Tantalum Foam

Tantalum Foam

Material: Tantalum (Ta)

Purity: >99%

Tantalum Foam is a porous 3-dimensional structure material, made of high-purity non-toxic tantalum. It is commonly considered as an ideal biomedical metal material due to its biocompatible, good corrosion resistance, and good osteoinductive. As a leading supplier and manufacturer of premium tantalum products, Heeger Materials leverages advanced technologies to deliver high-precision tantalum foam for wide ranges of applications .

Or email us at max@heegermaterials.com.Tantalum Foam Data Sheet

| Reference: | HMTA0018 |

| Structure: | 3-dimensional connected, dodecahedral structure |

| Specifications: | Cell Size (PPI): 400-600 μm Thickness: customized |

| Material: | Tantalum |

| Purity: | >99% |

| Form: | Sheet, Roll, or Sector |

Tantalum Foam

HM is a professional supplier and manufacturer of high-quality tantalum foam with various specifications. We can offer customized services according to specific porosity, cell size (PPI), thickness, size, shape, and other parameters.

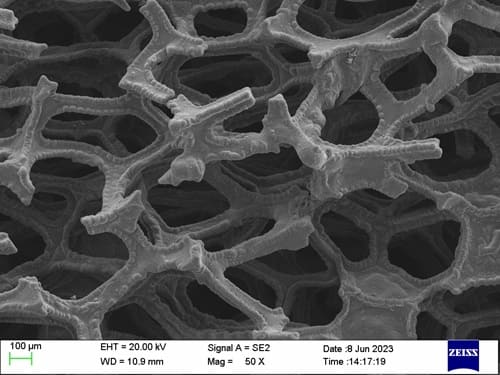

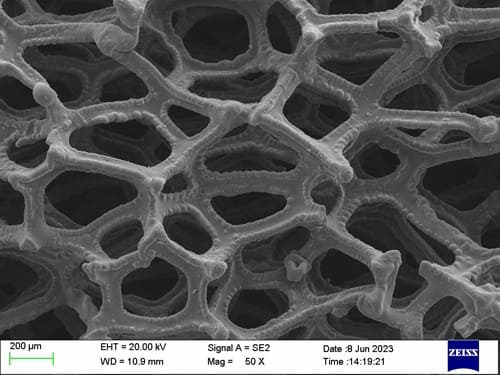

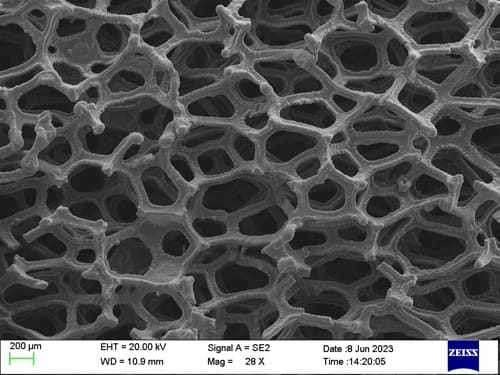

Tantalum Foam Scanning Electron Microscope

A scanning electron microscope (SEM) analysis of tantalum foam reveals its unique porous structure, characterized by interconnected pores and a high surface area. With porosity ranging from 40% to 80%, tantalum foam is lightweight and offers excellent mechanical properties, biocompatibility, and resistance to high temperatures, making it ideal for applications in biomedical, filtration, and heat management fields.

Tantalum (Ta) Foam_SEM_100 μm Tantalum (Ta) Foam_SEM_200μm_1 Tantalum (Ta) Foam_SEM_200 μm_2

Tantalum Foam Porosity and Benefits

Tantalum Foam is a highly porous material made from high-purity tantalum metal, offering a combination of lightweight, high strength, and excellent corrosion resistance. The porosity of tantalum foam, typically ranging from 40% to 80%, significantly enhances its performance in various medical, aerospace, and industrial applications. The foam’s unique structure provides benefits as follows:

- High Surface Area: Enhances catalytic, filtration, and chemical reaction processes.

- Lightweight & High Strength-to-Weight Ratio: Ideal for aerospace and medical applications.

- Thermal Insulation: Reduces heat transfer, useful in high-temperature environments.

- Shock Absorption & Energy Dissipation: Effective for impact resistance and vibration damping.

- Corrosion Resistance: Performs well in aggressive chemical environments.

- Biocompatibility: Supports bone integration in medical implants.

- Sound Absorption: Reduces noise in industrial and construction settings.

- Radiation Shielding: Blocks ionizing radiation in medical and nuclear applications.

- High Impact Resistance: Withstands sudden forces and impacts.

- Customizable Mechanical Properties: Allows tailored strength, deformability, and performance for specific needs.

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace, vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Foam Applications

- Orthopedic Implants: Foam tantalum, with its excellent biocompatibility and bone conductivity, is commonly used in the manufacturing of orthopedic implants such as hip and knee prostheses.

- Dental Implants: Due to its superior mechanical properties and biocompatibility, foam tantalum is also used in dental implants.

- Filtration Materials: The porous structure of foam tantalum makes it an ideal material for filtration applications.

- Catalyst Supports: Foam tantalum’s high surface area and excellent chemical stability make it an ideal choice for catalyst support, widely used in chemical reactions and industrial processes.

- Thermal Management Materials: Foam tantalum has good thermal conductivity, making it suitable for applications in electronic devices and other high heat dissipation requirements.

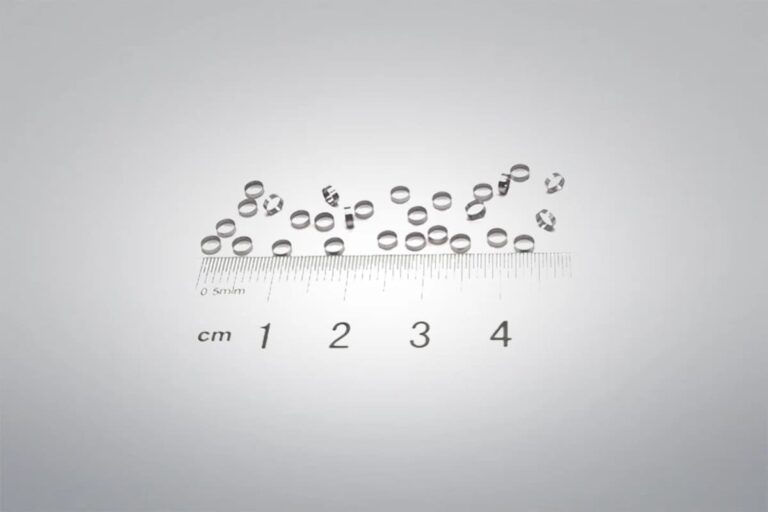

Tantalum Foam Packaging

The Tantalum Foam is carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tantalum Products

Heeger Metal offers a comprehensive range of tantalum and tantalum alloy products, renowned for their outstanding corrosion resistance, high melting point, and stability in harsh environments. These characteristics make them ideal for demanding applications in the aerospace, electronics, and chemical processing industries. Our high-purity tantalum materials deliver exceptional performance and reliability in challenging conditions.

Other Metal Foam Products

Heeger Metal offers a variety of custom metal foams and metal alloy foams, including tungsten foam, aluminum foam, and copper foam. These metal foams provide lightweight, high-strength, and excellent thermal conductivity, perfect for aerospace, automotive, and energy applications. Our porous metal foams and custom alloy foams meet the highest performance standards.