Silver Bonding Wire

Silver Bonding Wire

Purity: ≥99.95%, or customized

Diameter: ≥0.018 mm, or customized

Silver Bonding Wire is a high-performance conductive material specially designed for the packaging and electrical connections of electronic components. It is made from high-quality silver and silver alloy through special techniques, offering extremely low electrical resistance and excellent oxidation resistance. As a leading supplier and manufacturer of premium silver products, Heeger Metal leverages advanced technology to deliver high-quality silver bonding wires for various applications.

Or email us at sales@heegermaterials.com.Silver Bonding Wire Data Sheet

| Reference Code: | HMSI2709 |

| CAS: | 7440-22-4 |

| Purity: | ≥99.95%, or customized |

| Density: | 10.503 g/cm3 |

| Melting Point: | 961.78℃ |

| Boiling Point: | 2162℃ |

| Diameter: | ≥0.018 mm, or customized |

| Temper: | Annealed or Unannealed |

Silver Bonding Wire Description

Silver Bonding Wire is made from high-purity silver (5N and above) and utilizes proprietary alloying casting and processing technologies. This effectively addresses issues such as rapid diffusion of silver-aluminum intermetallic compounds and performance degradation, while significantly enhancing corrosion resistance, making it an excellent alternative to gold wire. Silver bonding wire is widely used in integrated circuits and semiconductor devices, and slightly thicker wires can also be used to manufacture audio cables. As a metal bonding material, Heeger Metal provides bonding wires in gold (Au), silver (Ag), copper (Cu), and aluminum (Al), with fine wires (10-38μm) and thicker wires (100-500μm) for power devices. In addition to offering wire with smooth, clean surfaces and good dimensional stability, we also provide comprehensive solutions and expertise in metal bonding.

Silver Bonding Wire Composition and Characteristics

| Type | YA1 | YA2 | YA3 | YA4 |

| Main content | Ag≥99.0% AuPd≤1.0% | Ag≥95.0% AuPd≤5.0% | Ag≥88.0% AuPd≤12.0% | Ag≥85.0% AuPd≤15.0% |

| Characteristics | Low electrical resistivity high thermal conductivity | Good corrosion resistance | good corrosion resistance | Good fatigue resistance |

Silver Bonding Wire Specifications and Mechanical Properties

| Diameter | B/L(gf) | E/L(%) | ||||

| μm | mil | YA1 | YA2 | YA3 | YA4 | YA |

| 15±1 | 0.6 | >1.5 | >2 | >3 | >4 | 2 – 10 |

| 16±1 | 0.65 | >2 | >3 | >4 | >5 | 2 – 10 |

| 18±1 | 0.7 | >4 | >5 | >6 | >7 | 5 – 15 |

| 20±1 | 0.8 | >5 | >6 | >7 | >8 | 5 – 15 |

| 23±1 | 0.9 | >7 | >8 | >10 | >11 | 5- 15 |

| 25±1 | 1.0 | >9 | >10 | >12 | >13 | 5- 15 |

| 30±1 | 1.2 | >13 | >14 | >15 | >16 | 8- 18 |

| 32±1 | 1.25 | >15 | >16 | >17 | >18 | 8 – 18 |

| 38±1 | 1.5 | >20 | >21 | >22 | >23 | 10 – 20 |

| 50±2 | 2.0 | >34 | >36 | >38 | >40 | 10 – 20 |

| 75±3 | 3.0 | >68 | >70 | >75 | >78 | 15 – 25 |

Silver Bonding Wire Fusing Current and Hardness

| Type | YA1 | YA2 | YA3 | YA4 | ||

| μm | mil | |||||

| Fusing Current (A,10mm) | 18 | 0.7 | 0.38 | 0.35 | 0.32 | 0.30 |

| 20 | 0.8 | 0.49 | 0.45 | 0.42 | 0.39 | |

| 23 | 0.9 | 0.62 | 0.57 | 0.53 | 0.48 | |

| 25 | 1.0 | 0.76 | 0.70 | 0.64 | 0.61 | |

| 30 | 1.2 | 1.07 | 0.99 | 0.91 | 0.89 | |

| 38 | 1.5 | 1.66 | 1.54 | 1.42 | 1.37 | |

| 50 | 2.0 | 2.91 | 2.74 | 2.52 | 2.43 | |

| Hardness (Hv) | Wire | 56-61 | 59-64 | 61-66 | 63-68 | |

| FAB | 50-55 | 53-58 | 55-59 | 56-60 | ||

Silver Bonding Wire Features

- Excellent conductivity

- Excellent heat dissipation

- Good reflectivity

- Good solderability

Silver Bonding Wire Applications

Silver Bonding Wire plays a crucial role in connecting chips with circuits, packaging optoelectronic devices, and transmitting signals in sensors, ensuring efficient and stable electrical connections between electronic components. The application fields include semiconductor packaging, integrated circuit connections, optoelectronic device packaging, sensors, and automotive electronics. Here are the specific applications of every type:

| YA1 | YA2 | YA3 | YA4 |

| Common | LED TR IC CARD QFN TSOP Flash Memo | LED QFP TSSOP QFN DFN IC CARD MQFP PBGA TQFP BGA Flash Memo | TQFP TSSOP PBGA BGA |

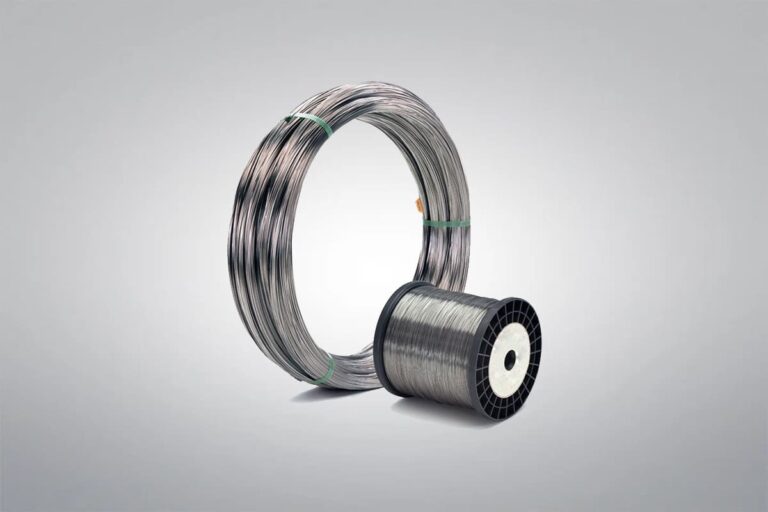

Silver Bonding Wire Packaging

Silver Bonding Wire is carefully placed in wooden cases or cartons with additional soft materials to support and prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Silver Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Wire Products

We specialize in providing high-quality custom wire products, including straight wires, coiled wires, and thermal spray wires. We offer various materials such as tungsten, molybdenum, nickel alloys, and more, ensuring precision and performance for diverse industrial applications. Whether you need wires for manufacturing, coating, or specialized coatings like thermal spraying, our custom wire solutions are designed to meet your specific requirements with superior strength and reliability.