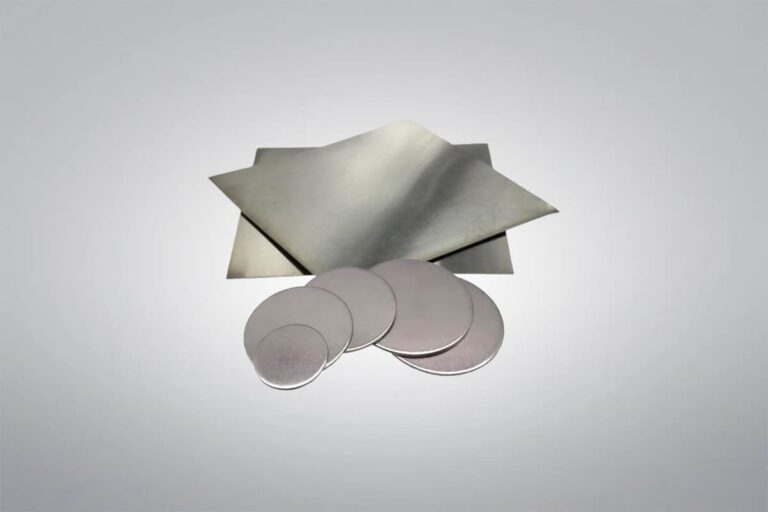

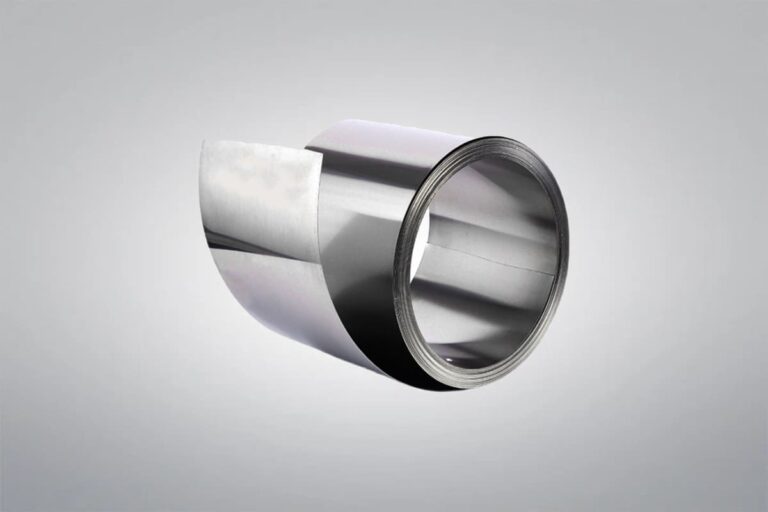

Silver Foil/Strip/Ribbon

Silver Foil/Strip/Ribbon

Purity: ≥99.95%, or customized

Silver Foil/Strip/Ribbon is made from high-purity silver metal through precise rolling and cutting techniques to achieve thin and flexible forms. It offers excellent electrical conductivity, corrosion resistance, and thermal conductivity, available in various thicknesses and forms. As a leading supplier and manufacturer of premium silver products, Heeger Metal leverages advanced technology to deliver high-quality silver foils, strips, and ribbons for various applications.

Or email us at sales@heegermaterials.com.Silver Foil/Strip/Ribbon Data Sheet

| Reference Code: | HMSI2710 |

| CAS: | 7440-22-4 |

| Purity: | ≥99.95%, or customized |

| Density: | 10.503 g/cm3 |

| Melting Point: | 961.78℃ |

| Boiling Point: | 2162℃ |

| Delivery State: | Hard, Semi-hard, or Soft states as specific requirements |

| Temper: | Annealed or Unannealed |

Silver Foil/Strip/Ribbon Description

Silver (Ag) is a precious metal known for its highest electrical conductivity, thermal conductivity, and reflectivity of any metal. Additionally, it also has excellent resistance to corrosion and oxidation. Silver Foil/Strip/Ribbon is made of high-purity silver metal, widely applied in semiconductor fabrication as a conductive layer for thin-film devices and integrated circuits. Heeger Metal can supply high-quality silver foils, strips, and ribbons in various specifications and customized solutions to suit industrial and research applications, ensuring optimal performance and cost-effectiveness.

Silver Foil/Strip/Ribbon Tolerances

| Thickness | <0.01mm | ±25% |

|---|---|---|

| Thickness | 0.01mm – 0.05mm | ±15% |

| Thickness | >0.05mm | ±10% |

Silver Foil/Strip/Ribbon Manufacturing Processes

- Material Preparation: The process begins with high-purity silver, which is typically in the form of silver ingots or pellets. These materials are carefully selected to ensure high conductivity and quality.

- Melting and Alloying: The silver ingots are melted at high temperatures in a furnace. In some cases, small amounts of other metals (such as copper) may be added to enhance the strength and durability of the final product.

- Rolling: Once the silver is molten and properly alloyed, it is poured into molds and cooled to form solid blocks or slabs. These blocks are then passed through a series of rollers in a rolling mill. The silver is repeatedly passed through rollers to reduce its thickness and achieve the desired form, whether it’s foil, strip, or ribbon. The rolling process is done under controlled conditions to prevent the material from becoming brittle.

- Annealing: After rolling, the silver is often annealed, which involves heating the metal in a furnace to relieve internal stresses and improve flexibility. This makes the silver more ductile and easier to shape.

- Cutting and Shaping: The rolled silver is then cut into strips, ribbons, or foil of specific sizes. The cutting process can be done using laser cutting or precision shearing techniques to achieve accurate dimensions and smooth edges.

- Finishing: The silver foil, strip, or ribbon is then polished to improve its surface appearance and quality. It may also undergo additional treatments like coating or electroplating, depending on the final use.

- Quality Control: Throughout the entire process, quality control measures are in place to ensure that the silver products meet the required standards for conductivity, thickness, and appearance.

Silver Foil/Strip/Ribbon Applications

- Electronics: Silver foil, strip, and ribbon are widely used in electronic components due to their excellent electrical conductivity. They are commonly used in connectors, conductors, capacitors, and batteries to enhance performance and efficiency.

- Solar Panels: Silver foil is used in the production of solar cells for its high conductivity and durability. It helps to improve the efficiency of solar panels by enabling better current flow and reducing energy loss.

- Aerospace: Silver foil is used in aerospace applications for shielding and thermal protection. Its high conductivity and lightweight nature make it an ideal material for components that need to withstand extreme temperatures while maintaining performance.

- Medical Devices: Silver foil, strip, and ribbon are used in certain medical devices and equipment, particularly in areas where electrical conductivity and antibacterial properties are crucial, such as in electrodes and wound care products.

Silver Foil/Strip/Ribbon Packaging

Silver Foil/Strip/Ribbon is carefully placed in wooden cases or cartons with additional soft materials to support and prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Silver Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Foil/Strip/Ribbon Products

Heeger Metal provides a wide range of metal foil, metal strip, and metal ribbon products. Our foil and strip materials are precision-engineered for applications requiring high strength, flexibility, and thermal stability, ideal for electronics, aerospace, and industrial sectors. Whether you need custom metal ribbons or thin metal strips, our products deliver superior performance and reliability.