Molybdenum Lanthanum Alloy

Molybdenum Lanthanum Alloy

Material: Mo-0.3%La2O3, Mo-0.6%La2O3, Mo-1.1%La2O3

Standard: ASTM B387 & ASTM B386

Molybdenum Lanthanum Alloy, also known as high-temperature molybdenum, consists of molybdenum doped with a small amount of lanthanum oxide (La2O3). It has excellent high-temperature mechanical properties. As a leading supplier and manufacturer of premium molybdenum products, Heeger Materials leverages advanced technology to deliver high-precision molybdenum lanthanum alloy products for wide ranges of applications.

Or email us at max@heegermaterials.com.Molybdenum Lanthanum Alloy Data Sheet

| Reference: | HMMO1085 |

| Material: | Mo-0.3%La2O3, Mo-0.6%La2O3, Mo-1.1%La2O3 |

| Purity: | 99.9%-99.99% |

| Standard: | ASTM B387 & ASTM B386 |

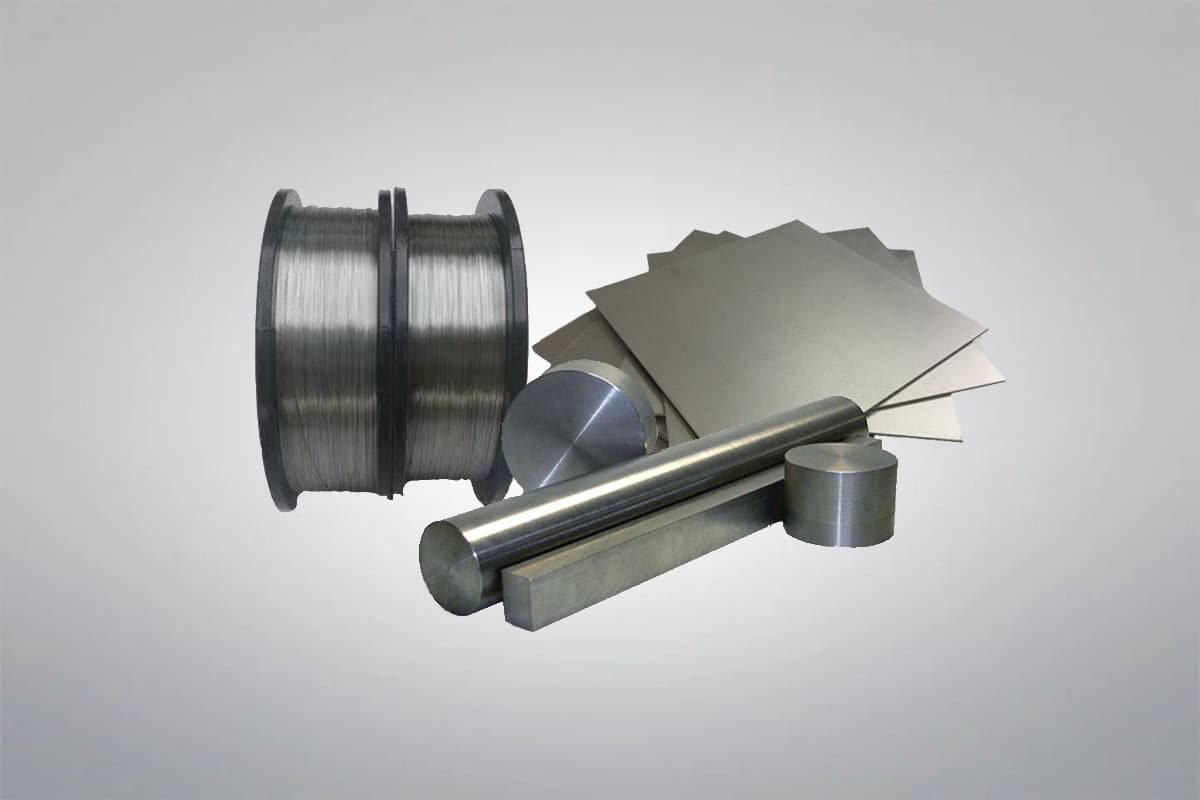

| Shape: | Plate, Sheet, Strip, Rod, Tube, Wire, Fastener, etc |

| Temper: | Annealed and Unannealed |

Molybdenum Lanthanum Alloy

Molybdenum Lanthanum Alloy consists of base molybdenum metal and trace lanthanum trioxide (La2O3), which is present in the matrix in the form of dispersed particles. The lanthanum oxide content of the alloy is typically 0.3%, 0.6%, and 1.1%. The addition of rare earth elements can not only improve the recrystallization temperature of molybdenum and high-temperature creep resistance but also significantly reduce the molybdenum plastic-brittle transition temperature, increasing the ductility. HM provides high-precision Mo-La alloy products in various forms, including rods, plates, sheets, tubes, wires, and custom parts, all crafted to ensure exceptional quality and customer satisfaction.

Molybdenum Lanthanum Alloy Plate Molybdenum Lanthanum Alloy Rod Molybdenum Lanthanum Alloy Tube Molybdenum Lanthanum Alloy Wire

Molybdenum Lanthanum Alloy Plate Specifications

| Item | Size | Process | Surface |

| Mo-La Alloy Plate | Thickness: 0.5-50 mm Length: Customized Width: Customized | Forging, rolling | Chemically cleaning, Grinding |

Molybdenum Lanthanum Alloy Rod Specifications

| Item | Size | Process | Surface |

| Mo-La Alloy Rod | Diameter: Φ1.0-150 mm Length: Customized | Drawing, Swaging | Black oxide, Chemically cleaning, Grinding |

Molybdenum Lanthanum Alloy Tube Specifications

| Item | Size | Process | Surface |

