High-Entropy Alloy Custom Parts – HEA

High-Entropy Alloy Custom Parts | HEA

Material: FeMnCoCr, TiZrHfVNb, TiNbMoTaW, TiVAlCrZr, CoCrFeNiMn, WMoTaZr, Al4TiVFeSc, or Customized.

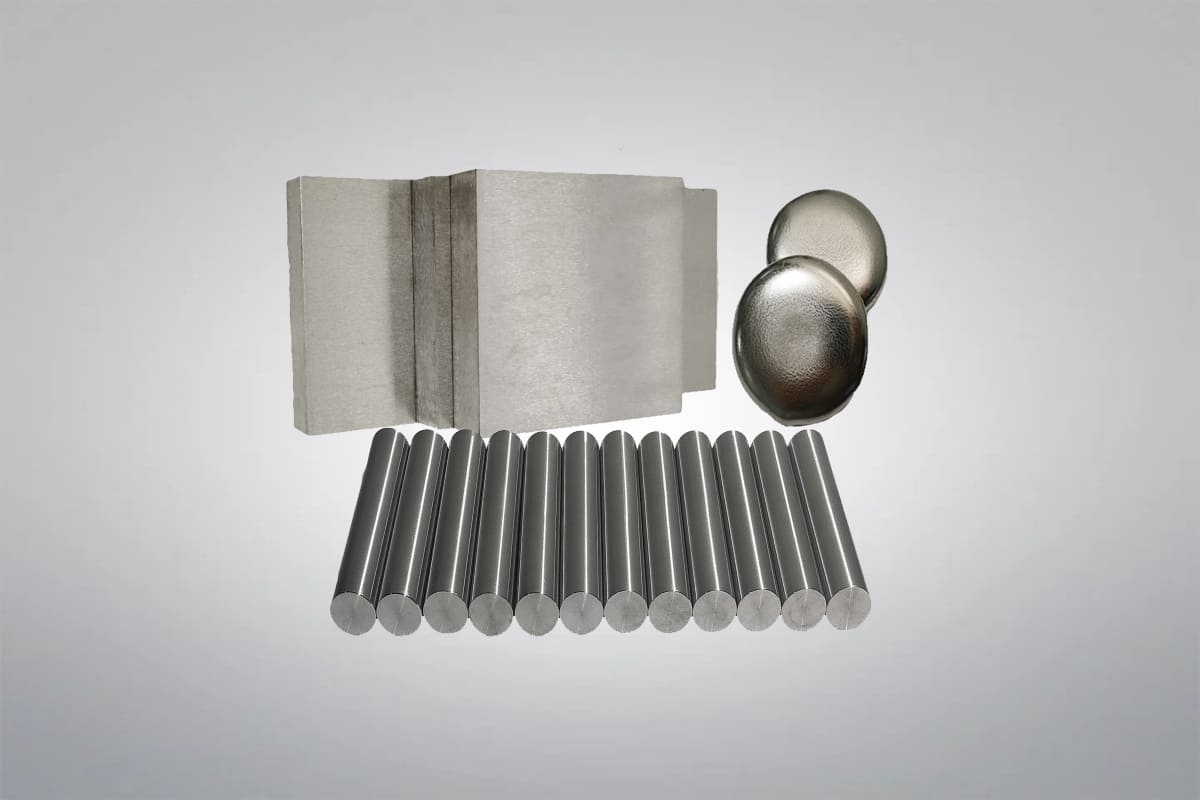

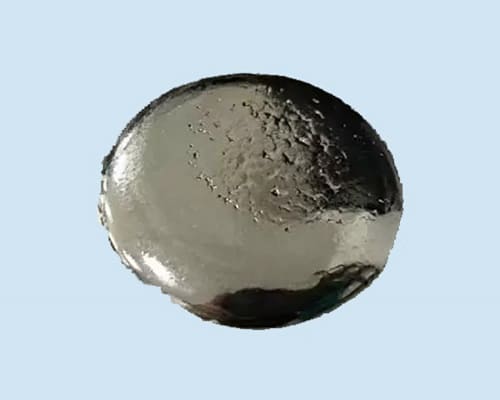

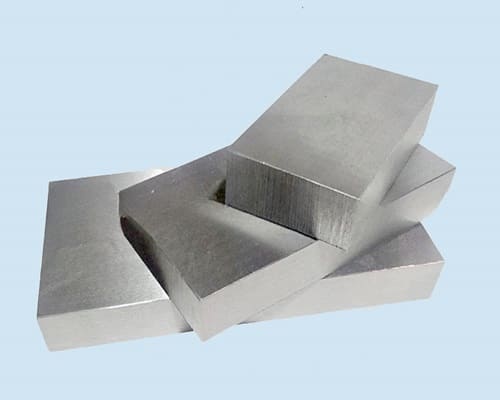

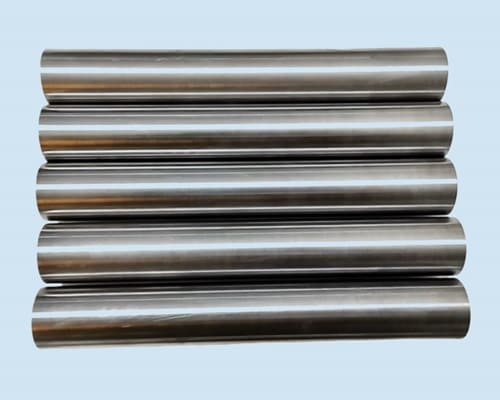

Shape: Ingot/Plate/BMG (Bulk Metallic Glass)/Tensile Specimen/Custom Part

High-entropy Alloy Custom Parts are high-performance alloy material designed to meet specific customer needs. We can adjust the composition and ratio according to specific requirements and offer various shapes including ingot, plate, rod, BMG, tensile specimen, and custom parts. As a leading supplier and manufacturer of premium high-entropy alloy products, Heeger Materials leverages advanced technology to deliver high-quality high-entropy alloy custom parts for various applications.

Or email us at sales@heegermaterials.com.High-Entropy Alloy Custom Parts Data Sheet

| Material: | FeMnCoCr, TiZrHfVNb, TiNbMoTaW, TiVAlCrZr, CoCrFeNiMn, WMoTaZr, Al4TiVFeSc, or Customized. |

| Production Method: | Vacuum Arc Melting (VAM), Vacuum Induction Melting (VIM), Levitation/Suspension Melting, Plasma Melting, Laser Melting, Resistance Heating Melting, etc. |

| Shape: | Ingot, Plate, BMG (Bulk Metallic Glass), Tensile Specimen, Custom Parts, etc. |

What Is A High-Entropy Alloy?

High-entropy alloys (HEAs) are a new type of material typically composed of five or more metals in equal or near-equal proportions, exhibiting exceptional properties. The four core effects of HEAs work together to distinguish them from traditional alloys:

- High-Entropy Effect: Due to the near-equimolar mixing of multiple elements, the configurational entropy of high-entropy alloys is significantly increased, typically ≥1.5R (R is the gas constant). This high-entropy effect promotes the stability of a single solid-solution phase (such as FCC or BCC structures) while suppressing the formation of complex compounds or intermetallics. It does so by lowering the Gibbs free energy of the system (ΔG = ΔH – TΔS), enhancing the thermodynamic stability of the solid-solution phase at high temperatures.

- Lattice Distortion Effect: The differences in atomic size and chemical properties among the constituent elements in HEAs cause significant lattice distortion. This distortion enhances solid-solution strengthening, boosting the alloy’s strength and hardness, while also slowing atomic diffusion rates, which improves creep resistance and thermal stability.

- Sluggish Diffusion Effect: The complexity arising from the multi-element composition results in slower atomic diffusion rates in HEAs compared to conventional alloys. This sluggish diffusion effect delays phase separation, grain growth, and microstructural evolution, thereby enhancing stability at elevated temperatures and extending service life.

