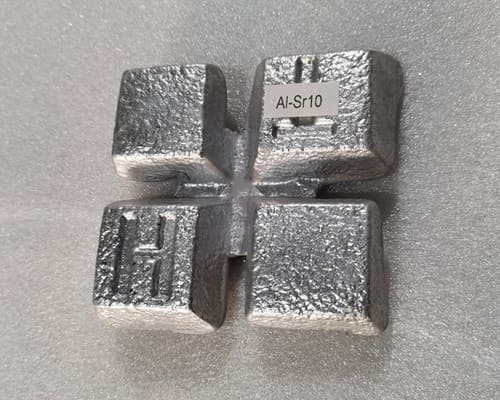

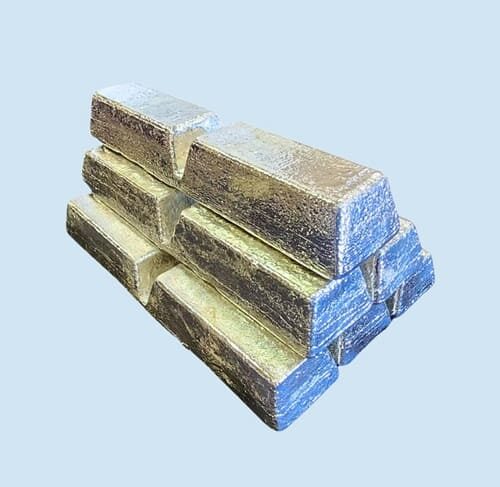

Shape: Waffle Ingot/Cut-Waffle Ingot/Notch-Bar Ingot/Shot

Aluminum-Based Master Alloy is a high-performance alloy made from aluminum in precise proportions with other metal elements (e.g., Ti, B, Sr, Cr, rare earth elements, etc.). We can adjust the composition ratio according to specific requirements. As a leading supplier and manufacturer of premium master alloy products, Heeger Materials leverages advanced technology to deliver high-quality aluminum-based master alloys for various applications.

Or email us at sales@heegermaterials.com.Aluminum-Based Master Alloy Data Sheet

| Material: | AlSc, AlCa, AlCo, AlZn, AlZr, AlSi, AlMo, AlNb, AlY, AlYb, AlGd, AlEr, AlNd, AlLaCe, AlTiB, AlMgSi, etc., or Customized |

| Purity: | >99% |

| Dimensions: | Customized |

| Shape: | Waffle Ingot, Cut-Waffle Ingot, Notch-Bar Ingot, Shot, etc. |

What Is A Mater Alloy?

Master alloy is a pre-alloyed material consisting of two or more metal elements, usually with one metal as the base and one or more high-content alloying elements. It is mainly used as an additive to adjust and optimize the composition and properties of the target alloy. HM can provide high-quality magnesium-based master alloys, aluminum-based master alloys, copper-based master alloys, nickel-based master alloys, cobalt-based master alloys, iron-based master alloys, etc.

Aluminum-Based Master Alloy

Aluminum-Based Master Alloy is made from aluminum and other metal elements (e.g., Ti, B, Sr, Cr, rare earth elements, etc.) through advanced melting and casting processes, ensuring high-quality products with high purity, uniform organization, and stable chemical composition. These master alloy products have excellent strength, lightweight characteristics, and good corrosion resistance, significantly improving the aluminum alloys’ mechanical properties, refining the grain structure, and enhancing the corrosion resistance and processing performance. HM can offer customized solutions for adjusting the composition ratio to meet specific requirements.

Aluminum-Based Master Alloy Features

- Composition Uniformity: Precise melting process ensures uniform distribution of alloying elements and avoids compositional segregation.

- Multifunctionality: The composition of the master alloy can be adjusted according to the requirements to meet the performance requirements of different alloys.

- Various Forms: We can provide many forms according to the customer’s requirements, such as waffle ingot, cut waffle ingot, notch-bar, shot, etc.

Aluminum-Based Master Alloy Advanced Production Line

HM has advanced production lines with cutting-edge technology and precision engineering, ensuring consistent quality and performance in every batch. We can offer customization capabilities to tailor the composition, grain structure, and mechanical properties to meet every specific application demand. Our expert team will deliver a professional solution if you need enhanced strength, better corrosion resistance, or improved high-temperature performance.

