Tantalum Marker Band

Tantalum Marker Band

Standard: ISO13485

Purity: 99.95%, 99.99%

Tantalum Marker Band is a high-performance medical marking component, exhibiting exceptional radiopacity, biocompatibility, and corrosion resistance. As a leading supplier and manufacturer of premium tantalum products, Heeger Metal leverages advanced technology to deliver high-precision tantalum marker bands for various applications.

Or email us at sales@heegermaterials.com.Tantalum Marker Band Data Sheet

| Reference: | HMTA0009 |

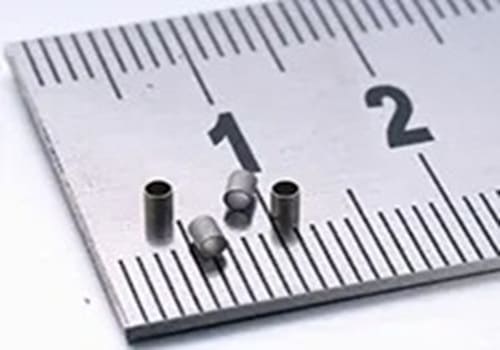

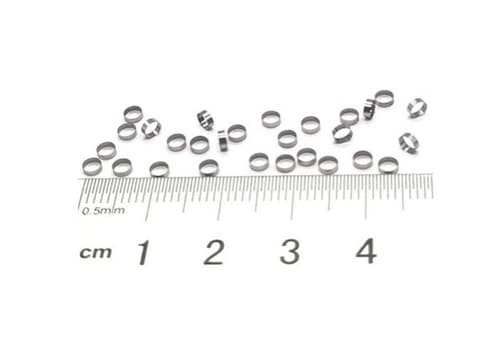

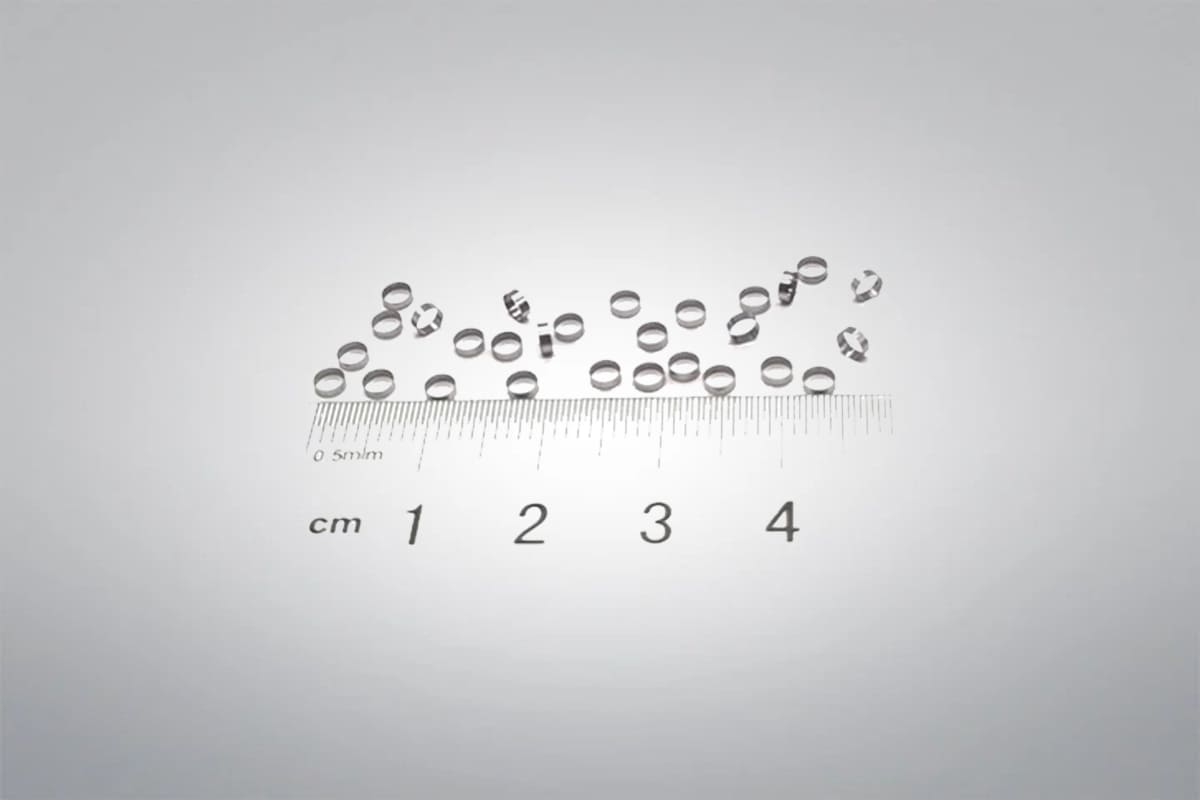

| Dimensions: | Diameter: 0.2-8 mm Wall Thickness: 0.015-0.5 mm Length: Customized |

| Material: | Pure Tantalum |

| Standard: | ISO13485 |

| Purity: | 99.95%, 99.99% |

What Is The Marker Band?