- Cocktail Effect: The synergistic interaction of multiple elements produces unexpected combinations of properties, much like blending ingredients in a cocktail to create a unique flavor. This effect allows HEAs to integrate the strengths of individual elements (e.g., strength, ductility, corrosion resistance), often surpassing the performance limits of single-element systems and exhibiting a wide range of functional characteristics.

High-Entropy Alloy Custom Parts

High-entropy Alloy Custom Parts are made of 5 or more equal or custom proportions of metal elements through vacuum melting, induction melting, electron beam melting, levitation/suspension Melting, etc. The metal composition and ratio can be adjusted according to the specific requirements. The various shapes of ingots, plates, rods, BMGs, tensile specimens, and custom parts are available for multiple applications. In addition to high-entropy alloys, we also offer customized services for medium-entropy alloys (MEAs) and low-entropy alloys (LEAs).

HEA BMG HEA Ingot HEA Ingot HEA Plate HEA Rod HEA Custom Parts

HEA VS. MEA VS. LEA

| Property | High-entropy Alloys (HEAs) | Medium-entropy Alloys (MEAs) | Low-entropy Alloys (LEAs) |

| Number of Elements | 5 or more | 3 to 4 | 1 to 2 |

| Entropy Value | High (≥1.5R) | Medium (1R~1.5R) | Low (<1R) |

| Microstructure | Simple solid solution | Simple solid solution | May form complex phases |

| Performance | High strength, high-temperature resistance, corrosion resistance | Performance between HEAs and LEAs | Relatively simple performance |

| Typical Applications | Aerospace, energy, and chemical industries | Structural materials, wear-resistant coatings | Construction, automotive, machinery manufacturing |

High-Entropy Alloy Custom Parts Features

- High Strength and Hardness: Lattice distortion and solid solution strengthening effects significantly enhance mechanical properties.

- Excellent High-temperature Resistance: The slow diffusion effect makes it stable at high temperatures.

- Good Corrosion Resistance: The dense oxide layer formed by multiple elements enhances the corrosion resistance.

- Outstanding Wear Resistance: High hardness and strength enable excellent performance in friction and abrasion environments.

High-Entropy Alloy Custom Parts Products List

| Reference | High-entropy Alloy Name | Production Method | Shape |

| HM2523 | FeMnCoCr High-entropy Alloy | Vacuum Arc Melting (VAM) Vacuum Induction Melting (VIM) Levitation Melting Plasma Melting Laser Melting Resistance Heating Melting Mechanical Alloying Powder Metallurgy |  HEA Ingot  HEA BMG  HEA Ingot  HEA Ingot  HEA Plate  HEA Rod  HEA Tensile Specimen  HEA Tensile Specimen  HEA Tensile Specimen |