- Raw Materials Preparation: Select suitable metal raw materials according to the requirements, wash, dry, and crush them to ensure no impurities and reach the required particle size.

- Accurate Dosing: Accurately weigh and pre-mix the raw materials according to the target alloy requirements.

- Melting: Melting is carried out using equipment such as induction furnaces, electric arc furnaces, or resistance furnaces, with the addition of protective gases (e.g. argon) to prevent oxidization if necessary. Ensure uniform distribution of alloy components through mechanical or electromagnetic stirring.

- Casting: The melted liquid alloy is poured into molds and cooled to form ingots.

- Heat Treatment: Heat treatment of ingots eliminates compositional segregation and internal stresses and improves organization uniformity.

- Processing and Molding: Cutting or crushing the ingot into the desired shape and size.

Aluminum-Based Master Alloy Products List

| Reference | Master Alloy Name | Molecular formula | Master Alloy Ratio | Shape |

| HMMA1355 | Aluminium Scandium Master Alloy | AlSc | Al-0.02Sc, Customized |  Waffle-ingot  Notch-bar  Cut-waffle Ingot  Rod Rod Ingot Ingot Shot Shot |

| HMMA1481 | Aluminum Calcium Master | AlCa | Al-65Ca, Al-75Ca, Al-85Ca, Customized | |

| HMMA1482 | Aluminum Cobalt Master Alloy | AlCo | Al-65Co, Al-75Co, Al-85Co, Customized | |

| HMMA1510 | Aluminium Antimony Master Alloy | AlSb | Al-8Sb, Al-10Sb, Al-15Sb, Customized | |

| HMMA1511 | Aluminium Beryllium Master Alloy | AlBe | Al-2.5Be, Al-5Be, Customized | |

| HMMA1512 | Aluminium Bismuth Master Alloy | AlBi | Al-0.1Bi, Customized | |

| HMMA1513 | Aluminium Boron Master Alloy | AlB | Al-3B, Al-4B, Al-5B, Al-6B, Al-8B, Al-10B, Customized | |

| HMMA1514 | Aluminium Cerium Master Alloy | AlCe | Al-0.1Ce, Customized | |

| HMMA1515 | Aluminium Chromium Master Alloy | AlCr | Al-5Cr, Al-10Cr, Al-20Cr, Al-80Cr, Customized | |

| HMMA1516 | Aluminium Copper Master Alloy | AlCu | Al-33Cu, Al-50Cr, Al-80Cr, Customized | |

| HMMA1517 | Aluminium Copper Phosphorus Master Alloy | AlCuP | Al-Cu-P, Customized | |

| HMMA1518 | Aluminium Dysprosium Master Alloy | AlDy | Al-Dy, Customized | |

| HMMA1519 | Aluminium Erbium Master Alloy | AlEr | Al-Er, Customized | |

| HMMA1520 | Aluminium Gadolinium Master Alloy | AlGd | Al-Gd, Customized | |

| HMMA1521 | Aluminium Gallium Master Alloy | AlGa | Al-Ga, Customized | |

| HMMA1522 | Aluminium Germanium Master Alloy | AlGe | Al-Ge, Customized | |

| HMMA1523 | Aluminium Hafnium Master Alloy | AlHf | Al-Hf, Customized | |

| HMMA1524 | Aluminium Indium Master Alloy | AlIn | Al-5In, Al-10In, Customized | |

| HMMA1525 | Aluminium Iron Master Alloy | AlFe | Al-10Fe, Al-20Fe, Al-25Fe, Al-30Fe, Al-45Fe, Al-80Fe, Customized | |

| HMMA1526 | Aluminium Lanthanum Master Alloy | AlLa | Al-0.1La, Customized | |

| HMMA1527 | Aluminium Lithium Master Alloy | AlLi | Al-2Li, Al-5Li, Customized | |

| HMMA1528 | Aluminium Magnesium Master Alloy | AlMg | Al-20Mg, Al-25Mg, Al-50Mg, Al-65Mg, Al-75Mg, Customized | |

| HMMA1529 | Aluminium Magnesium Boron Master Alloy | AlMgB | Al-Mg-B, Customized | |

| HMMA1530 | Aluminium Magnesium Silicon Master Alloy | AlMgSi | Al-Mg-Si, Customized | |

