Hafnium Powder

Hafnium Powder

Material: Hf+Zr≥99.95%, Zr≤2.5%

Purity: 99%-99.95%

Hafnium Powder is made from high-purity hafnium metal, with a wide range of purity and particle sizes. It is widely applied in aerospace, nuclear energy, and electronics. As a leading supplier and manufacturer of premium hafnium products, Heeger Materials leverages advanced technology to deliver high-purity hafnium and hafium alloys powders for wide ranges of applications.

Or email us at sales@heegermaterials.com.This product is currently unavailable. Please check other products. Thank you.

Hafnium Powder Data Sheet

| Reference: | HMHF1507 |

| Material: | Hf+Zr≥99.95%, Zr≤2.5% |

| CAS: | 7440-58-6 |

| Purity: | 99%-99.95% |

| Particle Size: | -60 mesh, -100 mesh, -200 mesh, -400 mesh, or customized |

| Density: | 13.31 g/cm3 |

| Melting Point: | 2230 ℃ |

| Boiling Point: | 4602 ℃ |

Hafnium Powder

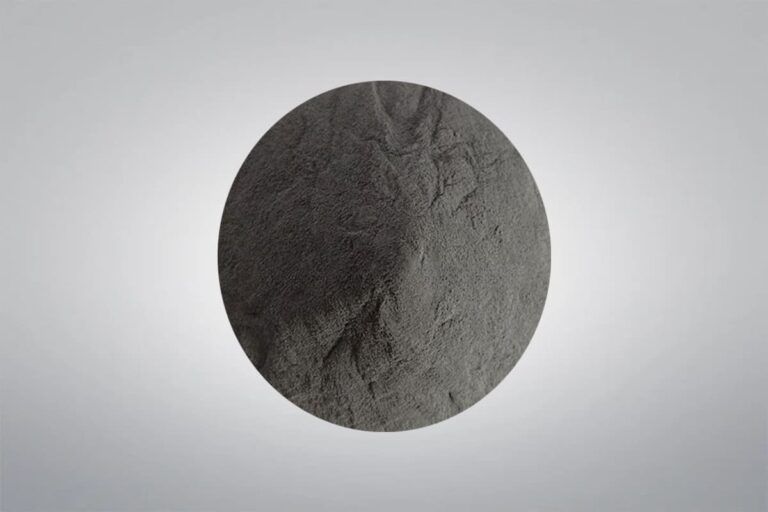

Hafnium (Hf) is a lustrous, silver-gray transition metal with a very high melting point (2230°C) and high density (13.31 g/cm3). Hafnium Powder is a grey-black powder, made of high-purity hafnium metal or its alloy. Irregular and spherical powders are available to suit various applications. HM can supply high-quality hafnium and hafnium alloy powders with customized purity and particle size solutions for multiple applications.

Hafnium Powder Specifications

| Chemical Composition (%) | |||||||||

| Hf+Zr | Zr | Si | Mo | Al | Ni | C | H | O | N |

| ≥99.95 | ≤1 | ≤0.001 | ≤0.001 | ≤0.0005 | ≤0.005 | ≤0.003 | ≤0.001 | ≤0.015 | ≤0.003 |

| Cu | Sn | Fe | Ti | Mn | Cr | Sb | Pb | Mg | Nb |

| ≤0.0005 | ≤0.0005 | ≤0.01 | ≤0.001 | ≤0.0005 | ≤0.001 | ≤0.0005 | ≤0.0005 | ≤0.0005 | ≤0.0005 |

| Particle Size | |||||||||

| -60 mesh, -100 mesh, -200 mesh, -400 mesh, or customized | |||||||||

Hafnium Powder Applications

- Nuclear Industry: Hafnium powder is used in nuclear reactors to make fuel casing materials and control rods.

- Alloy Manufacturing: Hafnium powder can manufacture high-temperature and high-strength alloys to enhance the alloy’s high-temperature resistance, oxidation resistance, and corrosion resistance.

- Electronic Components: Hafnium powders produce thin film coatings in electronic components.

- Spraying and Coating: Hafnium powders can be used for high-temperature spraying and as a coating material to improve the oxidation and wear resistance of metal surfaces.

- Catalysts and Chemical Reactions: Hafnium powders are used as catalysts or catalyst carriers in petrochemical and other chemical reaction processes.

Hafnium Powder Packaging

The Hafnium Powder is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Hafnium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Powder Products

Heeger Metal offers a comprehensive range of metal powder products, including spherical powders, and nano powders. Our high-quality metal powders are ideal for applications in 3D printing, powder metallurgy, electronics, and advanced manufacturing. These powders provide excellent consistency, flowability, and particle size distribution, ensuring superior performance in various industrial processes. Whether you need custom metal powders or standard alloy powders, our products meet the highest quality standards for precision and reliability.

Other Zirconium/Hafnium Products

Heeger Metal provides a wide selection of zirconium and hafnium products, celebrated for their excellent corrosion resistance, high temperature stability, and remarkable strength in extreme environments. These qualities make them ideal for critical applications in industries such as aerospace, nuclear power, and chemical processing. Our high-purity zirconium and hafnium materials ensure superior performance and durability, even in the most demanding conditions.