| HM2522 | TiZrHfVNb High-entropy Alloy | ||

| HM2521 | TiNbMoTaW High-entropy Alloy | ||

| HM2520 | TiVAlCrZr High-entropy Alloy | ||

| HM2519 | CoCrFeNiV High-entropy Alloy | ||

| HM2518 | AlZrNbMo High-entropy Alloy | ||

| HM2517 | ZrMoCrNb High-entropy Alloy | ||

| HM2516 | TaHfZrTi High-entropy Alloy | ||

| HM2515 | CoCrFeNiMo High-entropy Alloy | ||

| HM2514 | CoCrNiAlTi High-entropy Alloy | ||

| HM2513 | TiZrHfVMo High-entropy Alloy | ||

| HM2512 | TiZrVNbMo High-entropy Alloy | ||

| HM2511 | ZrVMoHfNb High-entropy Alloy | ||

| HM2510 | WMoTaZr High-entropy Alloy | ||

| HM2509 | CuAlTiVW High-entropy Alloy | ||

| HM2508 | NbMoTaWAl High-entropy Alloy | ||

| HM2507 | TiZrVTa High-entropy Alloy | ||

| HM2506 | 0.2FeCoNi(AlSi)0.2 High-entropy Alloy | ||

| HM2505 | Al1Mo0.5Nb1Ta0.5Ti1Zr1 High-entropy Alloy | ||

| HM2504 | Al4TiVFeSc High-entropy Alloy | ||

| HM2503 | Al4TiVFeGe High-entropy Alloy | ||

| HM2502 | Al4TiVFeCr High-entropy Alloy | ||

| HM2501 | TiZrVTaMo High-entropy Alloy | ||

| HM2500 | CoCrFeNiTi High-entropy Alloy | ||

| HM2499 | FeCrCoAlTi High-entropy Alloy | ||

| HM2498 | TiZrHfVTa High-entropy Alloy | ||

| HM2497 | AlCrFeCuNi High-entropy Alloy | ||

| HM2496 | 30Ti20Nb20Ta20Zr10Mo High-entropy Alloy | ||

| HM2495 | MoNbTi High-entropy Alloy | ||

| HM2494 | AlCoCrFeNi2.1 High-entropy Alloy | ||

| HM2493 | AlCoCrNi High-entropy Alloy | ||

| HM2492 | AlxCoCrFeNi High-entropy Alloy | ||

| HM2491 | CoCrFeNi High-entropy Alloy | ||

| HM2490 | CoCrFeNiCu High-entropy Alloy | ||

| HM2489 | CoCrFeNiMn High-entropy Alloy | ||

| HM2486 | Fe50Mn30Co10Cr10 High-entropy Alloy | ||

| HM2483 | TiNbTaZrMo High-entropy Alloy | ||

| HM2482 | TiZrTaNb High-entropy Alloy | ||

| HM2481 | WMoTaNb High-entropy Alloy | ||

| HM2480 | WMoTaNbV High-entropy Alloy | ||

| HM2479 | WMoTiTaZrHf High-entropy Alloy | ||

| HM2478 | TiZrHfNbMo High-entropy Alloy | ||

| HM2477 | TiZrTaNbHf High-entropy Alloy |

High-entropy Alloy Custom Parts Melting Method

| Melting Method | Principle | Advantages | Applicable Scenarios |

| Vacuum Arc Melting (VAM) | Uses an electric arc to melt metals in a vacuum or inert atmosphere | High purity, simple operation, suitable for high-melting-point elements | Lab research, small-batch production |

| Vacuum Induction Melting (VIM) | Electromagnetic induction heats metal in a crucible under vacuum | Ideal for large-scale production, good compositional uniformity | Industrial production, medium-to-large scale |

| Levitation/Suspension Melting | Electromagnetic field suspends and heats metal to melting point | High purity, no crucible contamination | High-purity research, reactive metals |

| Resistance Heating Melting | Melts raw materials in a resistance furnace at high temperature | Simple equipment, low cost | Small-scale experiments, simple alloys |

| Plasma Melting | Uses plasma to generate ultra-high temperatures to melt metals | High heating efficiency, suits refractory metals | High-melting-point alloys, specialized research |

| Laser Melting | Laser locally heats and melts raw materials | High precision, applicable to additive manufacturing | Thin films, 3D printing, microstructure studies |

| Mechanical Alloying + Melting | Ball-mills powders for mixing, followed by melting | Suitable for difficult-to-melt or uneven compositions | Complex alloys, fundamental research |

High-entropy Alloy Custom Parts Applications

- Aerospace: For high-temperature components such as turbine blades and engine parts.

- Energy: For nuclear reactor materials and high-temperature fuel cells.

- Chemical: For corrosion-resistant equipment and piping.

- Medical Devices: For biocompatible implant materials.

- Defense Industry: Used for armor materials and structural components in extreme environments.

High-Entropy Alloy Custom Parts Packaging

The High-entropy Alloy Custom Parts products are carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.