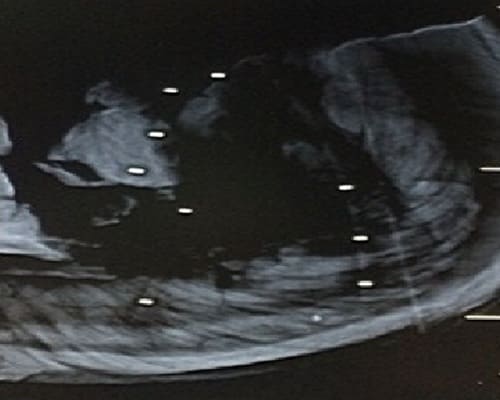

Marker Band is a small, ring-shaped marker used in medical devices, designed to be easily visible in X-rays, CT scans, and other imaging techniques. It helps physicians accurately locate devices or implants. They are commonly used in interventional therapy, minimally invasive surgeries, and implantable medical devices, typically mounted on critical components such as catheters, stents, or guidewires. Due to their extremely small size, thin profile, high dimensional accuracy, and requirement for excellent surface finish and plasticity, marker bands are challenging to manufacture. Materials commonly used, such as tantalum, platinum, and platinum-iridium alloys, provide excellent visibility and biocompatibility, ensuring both surgical precision and safety.

Tantalum Marker Band Platinum Marker Band Platinum-Iridium Marker Band

Tantalum Marker Band

Tantalum marker bands are crucial in interventional devices, valued for their excellent radiopacity, biocompatibility, and corrosion resistance. They are primarily used for precise positioning in catheters, stents, and guidewires, improving visibility under X-ray or fluoroscopy to assist physicians in performing accurate procedures. Compact yet durable, these marker bands can be customized to meet the needs of complex devices, making them essential for angioplasty, cardiac interventions, and minimally invasive surgeries, ensuring both safety and effectiveness. HM offers high-precision tantalum marker bands in a variety of diameters and wall thicknesses to suit specific applications.

Tantalum Marker Band Specifications

| Dimensions | Value | Maximum Tolerance |

| Outer Diameter: | 0.2 – 8 mm | +/- 0.003 mm |

| Wall Thickness: | 0.015 – 0.5 mm | +/- 0.005 mm |

| Length: | Customized | +/- 0.05 mm |

| Appearance: | The finished product must be inspected under a microscope to ensure a uniform metallic luster, absence of discoloration from hydrogenation or oxidation, and no scratches, deformation, or surface pitting. | |

Tantalum Marker Band Features

- High Radiopacity: High density and atomic number provide high contrast in X-ray and CT imaging.

- Good Biocompatibility: Suitable for implantation with no rejection reactions.

- Good Corrosion Resistance: Stable in both in vivo and in vitro environments, resistant to corrosion.

- Excellent Mechanical Properties: High strength, excellent toughness, and fatigue resistance.

- Good Surface Quality: Smooth surface, free from scratches or deformation, with uniform metallic gloss.

Tantalum Marker Band VS. Platinum Iridium Marker Band

Tantalum and Platinum-Iridium marker bands are materials commonly used in medical imaging and implantable devices. The specific comparisons are as follows:

| Property | Tantalum Marker Band | Platinum Iridium Marker Band |

|---|---|---|

| Radiopacity | Moderate to High – Tantalum provides good X-ray contrast, suitable for imaging with lower contrast. | High – Platinum Iridium alloys have excellent X-ray and CT imaging capabilities due to their higher atomic number. |

| Biocompatibility | Very Good – Tantalum is highly biocompatible and widely used for implants. | Very Good – Platinum-iridium alloys also offer excellent biocompatibility, suitable for long-term implantation. |

| Corrosion Resistance | Excellent – Tantalum is highly resistant to chemical and electrochemical corrosion, especially in acidic environments. | Good – Platinum-iridium alloys also provide good corrosion resistance, making them suitable for long-term exposure to bodily fluids. |

| Mechanical Properties | Good – Tantalum has high strength and good ductility but is relatively brittle. | Excellent – Platinum-iridium alloys have exceptional strength, toughness, and fatigue resistance. |

| Manufacturing Difficulty | High – Tantalum is challenging to machine due to its brittleness, requiring specialized techniques. | Moderate – Although platinum-iridium alloys are softer, their high cost adds to the manufacturing complexity. |

| Applications | 1. Vascular intervention devices<br>2. Cardiac pacemakers<br>3. Radiation therapy markers | 1. High-precision medical devices<br>2. Catheters and stents<br>3. Nerve stimulators |

| Cost | Lower – Tantalum is relatively inexpensive. | Very High – Platinum-iridium alloys are costly due to their precious metal content. |

Tantalum Marker Band Platinum-Iridium Marker Band

Tantalum Marker Band Applications

- Interventional Therapy: Used in angioplasty (e.g., balloon dilation) and stent placement, marking catheters or stents to aid precise positioning under X-ray or fluoroscopy.

- Cardiovascular Procedures: Employed in cardiac catheterization or rhythm management devices (e.g., pacemakers) to mark critical locations, ensuring surgical accuracy.

- Minimally Invasive Surgery: Provide clear imaging markers for navigation and positioning in endoscopic or catheter-based procedures.

- Medical Implants: Integrated into implantable devices (e.g., artificial joints, bone repair systems) for post-operative X-ray tracking of position and condition.

- Radiographic Diagnostics: Serve as reference points in X-ray or CT imaging to help identify specific tissue structures or device locations.

Tantalum Maker Band Packaging

The Tantalum Marker Band is carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tantalum Products

Heeger Metal offers a comprehensive range of tantalum and tantalum alloy products, renowned for their outstanding corrosion resistance, high melting point, and stability in harsh environments. These characteristics make them ideal for demanding applications in the aerospace, electronics, and chemical processing industries. Our high-purity tantalum materials deliver exceptional performance and reliability in challenging conditions.