Molybdenum Foam

Molybdenum Foam

Purity: 99.95%-99.99%

Material: Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML)

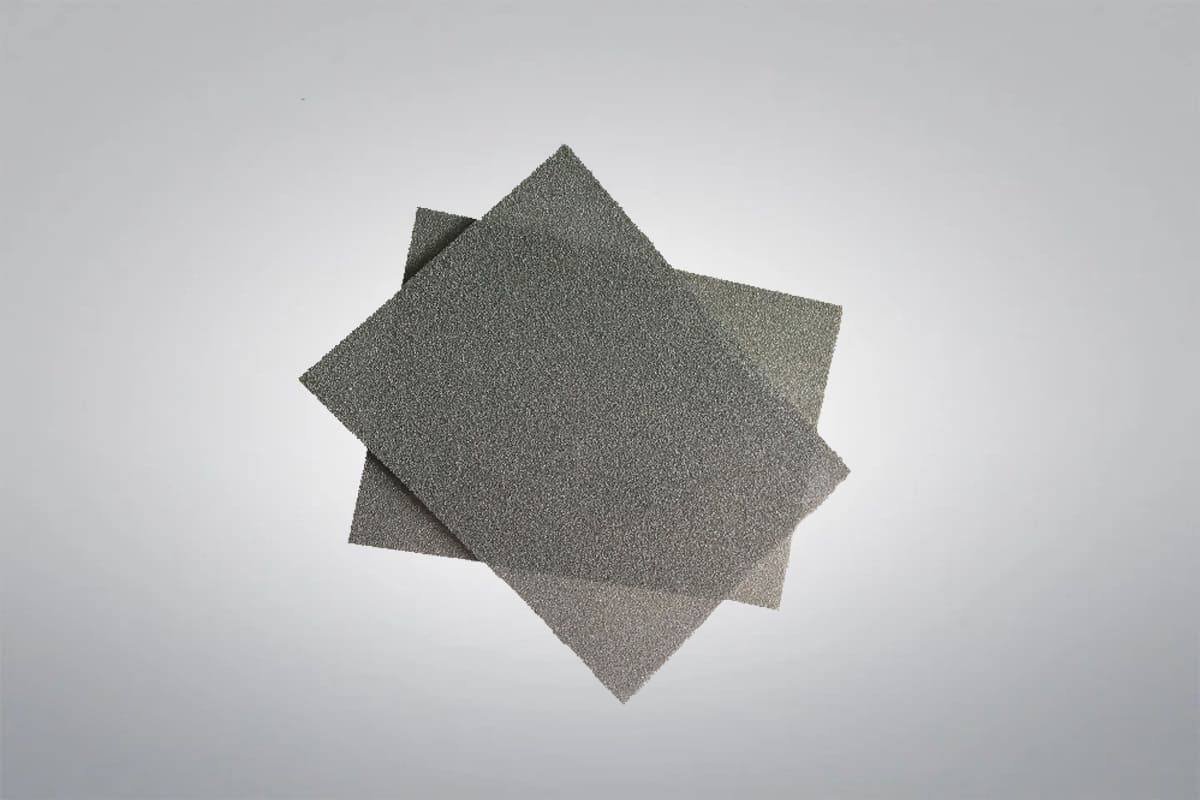

Molybdenum Foam is a porous metal material made of high-purity molybdenum, exhibiting low density and high strength. As a leading supplier and manufacturer of premium molybdenum products, Heeger Materials leverages advanced machining centers to deliver high-precision molybdenum and molybdenum alloy foam for wide ranges of applications.

Or email us at max@heegermaterials.com.Molybdenum Foam Data Sheet

| Reference: | HMMO1352 |

| Material: | Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML) |

| Purity: | 99.95%-99.99% |

| Shape: | Disc, Sheet, Tube, or Customized |

Molybdenum Foam

Molybdenum Foam is made of high-purity molybdenum or molybdenum alloy material, possessing a high porosity structure and a large specific surface area. It is widely applied in filter and catalyst carrier areas. It is also commonly used as battery electrode material. HM can supply customized solutions according to specific requirements at competitive prices.

Molybdenum Foam Material Chemical Composition

| Material | Mo | Impurities, (≤%) | |||||||||

| Al | Ca | Fe | Mg | Ni | Si | C | N | O | La2O3 | ||

| Mo1 | Bal. | 0.002 | 0.002 | 0.010 | 0.002 | 0.005 | 0.01 | 0.01 | 0.003 | 0.008 | – |

| Mo2 | Bal. | 0.005 | 0.004 | 0.015 | 0.005 | 0.005 | 0.01 | 0.02 | 0.003 | 0.020 | – |

| MoLa | Bal. | 0.002 | 0.002 | 0.015 | 0.005 | 0.005 | 0.01 | 0.02 | 0.005 | – | 0.1~1.8 |

| Note: The O content of MoLa alloy can be tested according to customer requirements. | |||||||||||

Molybdenum Foam Features

- High-temperature stability

- Electrical and thermal conductivity

- Good corrosion resistance

- High porosity

- Low density

- Large specific surface area

Molybdenum Foam Applications

- Catalyst Carriers: Molybdenum foam has a high specific surface area and good electrical conductivity, making it an ideal catalyst carrier, especially at high temperatures and in corrosive environments.

- Filtration Materials: Molybdenum foam can be used for efficient filtration and is suitable for filtration systems for gases and liquids.

- Battery Electrode Materials: Molybdenum foam is also used in battery electrode materials.

- Thermal Management Materials: The high thermal conductivity of molybdenum foam makes it suitable for thermal management applications such as heat sinks and heat exchangers.

- Acoustic Materials: Molybdenum foam is also used in acoustic materials.

Molybdenum Foam Packaging

The Molybdenum Foam is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Metal Foam Products

Heeger Metal offers a variety of custom metal foams and metal alloy foams, including tungsten foam, aluminum foam, and copper foam. These metal foams provide lightweight, high-strength, and excellent thermal conductivity, perfect for aerospace, automotive, and energy applications. Our porous metal foams and custom alloy foams meet the highest performance standards.

Other Molybdenum Products

We offer a wide range of molybdenum and molybdenum alloy products, from powders to finished parts, with customization options available. Please refer to the list for our common products.