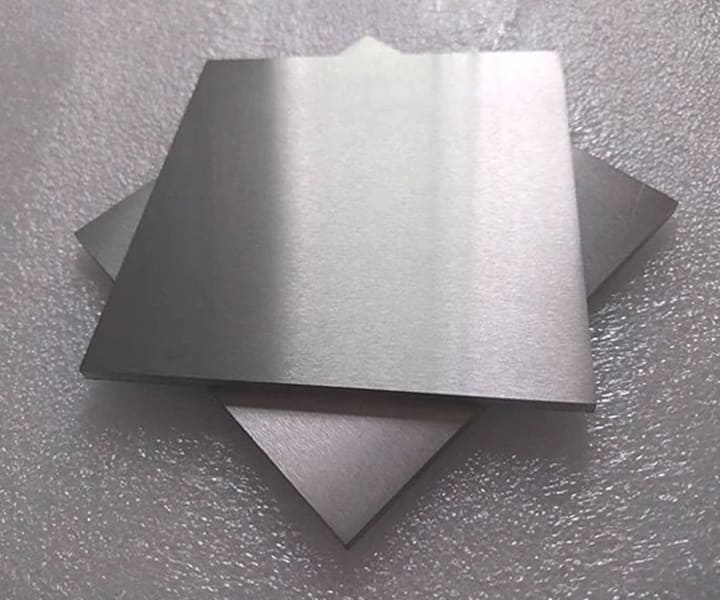

Tantalum Plate/Sheet/Disc

Tantalum Plate/Sheet/Disc

Standard: ASTM B365, ASTM F560 (Medical Grade), ASTM B708

Material: R05200, R05400, R05252, R05255, R05240

Tantalum Plate/Sheet/Disc is manufactured incomplicance with ASTM B365 standards, using high-purity raw materials to ensure excellent corrosion resistance and high-temperature stability. Heeger Materials also supplies tantalum alloy plate/sheet/disc in various specifications, and can provide customized solutions to meet specific reuqirements.

Or email us at max@heegermaterials.com.Tantalum Plate/Sheet/Disc Data Sheet

| Reference: | HMTA0015 |

| Dimensions: | Plate: Thickness >0.1875″ × Width >6″ × Length <7ft Sheet: Thickness 0.001″-0.1875″ × Width >6″ × Length Disc: Diameter 0.1″- 36″ × Thick 0.04″-5″ |

| Standard: | ASTM B708, ASTM B365, ASTM F560 (Medical Grade) |

| Material: | R05200, R05400, R05252, R05255, R05240 |

| Purity: | 99%, 99.9%, 99.95%, 99.99%, 99.999% |

| Temper: | Annealed or Unannealed |

Tantalum Plate

Tantalum and Tantalum Alloy plates are produced through a rolling process, offering exceptional performance and a uniform grain structure. The thickness is typically >0.1875″. The products are strictly manufactured according to ASTM B708 standards and can be customized to meet specific customer requirements.

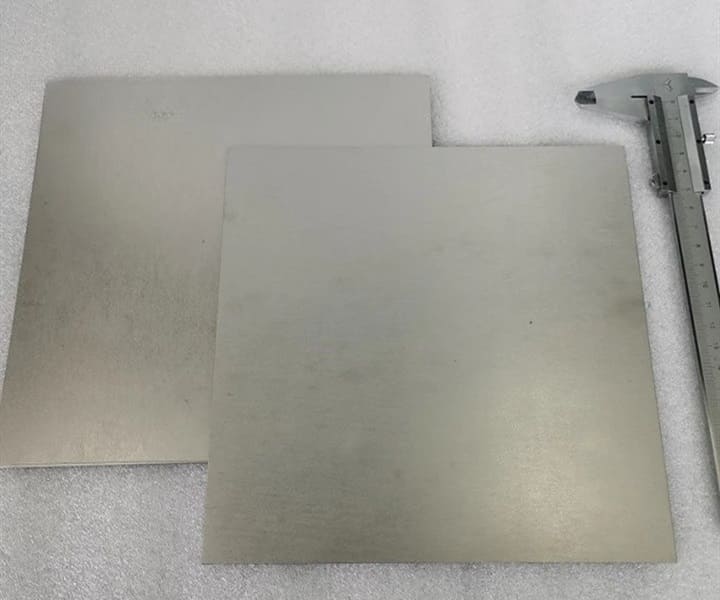

Tantalum Sheet

Tantalum and Tantalum Alloy sheets exhibit excellent deformability even at temperatures below room temperature, allowing for easy punching, cutting, drawing, and pressing. The thickness is typically <0.1875″. HM can cut it to exact dimensions with very tight tolerances.

