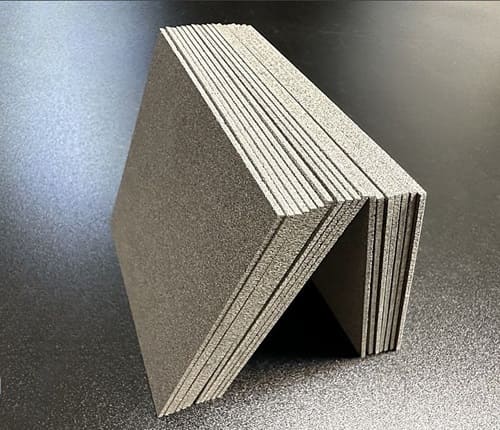

Titanium Foam

Titanium Foam

Material: Purity Titanium

Thickness: 0.5-30 mm

Titanium Foam is a lightweight, porous material made from high-purity titanium powder. It has low density, large specific area, excellent corrosion resistance to acids and alkalis, and good biocompatibility. As a leading supplier and manufacturer of premium titanium products, Heeger Materials leverages advanced technology to deliver high-purity titanium and titanium alloy foams for various applications.

Or email us at sales@heegermaterials.com.Titanium Foam Data Sheet

| Reference: | HMTT1011 |

| Material: | Pure Titanium |

| Porosity: | 25%-45% |

| Thickness: | 0.5-30 mm |

| Specific Surface Area: | 10-40 m2/m3 |

| Filtration Accuracy: | 0.45-100 μm |

| Permeability: | 3-800 M2/M2hKPa |

| Work Temperature: | 300 ℃ |

| Work Pressure: | 2.5 MPa |

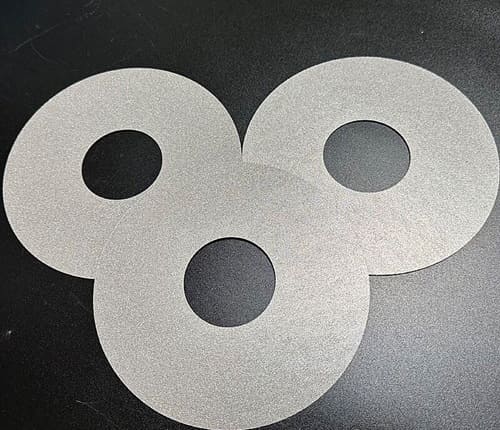

| Shape: | Disc, Sheet, Tube, or Customized |

Titanium Foam

Titanium (Ti), a silver transition metal with a low density of 4.54 g/cm3, exhibits lightweight, high strength, and corrosion resistance. Titanium Foam is made from high-purity titanium powder, which is sieved, molded by cold isostatic pressing, and then sintered under high temperature and vacuum, resulting in a porous material with low density and large specific surface area. HM can supply customized solutions for porosity, cell size, density, thickness, and shape according to specific requirements.

Titanium Foam Material Chemical Composition

| Type | Element (%) | |||||

| N | C | H | Fe | O | Ti | |

| GR.1 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.2 | ≤0.18 | Residual |

| GR.2 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | Residual |

Titanium Foam Specifications

| Product | Length (Diameter) | Width (Diameter) | Thickness |

| Sintered porous disc | ≤φ800 mm | 0.5-30 mm | |

| Sintered porous sheet | ≤800 mm | ≤350 mm | 0.5-30 mm |

| Sintered porous tube | Single≤1200 mm | Out diameter≤φ200 mm | Wall thickness 2-10 mm |

Titanium Foam Advantages

- Uniform structure with a narrow pore size distribution, ensuring high separation efficiency.

- High porosity and low filtration resistance, offering excellent permeability.

- Suitable for use at temperatures up to 280°C.

- Excellent chemical stability, with resistance to both acids and alkalis, as well as antioxidant properties.

- No particle shedding or secondary contamination of the filtered liquid, fully compliant with food safety and pharmaceutical GMP standards.

- Strong mechanical properties, compatible with both press and pump filtration systems, and easy to operate.

- Low differential pressure, compact design, and high flow rate.

- Strong antimicrobial properties, with no adverse reactions to microorganisms.

