Palladium Silver Alloy Tube

Palladium Silver Alloy Tube

Material: PdAg23, PdAg25, PdAg30, PdAg40

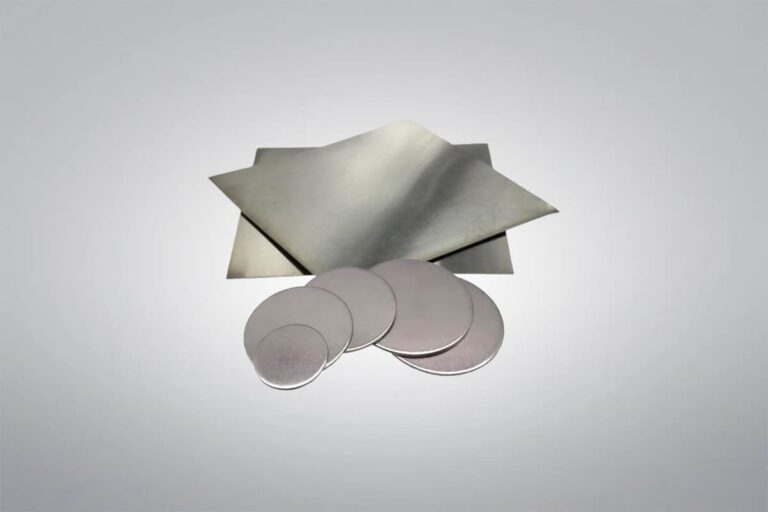

Palladium Silver Alloy Tube is a high-performance material composed of palladium and silver, widely used as electrical contact material, resistance strain material, high-purity hydrogen purification material, fuel cell electrodes, solders, etc. As a leading supplier and manufacturer of premium palladium products, Heeger Metal leverages advanced technology to deliver high-quality palladium silver alloy tubes for various applications.

Or email us at sales@heegermaterials.com.Palladium Silver Alloy Tube Data Sheet

| Reference Code: | HMPA2714 |

| Material: | PdAg23, PdAg25, PdAg30, PdAg40 |

| Purity: | 99.95%, or customized |

| Temper: | Annealed or Unannealed |

Palladium Silver Alloy Tube Description

Palladium Silver Alloy Tube is made of high-performance palladium and silver. It possesses excellent corrosion resistance, electrical conductivity, and oxidation resistance, maintaining stability under high temperatures and harsh environments. The most commonly used composition is Pd75Ag25. We can also provide customized compositions based on specific requirements, such as PdAg10, PdAg23, PdAg30, PdAg40, PdAgCu, PdAgAuNi, etc. Heeger Metal can supply high-precision palladium silver tubes in various specifications to suit different industrial and research applications, ensuring optimal performance and cost-effectiveness.

Palladium Silver Alloy Tube Tolerances

| Outside Diameter | =<2mm | ±0.05mm |

|---|---|---|

| Outside Diameter | 2mm – 5mm | ±0.1mm |

| Outside Diameter | >5mm | ±5% |

| Wall Thickness | ±10% |

Palladium Silver Alloy Tube Applications

- Electronics Industry: Used in manufacturing high-precision electronic components such as connectors, cables, and sensors, due to their excellent electrical conductivity and corrosion resistance.

- Medical Industry: Palladium silver alloy tubes are used in producing medical devices and instruments, especially in environments where high strength and corrosion resistance are required.

- Chemical Industry: In chemical reactors, catalyst supports, and reaction tubes, palladium silver alloy is widely used for its high-temperature and corrosion-resistant properties.

- Aerospace Industry: Due to their high temperature resistance and strength, palladium silver alloys are used in manufacturing high-end equipment and components in the aerospace sector.

Palladium Silver Alloy Tube Packaging

Palladium Silver Alloy Tube is carefully placed in wooden cases or cartons with additional soft materials to support and prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Palladium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tube/Pipe Products

Heeger Metal provides high-quality custom tube and pipe products in a variety of materials including stainless steel, titanium, nickel alloys, and more. Our precision tubes and pipes are available in various sizes and forms, ideal for applications in industries such as aerospace, automotive, energy, and chemical processing. Whether you require seamless tubes, welded pipes, or custom-cut solutions, we deliver products designed to meet your exact specifications with superior strength, corrosion resistance, and long-lasting performance.