Titanium Wire

Titanium Wire

Material: Gr.1, Gr.2, Gr.3, Gr.4, etc.

Standard: ASTM SB338, AWS 5.16, ASTM F136 ASTM F67

Titanium wire is made from high-purity titanium metal, known for its excellent corrosion resistance, high strength, low density, and superior biocompatibility. It is widely applied in aerospace, medical, chemical, marine engineering, and automotive manufacturing. As a leading supplier and manufacturer of premium titanium products, Heeger Materials leverages advanced technology to deliver high-purity titanium and titanium alloys wires for wide ranges of applications.

Or email us at sales@heegermaterials.com.Titanium Wire Data Sheet

| Reference: | HMTT1003 |

| Material: | Gr.1, Gr.2, Gr.3, Gr.4, etc. |

| Standard: | ASTM SB338, AWS 5.16, ASTM F136 ASTM F67 |

| Dimension: | Straight Wire.: φ0.04″-φ0.2″ Coiled Wire: φ0.02″-φ0.2″ Customized |

| Temper: | Annealed and Unannealed |

Titanium Wire

Titanium (Ti), a silver transition metal, exhibits lightweight, high strength, and corrosion resistance. Titanium Wire is made from high-quality titanium metal, ensuring superior performance in demanding environments. Its lightweight yet strong properties make it ideal for applications requiring both strength and minimal weight. HM can supply high-precision titanium and titanium alloy wires of various specifications for multiple applications.

