Molybdenum Sputtering Target

Molybdenum Sputtering Target

Purity: 99.95%-99.99%

Material: Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML)

Molybdenum Sputtering Target is a thin film deposition material, made of high-purity molybdenum or molybdenum alloy. It exhibits high purity and density, widely allpied in semiconductors, chemical vapor deposition (CVD), physical vapor deposition (PVD), and optical areas. As a leading supplier and manufacturer of premium molybdenum products, Heeger Materials leverages advanced machining centers to deliver high-precision molybdenum and molybdenum alloy sputtering targets for wide ranges of applications.

Or email us at max@heegermaterials.com.Molybdenum Sputtering Target Data Sheet

| Reference: | HMST15 |

| Material: | Pure Mo361, MoTZM (Mo364), Mo-Lanthanoxid (ML) |

| Purity: | 99.95%-99.99% |

| Density: | 10.22 g/cm3 |

| Shape: | Flat, Rotary, or Customized |

| Bonding: | Unbonding or Bonding |

Molybdenum Sputtering Target

Molybdenum is a silver-grey metal with a melting point of 2623 ℃ and a density of 10.2 g/cm3. It is one of the commercially available metals with the lowest coefficient of thermal expansion. Molybdenum Sputtering Targets are made of high-purity molybdenum or molybdenum alloys, retaining the properties of the source materials. HM can supply high-quality molybdenum sputtering targets with advanced technology, ensuring high purity, high density, and small average grain size.

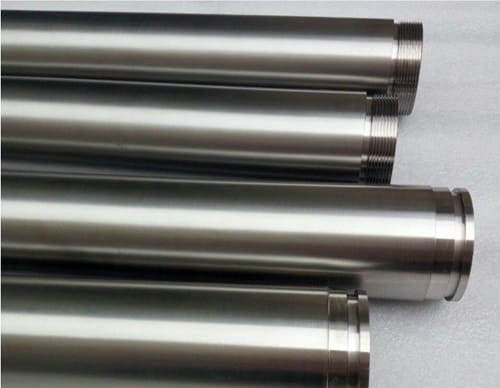

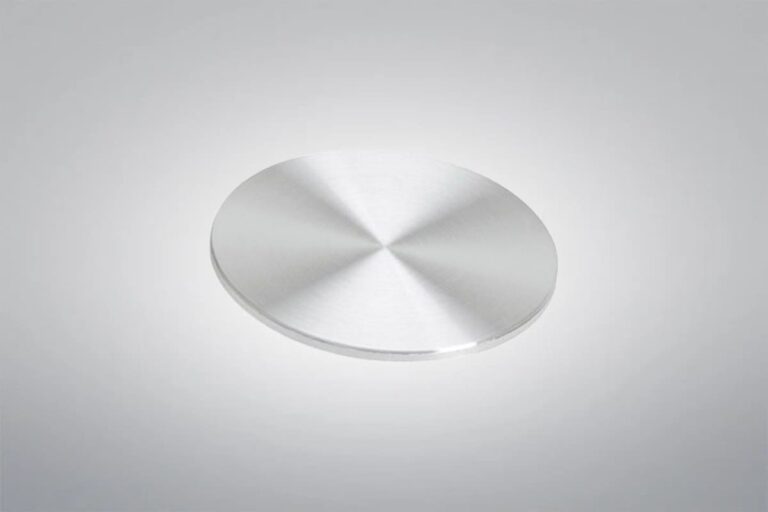

Circular Molybdenum Sputtering Target Rotary Molybdenum Sputtering Target Custom Molybdenum Sputtering Target

