Titanium Powder

Titanium Powder

Material: Gr.1, Gr.2, Gr.3, Gr.7, Gr.9, Gr.12, Gr.16, etc.

Purity: 99%-99.5%

Titanium Powder is made from high-purity titanium or titanium alloys. Various grades and particle size distributions are available. We also can offer professional customized solutions to meet the demands of extreme environments and specialized applications. As a leading supplier and manufacturer of premium titanium products, Heeger Materials leverages advanced technology to deliver high-purity titanium and titanium alloy powders for various applications.

Or email us at sales@heegermaterials.com.Titanium Powder Data Sheet

| Reference: | HMTT1009 |

| CAS: | 7440-32-6 |

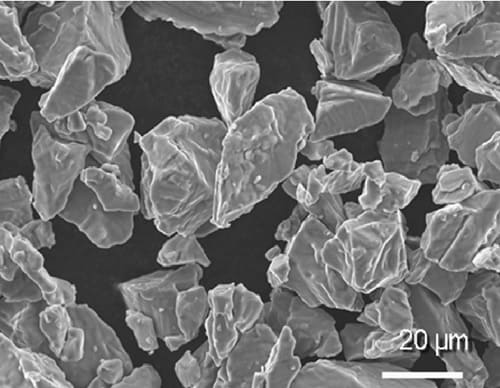

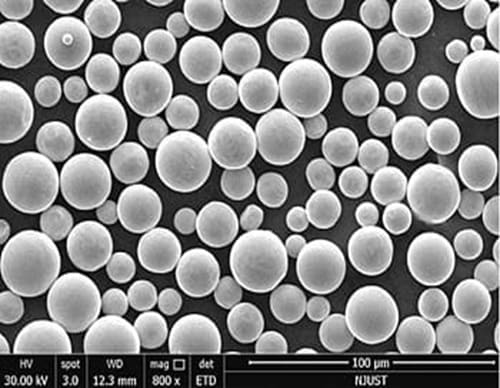

| Particle Shape | Irregular or Spherical |

| Material: | Gr.1, Gr.2, Gr.3, Gr.7, Gr.9, Gr.12, Gr.16, etc. |

| Purity: | 99%-99.5% |

| Particle Size: | 60-400 mesh, 1-10 μm, or customized according to specific requirements. |

Titanium Powder

Titanium (Ti), a silver transition metal with a low density of 4.54 g/cm3, exhibits lightweight, high strength, and corrosion resistance. Titanium Powder is made from high-purity titanium or titanium alloys. Different material grades and particle size distributions are available for multiple demands. Titanium Powder is the ideal raw material for powder metallurgy to manufacture high-strength and lightweight components. HM also can supply high-quality Titanium Spherical Powder with various specifications for the additive manufacturing industry.

Titanium Powder Titanium Powder SEM Titanium Spherical Powder SEM

Titanium Powder Specifications

| Product | Chemical Composition (%) | |||||

| Ti | H | O | N | C | Fe | |

| Ti Powder | ≥99.5 | ≤0.03 | ≤0.2 | ≤0.025 | ≤0.02 | ≤0.03 |

| Particle Size | 60-400 mesh, 1-10 μm, or customized D50 can be as fine as 0.5 μm. | |||||

Titanium Powder Applications

- Powder Metallurgy: Titanium powder can be used in powder metallurgy to produce high-strength, lightweight titanium alloy components, as well as in additive manufacturing to create complex aerospace components, medical devices, and industrial parts.

- Coating: Titanium powder can be used to create wear and corrosion-resistant coatings to improve the service life of mechanical components.

- Electronics Industry: Titanium powder can manufacture high-capacity capacitors, and conductive and barrier layers in semiconductor devices.

Titanium Powder Packaging

The Titanium Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Titanium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Powder Products

Heeger Metal offers a comprehensive range of metal powder products, including spherical powders, and nano powders. Our high-quality metal powders are ideal for applications in 3D printing, powder metallurgy, electronics, and advanced manufacturing. These powders provide excellent consistency, flowability, and particle size distribution, ensuring superior performance in various industrial processes. Whether you need custom metal powders or standard alloy powders, our products meet the highest quality standards for precision and reliability.

Other Titanium Products

Heeger Metal offers a comprehensive range of titanium and titanium alloy products, including powders and finished parts, with customization options available. Renowned for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are perfect for aerospace, electronics, and chemical processing applications.