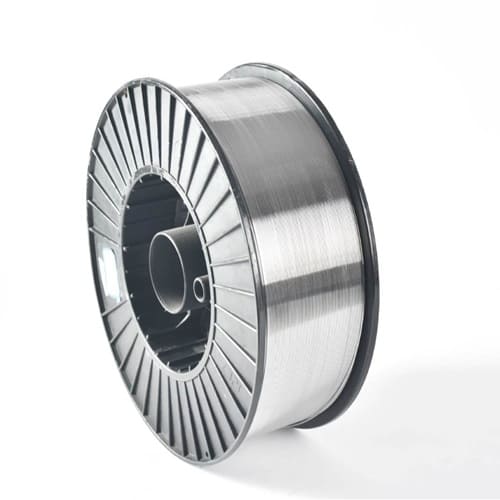

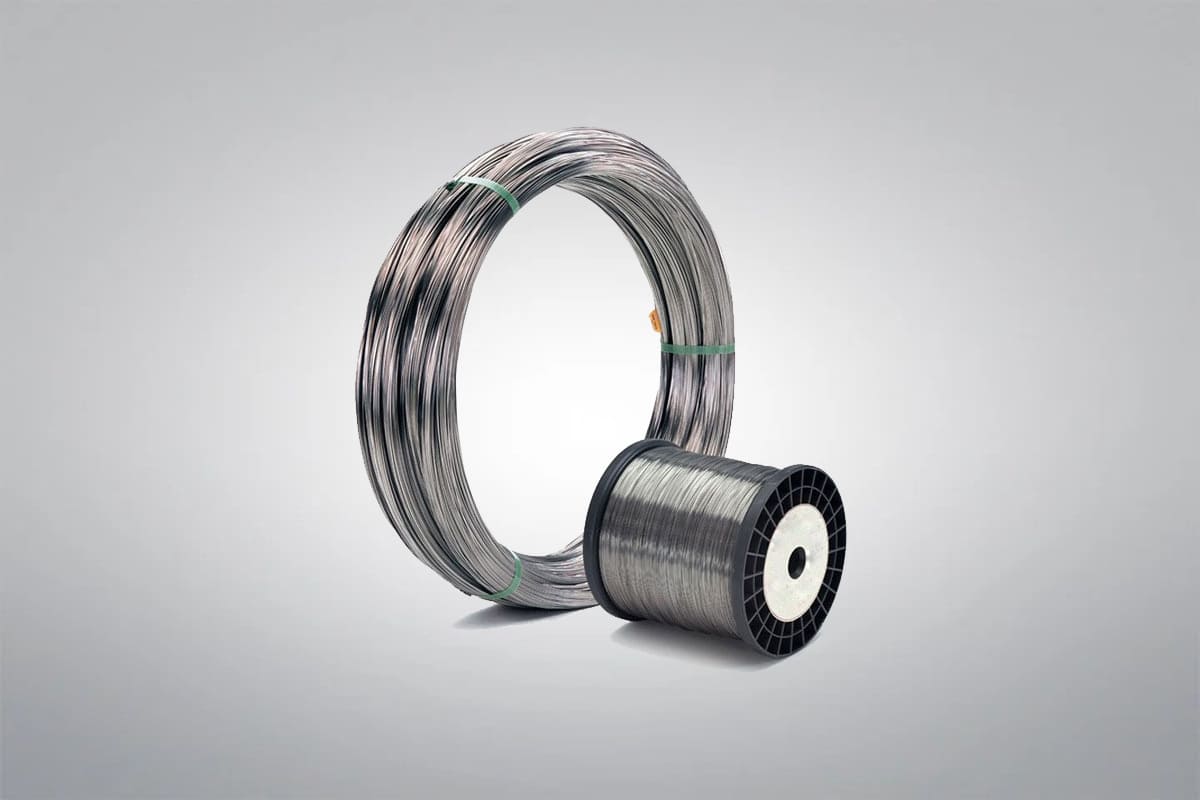

Titanium Straight Wire Titanium Coiled Wire Titanium Spooled Wire

Titanium Wire Material Chemical Composition

| Type | Element (%) | ||||||||||

| N | C | H | Fe | O | Al | V | Mo | Ni | Pd | Ti | |

| GR.1 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.2 | ≤0.18 | Residual | |||||

| GR.2 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | Residual | |||||

| GR.3 | ≤0.05 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.35 | Residual | |||||

| GR.7 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | 0.12-0.25 | Residual | ||||

| GR.9 | ≤0.02 | ≤0.08 | ≤0.015 | ≤0.25 | ≤0.15 | 2.5-3.3 | 2.0-3.0 | Residual | |||

| GR.12 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | 0.2-0.4 | 0.6-0.9 | Residual | |||

| GR.16 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | 0.04-0.08 | |||||

Titanium Wire Specifications

| Form | Size | Standard | Grade | Surface |

| Straight Wire | Dia.: 0.04″-0.2″ (tolerance: +/-0.002″) x 118″ max length | ASTM B863 | Gr.1, Gr.2, Gr.3, Gr.4, etc. | Pickled Polished Customized |

| Coiled Wire | Dia.: 0.02″-0.2″ x L (customized) | |||

| Wire On Spool | Around 300mm (12″) & 110mm for fine titanium wire | |||

| Welding Wire | Customized | AWS 5.16 | ERTi-1, ERTi-2, ERTi-5, ERTi-9 |

Titanium Wire Production Process

- Raw Material Preparation

- Smelting

- Forging/Hot Rolling

- Hot Extrusion

- Drawing (Hot/Cold)

- Heat Treatment

- Surface Treatment

Titanium Wire Surface Finish

Depending on the intended applications, titanium wire has three main surface finishes as follows:

- Black: The surface is “as swaged” or “as drawn”, retaining a coating of processing lubricants and oxides.

- Cleaned: The surface is chemically cleaned to remove all lubricants and oxides.

- Ground: The surface is centerless to remove all coating and achieve precise dimensions control.

Titanium Wire Applications

- Titanium and titanium alloy wires are often used to process fasteners, load-bearing members, springs, etc.

- Titanium and titanium alloy processed titanium welding wire accounts for more than 80% of titanium wire applications.

- Due to its excellent biocompatibility, titanium and titanium alloy wires are widely used in the medical field for making surgical sutures, orthodontic wires, stent implants, and other medical devices.

- Nickel-titanium alloy wires with memory function are used to process satellite antennae, titanium eyeglass frames, etc.

- Titanium and titanium alloy wires are also often used to make various electrodes.

Titanium Wire Packaging

The Titanium Wire is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Titanium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Wire Products

We specialize in providing high-quality custom wire products, including straight wires, coiled wires, and thermal spray wires. We offer various materials such as tungsten, molybdenum, nickel alloys, and more, ensuring precision and performance for diverse industrial applications. Whether you need wires for manufacturing, coating, or specialized coatings like thermal spraying, our custom wire solutions are designed to meet your specific requirements with superior strength and reliability.

Useful Information

Other Titanium Products

Heeger Metal offers a comprehensive range of titanium and titanium alloy products, including powders and finished parts, with customization options available. Renowned for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are perfect for aerospace, electronics, and chemical processing applications.