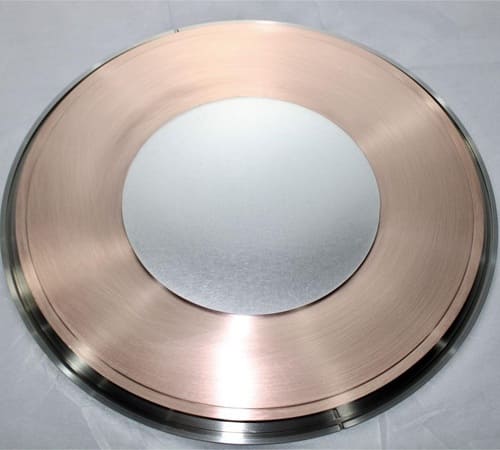

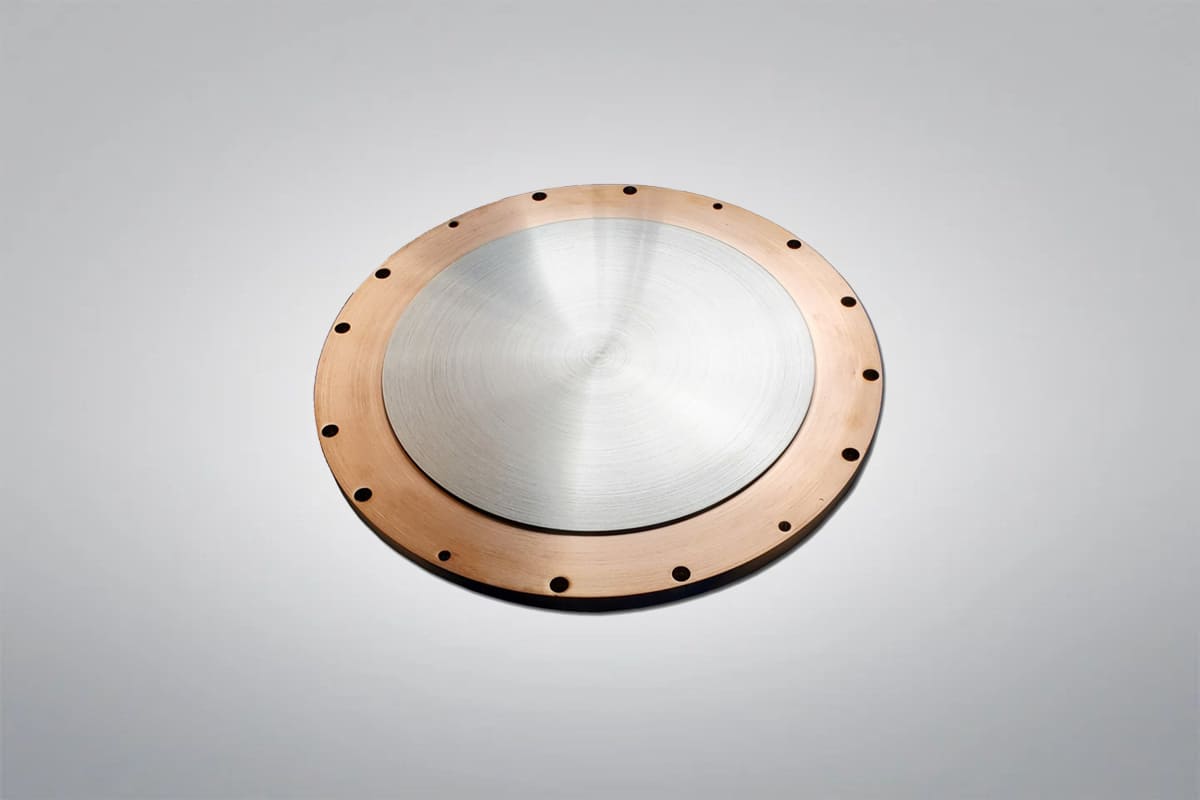

Platinum Sputtering Target

Platinum Sputtering Target

Purity: ≥99.95% or ≥99.99%

Shape: Disc, Rectangular, Tube, or customized

Platinum Sputtering Target is made from high-purity platinum with Pt≥99.95% or Pt≥99.99%, designing for thin film deposition in a variety of advanced applications including electronics, optics, solar energy, and coatings. As a leading supplier and manufacturer of premium platinum products, Heeger Metal leverages advanced technology to deliver high-quality platinum sputtering targets for various applications.

Or email us at sales@heegermaterials.com.Platinum Sputtering Target Data Sheet

| Reference Code: | HTST18 |

| Purity: | ≥99.95% or ≥99.99% |

| Melting Point: | 1722℃ |

| Boiling Point: | 3827℃ |

| Density: | 21.45 g/cm3 |

| Molecular Weight: | 195.078 g/mol |

| Shape: | Disc, Rectangular, Tube, or customized |

| Bonding: | Bonding or Unbonding |

Platinum Sputtering Target Description

Platinum (Pt) has excellent conductivity, corrosion resistance, and chemical stability, making it an ideal choice for sputtering processes that require precision and reliability. Platinum Sputtering Target is made from high-purity platinum with a purity of 99.95% or 99.99%. It is produced with strict quality control, ensuring high consistency, uniformity, and performance in every batch. Heeger Metal specializes in manufacturing high-quality platinum sputtering targets with customized specifications for multiple industrial and research applications, offering superior results in creating high-performance thin films.