Tantalum Disc

Tantalum and Tantalum Discs are manufactured through a rolling process. The regular dimensions in stock are as follows:

| Code | Product | Purity | Dimensions |

| EJTTAXX351A2 | Tantalum Disc | Ta, 99.95% | 1.00″ Dia. x 0.125″ Thick |

| EJTTAXX351A4 | Tantalum Disc | Ta, 99.95% | 1.00″ Dia. x 0.250″ Thick |

| EJTTAXX352A2 | Tantalum Disc | Ta, 99.95% | 2.00″ Dia. x 0.125″ Thick |

| EJTTAXX352A4 | Tantalum Disc | Ta, 99.95% | 2.00″ Dia. x 0.250″ Thick |

| EJTTAXX353A2 | Tantalum Disc | Ta, 99.95% | 3.00″ Dia. x 0.125″ Thick |

| EJTTAXX353A4 | Tantalum Disc | Ta, 99.95% | 3.00″ Dia. x 0.250″ Thick |

| EJTTAXX354A2 | Tantalum Disc | Ta, 99.95% | 4.00″ Dia. x 0.125″ Thick |

| EJTTAXX354A4 | Tantalum Disc | Ta, 99.95% | 4.00″ Dia. x 0.250″ Thick |

| EJTTAXX356A4 | Tantalum Disc | Ta, 99.95% | 6.00″ Dia. x 0.250″ Thick |

| EJTTAXX358A2 | Tantalum Disc | Ta, 99.95% | 8.00″ Dia. x 0.125″ Thick |

| EJTTAXX358A4 | Tantalum Disc | Ta, 99.95% | 8.00″ Dia. x 0.250″ Thick |

Tantalum Plate/Sheet/Disc Applications

- Electronics: Tantalum plates, sheets, and discs are widely used in capacitors for communications, computing, automotive electronics, and aerospace applications.

- Chemical Industry: Tantalum plates, sheets, and discs are used in manufacturing reactors, heaters, coolers, and other chemical processing equipment.

- Medical: Tantalum plates, sheets, and discs are used to make medical implants and instruments, including bone plates and sutures.

- Aerospace: Tantalum plates, sheets, and discs are essential for high-temperature components and protective materials in aerospace applications.

- Nuclear: Tantalum plates, sheets, and discs are used in structural materials for nuclear reactors and fuel cladding.

Tantalum and Tantalum Alloy

- R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

- R05400, unalloyed tantalum, powder-metallurgy consolidation.

- R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

- R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

- R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Tantalum Plate/Sheet/Disc Packaging

The Tantalum Plate/Sheet/Disc is carefully placed in wooden cases or cartons, with additional support from soft materials, to prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tantalum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tantalum Products

Heeger Metal offers a comprehensive range of tantalum and tantalum alloy products, renowned for their outstanding corrosion resistance, high melting point, and stability in harsh environments. These characteristics make them ideal for demanding applications in the aerospace, electronics, and chemical processing industries. Our high-purity tantalum materials deliver exceptional performance and reliability in challenging conditions.

Other Plate/Sheet/Disc Products

Heeger Metal offers a wide range of custom plate, sheet, and disc products, available in materials like tungsten, molybdenum, titanium, and nickel alloys. Our precision-engineered products are ideal for various industrial applications, including aerospace, electronics, and energy. Whether you need flat plates, thin sheets, or precision-cut discs, we provide tailored solutions with exceptional strength, durability, and high-performance characteristics to meet your specific requirements.

Disc Products

Heeger Metal offers a wide range of metal and alloy disc products. Our precision-engineered discs are ideal for applications in aerospace, electronics, and industrial sectors, providing excellent strength, durability, and thermal conductivity. Whether you need custom metal discs or standard metal alloy discs, our products ensure high performance and exceptional quality.