Nitinol Rod

Nitinol Rod

Material: NiTi, NiTiFe, NiTiCu, NiTiCo, NiTiCuCr, etc.

Standard: ASTM F2063-12

Nitinol Rod is made from nickel and titanium in a near 1:1 ratio. It has a unique shape memory effect and superelasticity, widely used in medical devices, aerospace, robotics, and consumer electronics. As a leading supplier and manufacturer of premium nitinol alloys products, Heeger Metal leverages advanced technology to deliver high-quality nitinol rods for various applications.

Or email us at sales@heegermaterials.com.Nitinol Rod Data Sheet

| Material: | NiTi, NiTiFe, NiTiCu, NiTiCo, NiTiCuCr, etc. |

| Standard: | ASTM F2063-12 |

| Diameter: | >0.2″, or customized |

| Available Shape: | Rod, Bar, Rectangular bar, Threaded Rod, or customized |

| Surface: | Black, Pickled, or Polished |

| Af Temperature: | -10 ℃ to 120 ℃ |

What Is The Nitinol Alloy?

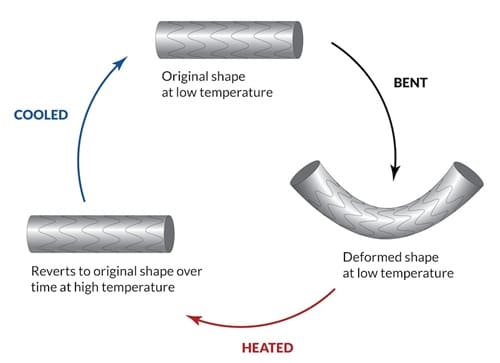

Nitinol, also called NiTi shape memory alloy, is a metal alloy composed of nickel and titanium, typically in a near 1:1 ratio. It has a unique shape-memory effect and superelasticity, allowing it to return to a preset shape when heated or recover its original form after significant deformation. It offers an expansion rate of over 20%, a fatigue life of 107 cycles, damping properties ten times greater than regular springs, and superior corrosion resistance compared to stainless steel. Due to its excellent biocompatibility, corrosion resistance, and mechanical properties, Nitinol alloy is widely used in medical devices (e.g., stents and orthodontic wires), aerospace, industrial manufacturing, and consumer products.

Nitinol Rod

Nitinol Rod is known for its unique shape memory effect and superelasticity. At room temperature, the Nitinol rod can undergo significant deformation and fully recover its original shape, while heating it to a specific temperature triggers its ability to “remember” and return to a pre-set form. It also has excellent biocompatibility, corrosion resistance, and high fatigue life, making it widely applied in medical devices. There are two main types of superelastic and shape-memory materials based on their transition temperature. HM can offer customized solutions for diameter and surface state according to specific requirements.

Nitinol Rod Mechanical Properties: Superelastic Grades

| Cold Worked | Superelastic | |||||||

| Grade | Ingot As(℃) | Min. Uts(psi) | Elongation(%) | Min. Uts(psi) | Elongation(%) | Loading Plateau(ksi) | Unloading Plateau(ksi) | Active Af (℃) |

| Nitinol #1 | -35 to -10 | 220,000 | >4 | 180,000 | >10 | >70,000 | >20,000 | +10 to +18 |

| Nitinol #2 | -45 to -15 | 250,000 | >4 | 210,000 | >10 | >80,000 | >35,000 | 0 to +18 |

| Nitinol #4 | -10 to +10 | 220,000 | >4 | 180,000 | >10 | >65,000 | >7,000 | +14 to +22 |

| Nitinol #9 | ≥ +35 | 220,000 | >4 | 160,000 | >10 | >75,000 | >25,000 | ≤0 |

Nitinol Rod Mechanical Properties: Shape-Memory Grades

| Cold Worked | Shape-memory | |||||||

| Grade | Ingot As(℃) | Min. Uts(psi) | Elongation(%) | Min. Uts(psi) | Elongation(%) | Loading Plateau(ksi) | Unloading Plateau(ksi) | Active Af (℃) |

| Nitinol #5 | ≥ +85 | 220,000 | >3 | 160,000 | >10 | N/A | N/A | ≥ +85 |

| Nitinol #6 | +35 to +85 | 220,000 | >3 | 160,000 | >10 | N/A | N/A | +40 to +80 |

| Nitinol #8 | +10 to +35 | 220,000 | >3 | 160,000 | >10 | N/A | N/A | +22 to +40 |

Nitinol Rod Material Chemical Composition

| Chemical Composition (wt%) | ||||

| Fe | Ni | Cr | Cu | Nb |

| ≤0.05 | 54.5-57.0 | ≤0.01 | ≤0.01 | ≤0.025 |

| C | Ti | Co | N+O | H |

| ≤0.05 | Balanced | ≤0.05 | ≤0.050 | ≤0.005 |

Nitinol Rod Advantages

- Shape Memory

- Superelasticity

- Sensitivity to Oral Temperature Changes

- Excellent Corrosion Resistance

- Anti-Toxicity

- Gentle Orthodontic Force

- Good Damping Characteristics

Nitinol Rod Surface Finish

- Black: The surface is “as swaged” or “as drawn”, retaining a coating of processing lubricants and oxides.

- Cleaned: The surface is chemically cleaned to remove all lubricants and oxides.

- Ground: The surface is centerless to remove all coating and achieve precise dimensions control.

Nitinol Rod Applications

Medical Field:

- Orthopedic Implants: Nitinol bars are widely used in orthopedics, such as for spinal fixation, fracture repair, and artificial joints.

- Dental Equipment: Nitinol bars make dental orthodontic wires and endodontic tools, offering excellent flexibility and shape memory.

- Vascular Stents: Nitinol bars can be made into vascular stents, used to treat arterial stenosis or aneurysms.

Industrial Applications:

- Aerospace Components: Nitinol bars are used in aerospace for parts like temperature sensors and shape memory components.

- Robotics: Nitinol bars have significant applications in robotics, enabling the creation of flexible robotic hands and bionic structures.

- Sensors and Actuators: Nitinol bars can be used to manufacture temperature sensors and thermal actuators, widely used in automatic control systems.

Consumer Products:

- Eyeglass Frames: Nitinol bars are used to make eyeglass frames with shape memory properties, allowing them to return to their original shape after being bent.

- Elastic Jewelry: Nitinol bars can be made into jewelry that is both elastic and durable, adapting to various shapes and sizes.

- Sports Equipment: Nitinol bars are used to produce high-performance sports equipment, such as golf clubs and fishing rods.

Nitinol Rod Packaging

Nitinol Rod products are carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Rod/Bars Products

Heeger Metal supplies refractory metal and alloy rods/bars made from high-performance materials like tungsten, molybdenum, and tantalum. These rods offer excellent strength, high melting points, and resistance to wear and corrosion, making them ideal for aerospace, electronics, and high-temperature applications. Available in various sizes, they can be customized to meet specific needs.

Other Nitinol Products

Heeger Metal offers a comprehensive range of titanium alloy products, including Nitinol, in various forms such as powders and finished parts, with customization options available. Known for its unique shape-memory properties, exceptional strength, corrosion resistance, and biocompatibility, Nitinol is ideal for use in medical devices, aerospace, robotics, and other advanced engineering applications.