| Mo-La Alloy Tube | Out Diameter: 20-508 mm Length: Customized | Sintering, Gun drilling | Finish turning, Grinding |

Molybdenum Lanthanum Alloy Wire Specifications

| Item | Size | Shape | Surface |

| Mo-La Alloy Wire | φ0.5-4.0 mm, the length can be customized | Straight wire, Rolled wire | Black oxide, Chemically cleaning |

Molybdenum Lanthanum Alloy Mechanical Properties

| Material | Room Temperature | 1000 ℃ | ||

| Tensile Strength (MPa) | Elongation(%) | Tensile Strength (MPa) | Elongation(%) | |

| Mo-La Alloy | 650 | 25 | 220 | 20 |

| Note | Mo-La Alloy Rod with 30 mm diameter | |||

Molybdenum Lanthanum Alloy Features

- Higher recrystallization temperature (1400-1500 °C)

- Higher ductility improved by elongated particle structure

- Stronger oxidation resistance

- Higher creep resistance

Molybdenum Lanthanum Alloy Machining Service

HM has advanced machining centers equipped with various high-precision processing equipment, enabling us to offer multiple machining services such as turning, milling, grinding, and drilling. Whether for large-scale production or customized small-batch orders, we guarantee high precision and performance to meet customer’s specific requirements. The following are methods we will use during processing:

- Isostatic Pressing

- Forging

- Extrusion

- Molding

- Injection Molding

- Rolling

- Electrical Discharge Machining (EDM)

- Milling

- Turning

Molybdenum Lanthanum Alloy Applications

- Electronics Industry: Due to its high-temperature stability and good electrical conductivity, molybdenum-lanthanum alloy can be used to manufacture tubes, transistors, and other electronic components.

- Aerospace Industry: Due to its high strength and high-temperature resistance, molybdenum-lanthanum alloy is commonly used to produce rocket nozzles, spacecraft components, etc.

- Mechanical Industry: Molybdenum-lanthanum alloy is often used to manufacture high-temperature furnace components, molds, and dies.

Molybdenum Lanthanum Alloy Packaging

The Molybdenum Lanthanum Alloy is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Molybdenum Products

We offer a wide range of molybdenum and molybdenum alloy products, from powders to finished parts, with customization options available. Please refer to the list for our common products.