| HMMA1531 | Aluminium Manganese Master Alloy | AlMn | Al-10Mn, Al-15Mn, Al-20Mn, Al-25Mn, Al-25Mn, Al-30Mn, Al-60Mn, Al-80Mn, Customized | |

| HMMA1532 | Aluminium Nickel Master Alloy | AlNi | Al-20Ni, Al-50Ni, Customized | |

| HMMA1533 | Aluminium Niobium Master Alloy | AlNb | Al-50Nb, Al-60Nb, Al-65Nb, Al-70Nb, Al-80Nb, Customized | |

| HMMA1534 | Aluminium Molybdenum Master Alloy | AlMo | Al-50Mo, Al-60Mo, Al-70Mo, Al-80Mo, Customized | |

| HMMA1536 | Aluminium Praseodymium Master Alloy | AlPr | Al-Pr, Customized | |

| HMMA1537 | Aluminium Silicon Master Alloy | AlSi | Al-20Si, Al-25Si, Al-30Si, Al-50Si, Customized | |

| HMMA1538 | Aluminium Silicon Calcium Master Alloy | AlSiCa | Al-Si-Ca, Customized | |

| HMMA1539 | Aluminium Silicon Iron Master Alloy | AlSiFe | Al-Si-Fe, Customized | |

| HMMA1540 | Aluminium Silicon Strontium Master Alloy | AlSiSr | Al-Si-Sr, Customized | |

| HMMA1541 | Aluminium Silver Master Alloy | AlAg | Al-0.1Ag, Customized | |

| HMMA1542 | Aluminium Strontium Master Alloy | AlSr | Al-3.5Sr, Al-5Sr, Al-10Sr, Al-15Sr, Customized | |

| HMMA1543 | Aluminium Strontium Titanium Boron Master Alloy | AlSrTiB | Al-Sr-Ti-B, Customized | |

| HMMA1544 | Aluminium Tantalum Master Alloy | AlTa | Al-70Ta, Customized | |

| HMMA1545 | Aluminium Titanium Master Alloy | AlTi | Al-5Ti, Al-6Ti, Al-10Ti, Al-80Ti, Customized | |

| HMMA1546 | Aluminium Titanium Boron Master Alloy | AlTiB | Al-5Ti-1B, Al-3Ti-1B, Al-5Ti-0.2B, Customized | |

| HMMA1547 | Aluminium Titanium Carbon Master Alloy | AlTiC | Al-3Ti-0.15C, Al-3Ti-0.2C, Customized | |

| HMMA1548 | Aluminium Tungsten Master Alloy | AlW | Al-W, Customized | |

| HMMA1549 | Aluminium Ytterbium Master Alloy | AlYb | Al-Yb, Customized | |

| HMMA1550 | Aluminium Yttrium Master Alloy | AlY | Al-0.1Y, Customized | |

| HMMA1551 | Aluminium Vanadium Master Alloy | AlV | Al-5V, Al-10V, Customized | |

| HMMA1552 | Aluminium Zinc Master Alloy | AlZn | Al-10Zn, Al-20Zn, Al-30Zn, Customized | |

| HMMA1553 | Aluminium Zirconium Master Alloy | AlZr | Al-5Zr, Al-6Zr, Al-10Zr, Al-15Zr, Customized | |

| HMMA1946 | Aluminum Lanthanum Cerium Master Alloy | AlLaCe | Al-La-Ce, Customized | |

| HMMA1945 | Aluminum Neodymium Master Alloy | AlNd | Al-10Nd, Al-20Nd, Al-50Nd, Customized |

Aluminum-Based Master Alloy Applications

- Aluminum Alloy Production: Aluminum-based master alloys are commonly used to regulate elemental content during the melting process of aluminum alloys.

- Aluminum Alloy Casting: Aluminum-based master alloys can improve the fluidity, castability, and surface quality of aluminum alloys.

- Aluminum Alloy Tempering: By adding specific elements, Aluminum Master Alloys can help improve the mechanical properties of aluminum alloys, such as increasing strength, hardness, and corrosion resistance.

- Welding Materials: Certain aluminum-based master alloys can be used as welding materials to provide the required composition to improve the performance of welded joints.

- Electronics and Automotive: Aluminum-based alloys are commonly used to produce lightweight aluminum alloys for electronics and automotive parts.

Aluminum-Based Master Alloy Packaging

The Aluminum-based Master Alloy products are carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.