Nitinol Powder

Nitinol Powder

Material: NiTi, NiTiFe, NiTiCu, NiTiCo, NiTiCuCr, NiTiNb, etc.

Particle Size: 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, customized

Nitinol Powder is a high-performance shape-memory alloy material made from nickel and titanium in a near 1:1 ratio. It is widely used in additive manufacturing (3D printing), metal injection molding (MIM), and coating technology. As a leading supplier and manufacturer of premium nitinol alloys products, Heeger Metal leverages advanced technology to deliver high-quality nitinol powder for various applications.

Or email us at sales@heegermaterials.com.Nitinol Powder Data Sheet

| Material: | NiTi, NiTiFe, NiTiCu, NiTiCo, NiTiCuCr, NiTiNb, etc. |

| Particle Size: | 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, customized |

| Process: | Water Atomization (WA) Gas Atomization (GA) Plasma Rotating Electrode Process (PREP) Radio Frequency Plasma Spheroidization |

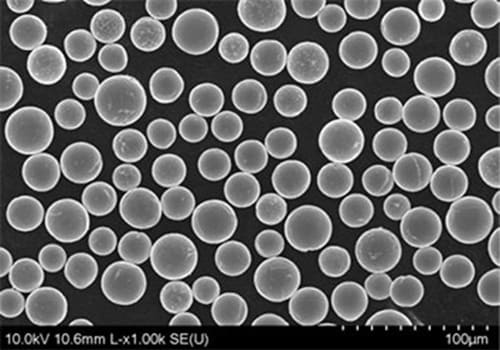

| Morphology: | Irregular or Spherical |

What Is The Nitinol Alloy?

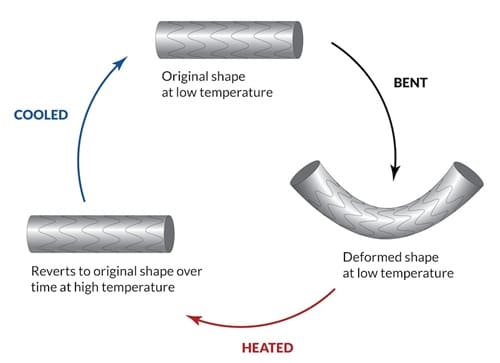

Nitinol, also called NiTi shape memory alloy, is a metal alloy composed of nickel and titanium, typically in a near 1:1 ratio. It has a unique shape-memory effect and superelasticity, allowing it to return to a preset shape when heated or recover its original form after significant deformation. It offers an expansion rate of over 20%, a fatigue life of 107 cycles, damping properties ten times greater than regular springs, and superior corrosion resistance compared to stainless steel. Due to its excellent biocompatibility, corrosion resistance, and mechanical properties, Nitinol alloy is widely used in medical devices (e.g., stents and orthodontic wires), aerospace, industrial manufacturing, and consumer products.

Nitinol Powder

Nitinol Powder is primarily composed of nickel and titanium. It is widely applied in additive manufacturing (3D), metal injection molding (MIM), and coating technology, providing great flexibility and precision in manufacturing complex geometries. HM can offer high-quality Nitinol Powder in a wide range of particle size distributions, which can be customized to meet the specific requirements of various applications.

Nitinol Powder Material Chemical Composition

| Chemical Composition | ||||||||

| Element | Value (%) | Test Method | Element | Value (%) | Test Method | |||

| Ni | 40-50 | – | Mo | <0.01 | ICP-AES | |||

| Ti | 50-60 | – | Si | <0.01 | ICP-AES | |||

| Al | <0.1 | ICP-AES | Fe | <0.05 | ICP-AES | |||

| Cu | <0.03 | ICP-AES | Mg | <0.02 | ICP-AES | |||

| Gas Impurities | ||||||||

| Element | Value (%) | Element | Value (%) | |||||

| C | <0.005 | O | <0.10 | |||||

| N | <0.008 | |||||||

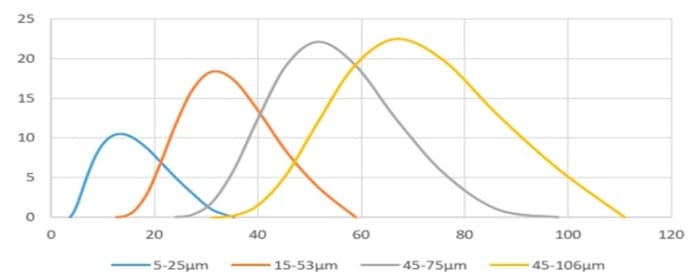

Nitinol Powder Particle Size Distribution

- 5-25μm

- 15-45μm

- 15-53μm

- 45-75μm

- 45-105μm

- 75-150μm

- Various granularities can be customized according to customer requirements

Nitinol Spherical Powder Morphology

Nitinol Powder Applications

- Additive Manufacturing (3D Printing): Produces complex NiTi parts, such as medical implants (custom bone scaffolds, dental components) and lightweight aerospace structures.

- Surface Coatings: Applied via thermal or cold spraying to enhance wear resistance, corrosion resistance, and superelasticity on mechanical parts or tools.

- Smart Material Development: Used to develop new shape memory components, like micro-actuators or sensors, for robotics and flexible electronics.

- Powder Metallurgy Products: Pressed and sintered into high-precision parts for automotive (dampers), industrial (valves), or energy applications (thermal conversion components).

Nitinol Powder Packaging

Nitinol Powder products are carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Powder Products

Heeger Metal offers a comprehensive range of metal powder products, including spherical powders, and nano powders. Our high-quality metal powders are ideal for applications in 3D printing, powder metallurgy, electronics, and advanced manufacturing. These powders provide excellent consistency, flowability, and particle size distribution, ensuring superior performance in various industrial processes. Whether you need custom metal powders or standard alloy powders, our products meet the highest quality standards for precision and reliability.

Other Nitinol Products

Heeger Metal offers a comprehensive range of titanium alloy products, including Nitinol, in various forms such as powders and finished parts, with customization options available. Known for its unique shape-memory properties, exceptional strength, corrosion resistance, and biocompatibility, Nitinol is ideal for use in medical devices, aerospace, robotics, and other advanced engineering applications.