Molybdenum Sputtering Target Material Chemical Composition

| Material | Mo | Impurities, (≤%) | |||||||||

| Al | Ca | Fe | Mg | Ni | Si | C | N | O | La2O3 | ||

| Mo1 | Bal. | 0.002 | 0.002 | 0.010 | 0.002 | 0.005 | 0.01 | 0.01 | 0.003 | 0.008 | – |

| Mo2 | Bal. | 0.005 | 0.004 | 0.015 | 0.005 | 0.005 | 0.01 | 0.02 | 0.003 | 0.020 | – |

| MoLa | Bal. | 0.002 | 0.002 | 0.015 | 0.005 | 0.005 | 0.01 | 0.02 | 0.005 | – | 0.1~1.8 |

| Note: The O content of MoLa alloy can be tested according to customer requirements. | |||||||||||

Molybdenum Sputtering Target Specifications

| Material Type | Molybdenum | Coefficient of Thermal Expansion | 4.8 x 10-6/K |

| Symbol | Mo | Theoretical Density (g/cc) | 10.2 |

| Atomic Weight | 95.96 | Z Ratio | 0.257 |

| Atomic Number | 42 | Sputter | DC |

| Color/Appearance | Grey, Metallic | Max Power Density (Watts/Square Inch) | 150* |

| Thermal Conductivity | 139 W/m.K | Type of Bond | Indium, Elastomer |

| Melting Point (°C) | 2,617 | Comments | Films smooth, hard. |

Molybdenum Sputtering Target Stock Dimensions

| Circular Sputtering Targets | Diameter | 1.0″ 2.0″ 3.0″ 4.0″ 5.0″ 6.0″ up to 21″ |

| Rectangular Sputtering Targets | Width x Length | 5″ x 12″ 5””x 15″ 5″ x 20″ 5″ x 22″ 6″ x 20″ |

| Thickness | 0.125″, 0.25″ | |

Molybdenum Sputtering Target Production Process

Generally prepared using the powder metallurgy method, the purity of molybdenum powder should be above 99.95%. The specific process is as follows:

- Put the molybdenum powder in the vacuum heat treatment furnace for pre-gassing, then introduce hydrogen and continue heating for degassing.

- The degassed molybdenum powder is sintered once by vacuum hot pressing.

- The primary sintered product is passed through a hot isostatic press to complete the secondary sintering.

- After the secondary sintering, the whole surface of the product is ground by machining to get the final product.

Molybdenum Sputtering Target Features

- High Purity: Up to 99.99% purity

- High Density: Density close to the theoretical density of 10.22 g/cm3

- Uniform Microstructure: Ensuring uniform erosion during the sputtering process

- Small Average Grain Size: Ensuring the uniformity of the target

Molybdenum Sputtering Target Applications

- Semiconductor Manufacturing: Molybdenum sputtering targets are used to deposit conductive and shielding layers, especially in producing integrated circuits and microelectronic devices.

- Flat Panel Displays: Molybdenum sputtering targets are used to form electrodes and wiring materials in displays such as TFT-LCDs (thin-film transistor liquid crystal displays) and OLEDs (organic light-emitting diodes).

- Thin-Film Solar Cells: Molybdenum sputtering targets are used in the back-electrode layer of CIGS (copper indium gallium selenide) thin-film solar cells to improve the efficiency and stability of the cells.

- Medical Imaging Equipment: Molybdenum sputtering targets are used in X-ray tubes to generate high-quality X-rays and ensure the clarity and stability of imaging.

- Glass Coating: Molybdenum sputtering targets are used for coating glass surfaces to enhance the wear resistance and corrosion resistance of glass.

Molybdenum Sputtering Target Packaging

The Molybdenum Sputtering Target is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Sputtering Targets Products

Heeger Metal offers a wide selection of high-performance sputtering targets made from materials like titanium, copper, aluminum, and rare earth metals. Our custom sputtering targets are precision-engineered to meet the demands of industries such as semiconductor manufacturing, photovoltaics, and electronics. With superior purity and consistency, our sputtering targets deliver exceptional film deposition performance, making them ideal for thin-film coating, sputtering, and PVD (Physical Vapor Deposition) applications.

Other Molybdenum Products

We offer a wide range of molybdenum and molybdenum alloy products, from powders to finished parts, with customization options available. Please refer to the list for our common products.