Molybdenum Mesh

Molybdenum Mesh

Standard: ASTM B386, ASTM B387

Material: Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML)

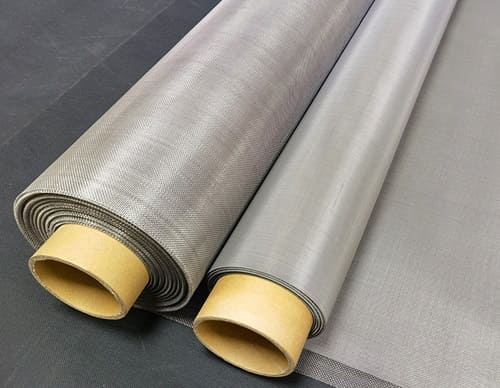

Molybdenum Mesh is made of high-purity molybdenum wire material, exhibiting high strength and low elogation. As a leading supplier and manufacturer of premium molybdenum products, Heeger Materials leverages advanced machining centers to deliver high-precision molybdenum and molybdenum alloy meshes for wide ranges of applications.

Or email us at max@heegermaterials.com.Molybdenum Mesh Data Sheet

| Reference: | HMMO1351 |

| Mesh: | 1-300 mesh, or customized |

| Weaving Type: | Plain Weave, Twill Weave, etc |

| Standard: | ASTM B386, ASTM B387 |

| Material: | Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML) |

| Purity: | 99.95%-99.99% |

| Surface: | Black Oxide, Chemically Cleaned |

| Temper: | Annealed or Unannealed |

Molybdenum Mesh

Molybdenum Mesh is made of high-purity molybdenum or molybdenum alloy wire, possessing similar properties to tungsten in many conditions. It has a series of excellent properties such as great strength at high temperatures, small vapor pressure, limited thermal expansion, outstanding heat conductivity, and low electric resistivity. It is commonly used in heating elements and high-temperature furnaces as structure support, mesh protectors, or filter media. HM can supply customized solutions according to specific requirements at competitive prices.

Molybdenum Mesh Material Chemical Composition

| Material | Mo | Impurities, (≤%) | |||||||||

| Al | Ca | Fe | Mg | Ni | Si | C | N | O | La2O3 | ||

| Mo1 | Bal. | 0.002 | 0.002 | 0.010 | 0.002 | 0.005 | 0.01 | 0.01 | 0.003 | 0.008 | – |

| Mo2 | Bal. | 0.005 | 0.004 | 0.015 | 0.005 | 0.005 | 0.01 | 0.02 | 0.003 | 0.020 | – |

| MoLa | Bal. | 0.002 | 0.002 | 0.015 | 0.005 | 0.005 | 0.01 | 0.02 | 0.005 | – | 0.1~1.8 |

| Note: The O content of MoLa alloy can be tested according to customer requirements. | |||||||||||

Molybdenum Mesh Specifications

| Mesh | Dia. Of Mesh (mm) | Aperture (mm) | Maximum Width (m) |

| 10 | 0.6 | 1.94 | 1.6 |

| 20 | 0.4 | 0.87 | 1.6 |

| 30 | 0.3 | 0.55 | 1.6 |

| 40 | 0.23 | 0.4 | 1.6 |

| 50 | 0.2 | 0.31 | 1.6 |

| 60 | 0.15 | 0.27 | 1.6 |

| 70 | 0.12 | 0.24 | 1.6 |

| 80 | 0.13 | 0.19 | 1.6 |

| 90 | 0.12 | 0.16 | 1.6 |

| 100 | 0.1 | 0.15 | 1.6 |

| 120 | 0.09 | 0.12 | 1.6 |

| 150 | 0.063 | 0.11 | 1.6 |

| 180 | 0.053 | 0.09 | 1.6 |

| 200 | 0.053 | 0.07 | 1.6 |

Molybdenum Mesh Advantages

- High tensile strength

- Low elongation

- Acid and alkaline resistance

- Corrosion resistance

- High-temperature resistance

- Good electricity-conductivity

- Lightweight

- Various hole shapes

- Excellent filtering performance

Molybdenum Mesh Applications

- High-Temperature Environment: Molybdenum mesh is commonly used in high-temperature furnaces and other high-temperature equipment.

- Petroleum and Chemical: Due to its acid- alkali-resistant and corrosion-resistant properties, molybdenum mesh is often used for filtration and screening in the petrochemical industry.

- Mechanical Manufacturing: Molybdenum mesh is used to manufacture certain specialized components due to its high strength and wear resistance.

- Food and Medicine: Due to its non-toxic and corrosion-resistant properties, molybdenum mesh is also used in the food and pharmaceutical industries.

- Aerospace: Molybdenum mesh is used as a key component in producing large deployable mesh parabolic antennas due to its high strength and electrical conductivity.

Molybdenum Mesh Packaging

The Molybdenum Mesh is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Mesh Products

Heeger Metal supplies a variety of metal mesh products and alloy mesh products. Our high-quality metal meshes are engineered for applications in industries like aerospace, electronics, filtration, and chemical processing, offering superior strength, corrosion resistance, and flexibility. Whether you need stamped meshes or woven metal mesh materials, our products deliver exceptional performance.

Other Molybdenum Products

We offer a wide range of molybdenum and molybdenum alloy products, from powders to finished parts, with customization options available. Please refer to the list for our common products.