Tantalum Crucible

Tantalum Crucible

Standard: ASTM B365

Material: R05200, R05400, R05252, R05255, R05240

Tantalum Crucible is manufactured incomplicance with ASTM B365 standards. Custom dimensions and shapes are available to meet individual requirements. Heeger Materials also supplies other tantalum parts (including heaters, heat insulation screens, sheets, supports, etc.) applied in the process of sapphire growth and rare-earth melting.

Or email us at max@heegermaterials.com.Tantalum Crucible Data Sheet

| Reference: | HMTA0013 |

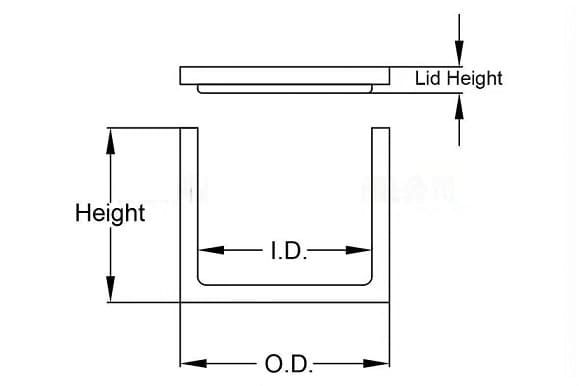

| Dimensions: | Outer Diameter: 10-500 mm Height: 10-600 mm Or customized according to specific drawings |

| Standard: | ASTM B365 |

| Material: | R05200, R05400, R05252, R05255, R05240 |

| Purity: | 99%, 99.9%, 99.95%, 99.99%, 99.999% |

| Form: | Seamless or Welded |

| Temper: | Annealed or Unannealed |

Tantalum Crucible

Tantalum Crucibles are primarily used in material processing, melting, and synthesis under extreme conditions. They are available in two main forms: seamless and welded. The seamless tantalum crucible is produced using a seamless process that meets requirements. The welded tantalum crucible is made from flat-rolled material through an automatic or semiautomatic fusion welding process without filler metal.

Tantalum Crucible Dimensions

HM can provide customized services based on specific customer requirements. The standard dimensions are as follows:

| Diameter (mm) | Wall Thickness (mm) | Height (mm) |

| 30~50 | 2~10 | 30-500 |

| 50~100 | 3~15 | |

| 100~150 | 3~15 | |

| 150~200 | 5~20 | |

| 200~300 | 8~20 | |

| 300~400 | 8~30 | |

| 400~450 | 8~30 | |

| 450~500 | 8~30 |

Tantalum Crucible Applications

- High-temperature materials processing: Tantalum crucibles are widely used in the processing of materials at high temperatures.

- Metal melting: Tantalum crucibles are essential for melting metals like platinum, gold, and other high-temperature alloys.

- Chemical synthesis: Tantalum crucibles are commonly used in chemical reactors where corrosion resistance is critical, such as in the production of specialty chemicals and pharmaceuticals.

- Semiconductor industry: Tantalum crucibles are used for refining semiconductor materials such as polysilicon and gallium arsenide.

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Crucible Packaging

The Tantalum Crucible is carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tantalum Products

Heeger Metal offers a comprehensive range of tantalum and tantalum alloy products, renowned for their outstanding corrosion resistance, high melting point, and stability in harsh environments. These characteristics make them ideal for demanding applications in the aerospace, electronics, and chemical processing industries. Our high-purity tantalum materials deliver exceptional performance and reliability in challenging conditions.

Other Crucible Products

Heeger Metal specializes in high-quality customized metal crucibles and alloy crucibles, designed to withstand extreme temperatures for melting and casting applications. Made from durable materials, our crucibles ensure excellent performance in industries such as metallurgy and material science. For more details or custom solutions, feel free to contact us.