Molybdenum Tungsten Alloy

Molybdenum Tungsten Alloy

Material: MoW70, MoW50

Reference: HMMO1349

Molybdenum Tungsten Alloy is a high-performance alloy material composed of molybdenum and tungsten, whose high-temperature strength, recrystallization temperature and corrosion resistance have been comprehensively improved. As a leading supplier and manufacturer of premium molybdenum products, Heeger Materials leverages advanced technology to deliver high-precision molybdenum tungsten alloy products for wide ranges of applications.

Or email us at max@heegermaterials.com.Molybdenum Tungsten Alloy Data Sheet

| Reference: | HMMO1349 |

| Material: | MoW70, MoW50 |

| Temper: | Annealed and Unannealed |

Molybdenum Tungsten Alloy

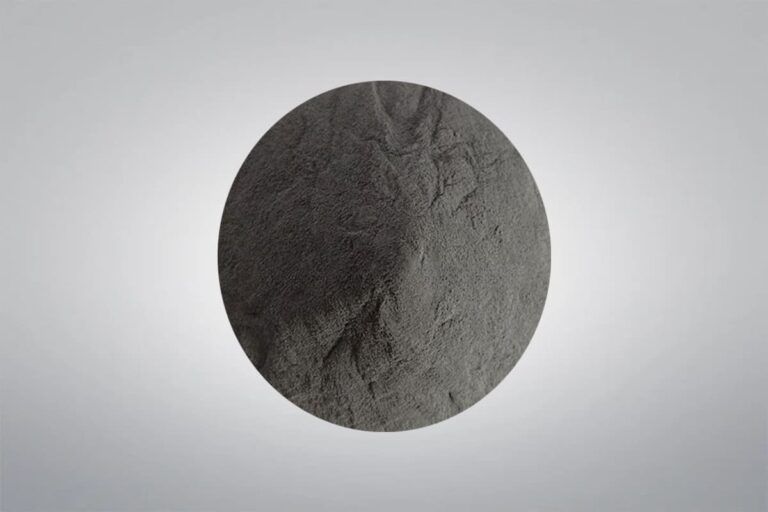

Molybdenum Tungsten Alloy is composed of molybdenum and tungsten and is obtained through powder metallurgy. HM provides high-precision molybdenum tungsten alloy products in various forms, including rods, plates, sheets, bars, tubes, blocks, pellets, wires, and discs, all crafted to ensure exceptional quality and customer satisfaction. We manufacture large, complex parts using isostatic pressure molding technology, while smaller parts are produced through extrusion, molding, and injection molding techniques. Additionally, rods and sheets are fabricated using forging and rolling processes.

Molybdenum Tungsten Alloy Rod Molybdenum Tungsten Alloy Block and Bar Molybdenum Tungsten Alloy Custom Parts

Molybdenum Tungsten Alloy Advantages

| MoW Alloy VS Pure Mo | MoW Alloy VS Pure W |

| 1. The recrystallization temperature of MoW is about 100°C higher. 2. Better corrosion resistance to molten zinc. 3. Higher strength | 1. Better molding performance 2. Lower density |

Molybdenum Tungsten Alloy Machining Service

HM has advanced machining centers equipped with various high-precision processing equipment, enabling us to offer multiple machining services such as turning, milling, grinding, and drilling. Whether for large-scale production or customized small-batch orders, we guarantee high precision and performance to meet customer’s specific requirements. The following are methods we will use during processing:

- Isostatic Pressing

- Forging

- Extrusion

- Molding

- Injection Molding

- Rolling

- Electrical Discharge Machining (EDM)

- Milling

- Turning

Molybdenum Tungsten Alloy Applications

- Zinc Smelting: Molybdenum-tungsten alloy has good resistance to zinc leaching, and is commonly used in zinc temperature measuring tubes, zinc pump rotors, and other parts used in the zinc processing industry.

- Glass Manufacturing: molybdenum-tungsten alloy can be used to manufacture stirrers.

- Electronics and Optics: Molybdenum-tungsten alloys are used as electrodes or structural parts in electron tubes and thyristors.

- High-temperature Components: Molybdenum-tungsten alloys are also commonly used to manufacture electrodes for high-temperature furnaces, flow ports, and thimble components.

Molybdenum Tungsten Alloy Packaging

The Molybdenum Tungsten Alloy is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Tungsten Products

Heeger Metal provides a wide range of tungsten and tungsten alloy products, from powders to finished components, with customization options available. Known for their outstanding strength, high melting point, and excellent wear and corrosion resistance, these materials are ideal for aerospace, electronics, and industrial applications. Our high-purity tungsten ensures exceptional durability and performance in even the most extreme conditions.

Other Molybdenum Products

We offer a wide range of molybdenum and molybdenum alloy products, from powders to finished parts, with customization options available. Please refer to the list for our common products.