Tungsten Copper Alloy

Tungsten Copper Alloy

Material: W-Cu Alloy

Standard: ASTM B702

Tungsten Copper Alloy contains 6% to 50% copper, combining the advantages both of copper and tungsten. It is widely used in machinery, electric power, electronics, metallurgy, aerospace and other industries. As a leading supplier and manufacturer of premium tungsten products, Heeger Materials leverages advanced technology to deliver high-purity tungsten copper alloy products for wide ranges of applications.

Or email us at max@heegermaterials.com.Tungsten Copper Alloy Data Sheet

| Reference: | HMWW1133 |

| Material: | CuW50, CuW55, CuW60, CuW65, CuW70, CuW75, CuW80, CuW85, CuW90, or customized |

| Standard: | ASTM B702 |

| Dimensions: | Plate: 300mm x 300mm x 0.5-50mm, customized Rod: 2-200mm dia. x L, customized |

| Temper: | Annealed and Unannealed |

Tungsten Copper Alloy

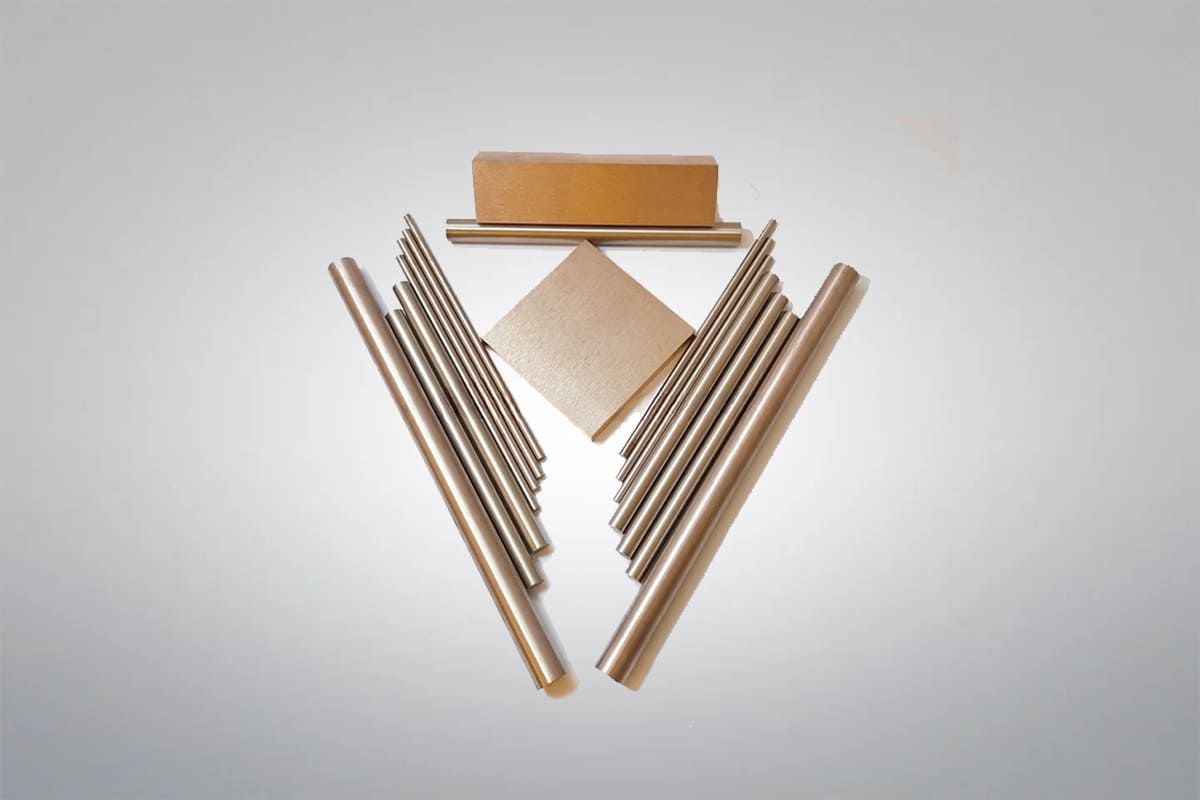

Tungsten Copper Alloy is produced by powder metallurgy, containing 6%-50% copper. Its properties depend mainly on its composition. Alloys with less copper content have higher density, hardness, and resistivity. HM provides high-precision tungsten copper alloy products in various forms, including rods, plates, sheets, bars, tubes, blocks, pellets, wires, and discs, all crafted to ensure exceptional quality and customer satisfaction. We manufacture large, complex parts using isostatic pressure molding technology, while smaller parts are produced through extrusion, molding, and injection molding techniques. Additionally, rods and sheets are fabricated using forging and rolling processes.

