Molybdenum Crucible

Molybdenum Crucible

Standard: ASTM B387

Material: Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML)

Molybdenum Crucible is made of high-purity molybdenum material, exhibiting high temperature stability, excellent thermal conductivity, and low thermal expansion. As a leading supplier and manufacturer of premium molybdenum products, Heeger Materials leverages advanced machining centers to deliver high-precision molybdenum and molybdenum alloy crucibles for wide ranges of applications.

Or email us at max@heegermaterials.com.Molybdenum Crucible Data Sheet

| Reference: | HMMO1084 |

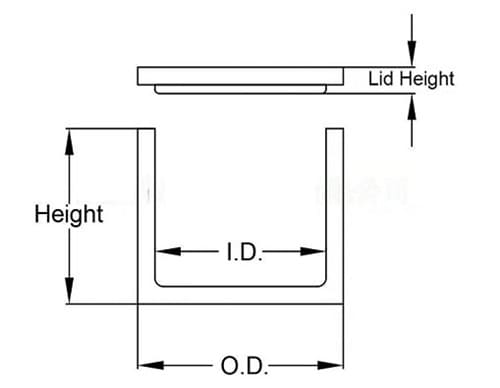

| Dimensions: | Out Diameter: 10-500 mm Height: 10-600 mm |

| Standard: | ASTM B387 |

| Material: | Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML) |

| Purity: | 99.95%-99.99% |

| Type: | Sintered, Spun, Stamped, and Welded |

| Temper: | Annealed or Unannealed |

Molybdenum Crucible

Molybdenum Crucible has a maximum operating temperature of up to 2000℃ and is widely used as a melting container in sapphire crystal growth, rare earth smelting, coating, and other industries. HM can supply high-precision molybdenum and molybdenum alloy crucibles with high purity, high density, no internal cracks, precise dimensions, and smooth inner and outer walls.

Molybdenum Crucible Specifications

| Condition | Size(mm) | Tolerance(mm) | ||

| Diameter (mm) | High (mm) | Diameter (mm) | High (mm) | |

| Sintering | 10-500 | 10-600 | ±5 | ±5 |

| Forging | 10-130 | 10-200 | ±1 | ±2 |

| Sintering and Machining | 100-450 | 10-500 | ±0.5 | ±1 |

Molybdenum Crucible Production Process

Molybdenum Crucibles can be categorized into sintering molybdenum crucibles and spinning molybdenum crucibles according to different production processes. The Sintering Molybdenum Crucibles are mainly used as high-temperature furnace containers in vacuum, inert, or reducing gases up to 2100 ℃. The Spinning Molybdenum Crucibles are thin-walled crucibles made from a single molybdenum plate by spinning. It is characterized by large size, thin wall thickness, and good resistance to high-temperature creep. The specific sintering processes are as follows:

- Raw Material: Select high-purity molybdenum powder.

- Powder Metallurgy: Mix with binder and compact into a green billet.

- Sintering: High-temperature sintering to remove the binder and increase density.

- Heat Treatment: Anneal to relieve stress and enhance properties.

- Surface Treatment: Clean and polish the surface.

- Cutting & Customization: Cut or customize according to requirements.

Molybdenum Crucible Processing Method

- Sintering

- Forging

- Rotary Forging

- Rolling

- Polishing

Molybdenum Crucible Surface Finish

Depending on the intended applications, the molybdenum crucible has three main surface finishes as follows:

- Black: The surface is “as swaged” or “as drawn”, retaining a coating of processing lubricants and oxides.

- Cleaned: The surface is chemically cleaned to remove all lubricants and oxides.

- Ground: The surface is centerless ground to remove all coating and to achieve precise dimensions control.

Molybdenum Crucible Applications

- Rare Earth Metal Smelting: Molybdenum crucibles are commonly used for smelting and casting metals, especially rare earth materials.

- Heat Treatment Of Materials: Molybdenum crucibles are often used as experimental vessels in high-temperature tests.

- Chemical Production: Molybdenum crucibles are also commonly used as reaction vessels or heating platforms in chemical processes requiring high-temperature reactions.

- Sapphire Single Crystal Growth: Molybdenum crucibles are used as core vessels in sapphire single crystal growth furnaces with high purity, high density, and good thermal stability.

Molybdenum Crucible Packaging

The Molybdenum Crucible is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Crucible Products

Heeger Metal specializes in high-quality customized metal crucibles and alloy crucibles, designed to withstand extreme temperatures for melting and casting applications. Made from durable materials, our crucibles ensure excellent performance in industries such as metallurgy and material science. For more details or custom solutions, feel free to contact us.

Other Molybdenum Products

We offer a wide range of molybdenum and molybdenum alloy products, from powders to finished parts, with customization options available. Please refer to the list for our common products.