Platinum Sputtering Target Chemical Composition

| Product | Platinum Sputtering Target | ||

| Pt (%) | 99.99 | 99.95 | |

| Impurities≤(%) | Pd | 0.003 | 0.01 |

| Rh | 0.003 | 0.02 | |

| Ir | 0.003 | 0.02 | |

| Ru | 0.003 | 0.02 | |

| Au | 0.003 | 0.01 | |

| Ag | 0.001 | 0.005 | |

| Cu | 0.001 | 0.005 | |

| Fe | 0.001 | 0.005 | |

| Ni | 0.001 | 0.005 | |

| Al | 0.003 | 0.005 | |

| Pb | 0.002 | 0.005 | |

| Mn | 0.002 | 0.005 | |

| Cr | 0.002 | 0.005 | |

| Mg | 0.002 | 0.005 | |

| Sn | 0.002 | 0.005 | |

| Si | 0.003 | 0.005 | |

| Zn | 0.002 | 0.005 | |

| Bi | 0.002 | 0.005 | |

| Total impurities ≤(%) | 0.01 | 0.05 | |

Platinum Sputtering Target Specifications

| Symbol | Pt |

| CAS | 7440-06-4 |

| Purity | 99.99% |

| Atomic Weight | 195.084 |

| Atomic Number | 78 |

| Color/Appearance | Metallic Grey |

| Thermal Conductivity | 72 W/m·K |

| Melting Point (℃) | 1772 |

| Coefficient of Thermal Expansion | 8.8×10-6/K |

| Theoretical Density (g/cc) | 21.45 |

| Z Ratio | 0.245 |

| Sputter | DC |

| Max Power Density (Watts/Square Inch) | 100* |

| Type of Bond | Indium, Elastomer |

Platinum Sputtering Target Stock Dimensions

| Circular Sputtering Targets | Diameter | 1.0″ 2.0″ 3.0″ 4.0″ 5.0″ 6.0″ up to 21″ |

| Rectangular Sputtering Targets | Width x Length | 5″ x 12″ 5””x 15″ 5″ x 20″ 5″ x 22″ 6″ x 20″ |

| Thickness | 0.125″, 0.25″ | |

Platinum Sputtering Target Manufacturing Processes

- Material Preparation: Select high-purity platinum raw material (typically ≥99.95% purity)

- Vacuum Induction Melting: A high-precision melting process using vacuum induction to ensure uniform alloy composition and eliminate contaminants.

- Annealing: A heat treatment process to relieve internal stresses, improve material properties, and achieve desired hardness and ductility.

- Rolling: The material is passed through rollers to reduce thickness, increase length, and refine the structure for further processing.

- Stamping: Using mechanical presses to shape or cut the material into specific forms, ensuring precise dimensions and consistency.

- Metallographic Testing: Detailed analysis of the material’s microstructure to ensure the quality and integrity of the alloy before further processing.

- Machining: Precision machining processes (such as turning, milling, or grinding) to achieve the desired shapes and tolerances.

- Dimensional inspection: Measuring and verifying the dimensions of the product to ensure they meet the required specifications.

- Cleaning: Thorough cleaning of the material to remove any residue, oils, or contaminants left from the manufacturing processes.

- Final Inspection: A comprehensive inspection process to ensure the product meets all quality and functional standards.

Platinum Sputtering Target Applications

- Semiconductor Industry: Used in sputtering to create high-performance thin films, such as electrodes, conductive layers, or barrier layers.

- Optical Coatings: Employed to produce highly reflective or corrosion-resistant optical films, such as mirrors or laser components.

- Medical Devices: Utilized for biocompatible coatings on implantable medical devices.

- Electronics Industry: Applied in producing sensors, resistors, or high-precision conductive films in integrated circuits.

- Scientific Research: Used in materials science to prepare specialized platinum-based thin films.

- Energy Sector: Employed in making electrode coatings for fuel cells or solar cells.

Platinum Sputtering Target Packaging

Platinum Sputtering Target is carefully placed in wooden cases or cartons with additional soft materials to support and prevent shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Platinum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Sputtering Targets Products

Heeger Metal offers a wide selection of high-performance sputtering targets made from materials like titanium, copper, aluminum, and rare earth metals. Our custom sputtering targets are precision-engineered to meet the demands of industries such as semiconductor manufacturing, photovoltaics, and electronics. With superior purity and consistency, our sputtering targets deliver exceptional film deposition performance, making them ideal for thin-film coating, sputtering, and PVD (Physical Vapor Deposition) applications.