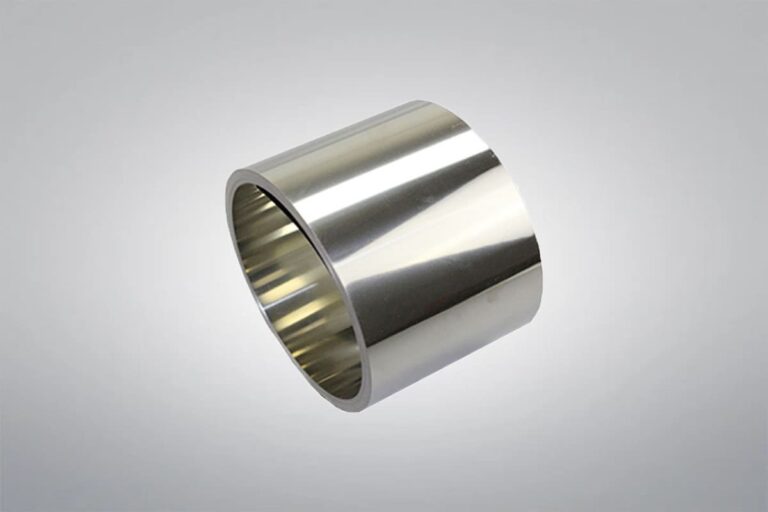

Titanium Crucible

Titanium Crucible

Material: Gr.1, Gr.2, Gr.3, Gr.7, Gr.9, Gr.12, Gr.16, etc.

Volume: 2 ml, 15 ml, 25 ml, 40 ml, 100 ml, or Customized

Titanium Crucible is made from high-purity titanium or titanium alloy, exhibiting excellent corrosion resistance, high strength, and lightweight. It is an ideal choice for melting and casting refractory metals. As a leading supplier and manufacturer of premium titanium products, Heeger Materials leverages advanced technology to deliver high-purity titanium and titanium alloy crucibles for a wide range of applications.

Or email us at sales@heegermaterials.com.Titanium Crucible Data Sheet

| Reference: | HMTT1004 |

| Material: | Gr.1, Gr.2, Gr.3, Gr.7, Gr.9, Gr.12, Gr.16, etc. |

| Volume: | 2 ml, 15 ml, 25 ml, 40 ml, 100 ml, or Customized |

| Shape: | Cylinder, Cone, Square, Rectangle, or Customized |

| Temper: | Annealed and Unannealed |

Titanium Crucible

Titanium (Ti), a silver transition metal with a low density of 4.54 g/cm3, exhibits lightweight, high strength, and corrosion resistance. Titanium Crucibles, made from high-quality titanium or titanium alloy, can withstand the melting process of metallic and non-metallic substances at high temperatures. The surface of titanium is easy to form a layer of dense oxide protective film, which provides resistance to strong acids and even aqua regia. HM can offer a wide range of shapes and specifications of high-precision titanium crucibles to meet your diverse needs.

Titanium Crucible Material Chemical Composition

| Type | Element (%) | ||||||||||

| N | C | H | Fe | O | Al | V | Mo | Ni | Pd | Ti | |

| GR.1 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.2 | ≤0.18 | Residual | |||||

| GR.2 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | Residual | |||||

| GR.3 | ≤0.05 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.35 | Residual | |||||

| GR.7 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | 0.12-0.25 | Residual | ||||

| GR.9 | ≤0.02 | ≤0.08 | ≤0.015 | ≤0.25 | ≤0.15 | 2.5-3.3 | 2.0-3.0 | Residual | |||

| GR.12 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | 0.2-0.4 | 0.6-0.9 | Residual | |||

| GR.16 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | 0.04-0.08 | |||||

Titanium Crucible Specifications

| Diameter (mm) | Wall Thickness (mm) | Height (mm) |

| 30 ~ 50 | 2 ~ 10 | 30 ~ 500 |

| 50 ~ 100 | 3 ~ 15 | |

| 100 ~ 150 | 3 ~ 15 | |

| 150 ~ 200 | 5 ~ 20 | |

| 200 ~ 300 | 8 ~ 20 | |

| 300 ~ 400 | 8 ~ 30 | |

| 400 ~ 450 | 8 ~ 30 | |

| 450 ~ 500 | 8 ~ 30 |

Titanium Crucible Production Process

- Raw Material: Select high-purity titanium powder.

- Powder Metallurgy: Mix with binder and compact into a green billet.

- Sintering: High-temperature sintering to remove the binder and increase density.

- Heat Treatment: Anneal to relieve stress and enhance properties.

- Surface Treatment: Clean and polish the surface.

Titanium Crucible Surface Finish

Depending on the intended applications, titanium crucibles have three main surface finishes as follows:

- Black: The surface is “as swaged” or “as drawn”, retaining a coating of processing lubricants and oxides.

- Cleaned: The surface is chemically cleaned to remove all lubricants and oxides.

- Ground: The surface is centerless to remove all coating and achieve precise dimensions control.

Titanium Crucible Safety Precautions For Use

- After use, store the titanium crucible in a dry place to prevent rainwater intrusion. Before use, gradually heat it to 500°C.

- Add materials according to the crucible’s capacity, avoiding overpacking to prevent cracking from the thermal expansion of the metal.

- When removing the metal solution, use a scoop rather than calipers. If calipers or other tools are necessary, ensure they match the shape of the crucible to prevent localized pressure that could shorten its lifespan.

- The crucible’s service life depends on usage. Avoid direct exposure to an oxidizing flame, as this can cause oxidation of the crucible material, leading to premature wear.

Titanium Crucible Applications

- Metal Casting and Melting: Titanium crucibles can maintain good stability at high temperatures, making them ideal for melting and casting refractory metals such as zirconium, tantalum, niobium, and their alloys.

- Chemical Experiments: Titanium crucibles can be used for melting, refining metal liquids, and conducting solid-liquid heating reactions, ensuring smooth processes.

- Electronic Industry: Titanium crucibles can be used for preparing electronic ceramics and magnetic materials, and in semiconductor processes such as diffusion and doping.

Titanium Crucible Packaging

The Titanium Crucible is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Titanium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Titanium Products

Heeger Metal offers a comprehensive range of titanium and titanium alloy products, including powders and finished parts, with customization options available. Renowned for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are perfect for aerospace, electronics, and chemical processing applications.

Other Crucible Products

Heeger Metal specializes in high-quality customized metal crucibles and alloy crucibles, designed to withstand extreme temperatures for melting and casting applications. Made from durable materials, our crucibles ensure excellent performance in industries such as metallurgy and material science. For more details or custom solutions, feel free to contact us.