- High-quality molding process, no welding required, with lengths up to 1000 mm.

- Supports online regeneration, is easy to clean, and offers a long service life.

Titanium Foam Applications

- Biomedical Materials: Titanium foam has excellent biocompatibility and mechanical properties, and is commonly used in bone marrow, joints, blood vessels, and dental restorations.

- Impact-resistant Materials: Due to its unique pore structure, titanium foam can absorb impact energy and resist high stress, making it suitable for applications requiring high strength and impact resistance.

- Filtration materials: Titanium foam is characterized by high filtration efficiency and corrosion resistance, and is commonly used in petrochemical, medical, and other fields for separation and filtration.

- Battery Materials: Titanium foam is used as electrolytic electrode material for manufacturing batteries to increase the electrolytic area.

- Aerospace and Defense: The low density and high strength of titanium foam allow it to be used as a structural material in aerospace and defense applications.

Titanium Foam Packaging

The Titanium Foam is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Titanium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

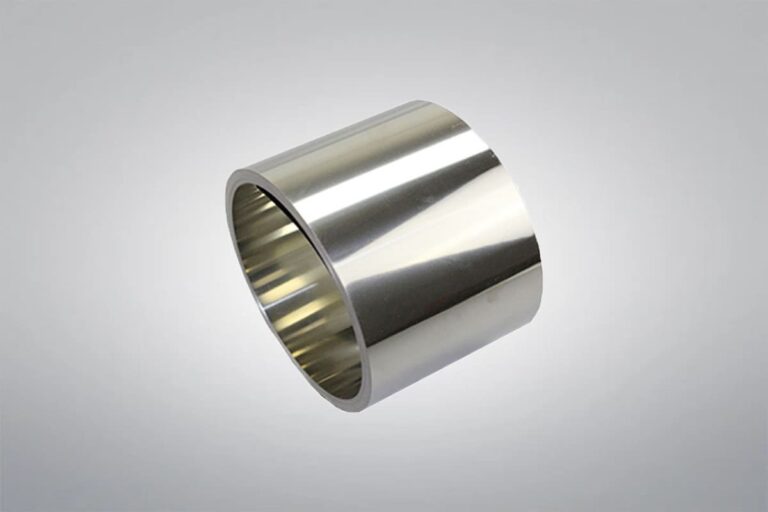

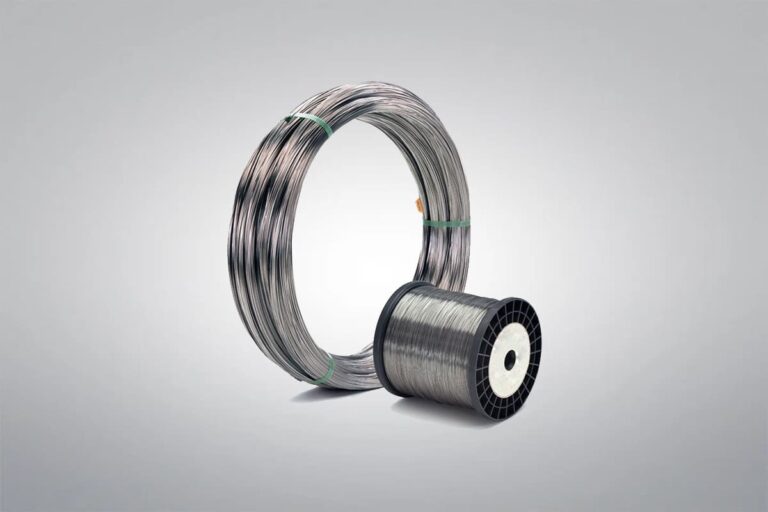

Other Titanium Products

Heeger Metal offers a comprehensive range of titanium and titanium alloy products, including powders and finished parts, with customization options available. Renowned for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are perfect for aerospace, electronics, and chemical processing applications.

Other Metal Foam Products

Heeger Metal offers a variety of custom metal foams and metal alloy foams, including tungsten foam, aluminum foam, and copper foam. These metal foams provide lightweight, high-strength, and excellent thermal conductivity, perfect for aerospace, automotive, and energy applications. Our porous metal foams and custom alloy foams meet the highest performance standards.