Tungsten Copper Alloy Plate Tungsten Copper Alloy Rod Tungsten Copper Alloy Disc

Tungsten Copper Alloy Material Composition And Properties

| Composites | Nominal Composition (% Weight) | Density (g/cm3, ≥) | Electrical Resistivity (20°C, µΩ·cm, ≤) | Electrical conductivity (IACS%, ≥) | Hardness (≥) Brinell Hardness | Bending Strength | ||

| Mpa | Kgf/mm2 | Mpa | Kgf/mm2 | |||||

| CuW50 | 50% Copper 50% Tungsten | 11.85 | 3.2 | 54 | 1128 | 115 | — | — |

| CuW55 | 45% Copper 55% Tungsten | 12.3 | 3.5 | 49 | 1226 | 125 | — | — |

| CuW60 | 40% Copper 60% Tungsten | 12.75 | 3.7 | 47 | 1373 | 140 | — | — |

| CuW65 | 35% Copper 65% Tungsten | 13.3 | 3.9 | 44 | 1520 | 155 | — | — |

| CuW70 | 30% Copper 70% Tungsten | 13.8 | 4.1 | 42 | 1716 | 175 | 667 | 68 |

| CuW75 | 25% Copper 75% Tungsten | 14.5 | 4.5 | 38 | 1912 | 195 | 706 | 72 |

| CuW80 | 20% Copper 80% Tungsten | 15.15 | 5.0 | 34 | 2158 | 220 | 736 | 75 |

| CuW85 | 15% Copper 85% Tungsten | 15.9 | 5.7 | 30 | 2354 | 240 | 765 | 78 |

| CuW90 | 10% Copper 90% Tungsten | 16.75 | 6.5 | 27 | 2550 | 260 | 804 | 82 |

Tungsten Copper Alloy Thermal Properties

| Material Type (wt%) | WCu10 | WCu15 | WCu20 | WCu25 | WCu30 |

| Thermal Conductivity(W/m·K) | >160 | >170 | >180 | >200 | >220 |

| The Coefficient of Thermal Expansion (×10-6/K) | 6.2~6.5 | 6.9~7.2 | 7.4~7.7 | 8.0~8.4 | 8.8~9.4 |

Tungsten Copper Alloy Products Specifications

| Product | Dimensions | Surface |

| Tungsten Copper Plate | Thickness: 0.5-50mm Width×Length: 300mm x 300mm Customized | No coating Electroplated Ni and Ni-Au Electroless Ni |

| Tungsten Copper Rod | Diameter: 2-200mm Length: customized |

Tungsten Copper Alloy Features

- High-temperature resistance

- Resistant to arc abrasion

- High strength

- High specific gravity

- Good thermal and electrical conductivity

- Low thermal expansion

- Easy cutting and machining

Tungsten Copper Alloy Production Process

Tungsten-copper alloy is produced using powder metallurgy. A key manufacturing process for this alloy is infiltration: after compacting the porous tungsten preform, copper is allowed to infiltrate it, followed by sintering. The material is then machined to achieve the required geometry as specified by the customer. Tungsten-copper alloy is a pseudo-alloy of copper and the refractory metal tungsten. Since copper and tungsten are immiscible, the infiltration method is used to achieve bonding between the two materials. The specific processes are as follows:

- Compaction: The porous tungsten preform is compacted.

- Infiltration: Copper is allowed to infiltrate the compacted tungsten preform.

- Sintering: The infiltrated material is sintered at high temperatures, forming a dense solid material.

- Annealing: The sintered products undergo an annealing process to remove internal stresses and improve toughness and ductility.

- Machining: Precision machining processes, such as turning, milling, and grinding, are applied to the sintered parts to achieve final dimensions and shapes.

- Heat Treatment: The alloy undergoes additional heat treatment to optimize properties such as hardness, strength, or other physical characteristics.

- Surface Treatment: If required, surface treatments (such as coating, passivation, etc.) are applied to enhance corrosion resistance, hardness, or other properties.

Tungsten Copper Alloy Machining Service

HM has advanced machining centers equipped with various high-precision processing equipment, enabling us to offer multiple machining services such as turning, milling, grinding, and drilling. Whether for large-scale production or customized small-batch orders, we guarantee high precision and performance to meet customer’s specific requirements. The following are methods we will use during processing:

- Isostatic Pressing

- Forging

- Extrusion

- Molding

- Injection Molding

- Rolling

- Electrical Discharge Machining (EDM)

- Milling

- Turning

Tungsten Copper Alloy Applications

- High-temperature materials: Tungsten-copper alloys have excellent high-temperature resistance and are commonly used in high-temperature parts such as rocket engine nozzles.

- Electrical contacts: Tungsten-copper alloys have high electrical conductivity and arc resistance and are widely used for electrical contacts in high-voltage circuit breakers, switches, and relays.

- Heat sinks: The high thermal conductivity of tungsten-copper alloy makes it ideal for heat sinks in electronic equipment such as integrated circuits and power semiconductors.

- Electrode: Copper tungsten alloy is commonly used as electrode material in electric discharge machining (EDM) and resistance welding.

Tungsten Copper Alloy Packaging

The Tungsten Copper Alloy is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Tungsten Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tungsten Products

Heeger Metal provides a wide range of tungsten and tungsten alloy products, from powders to finished components, with customization options available. Known for their outstanding strength, high melting point, and excellent wear and corrosion resistance, these materials are ideal for aerospace, electronics, and industrial applications. Our high-purity tungsten ensures exceptional durability and performance in even the most extreme conditions.