TZM Molybdenum Alloy

TZM Molybdenum Alloy

Purity: 99.95%

Standard: ASTM B387 & ASTM B386

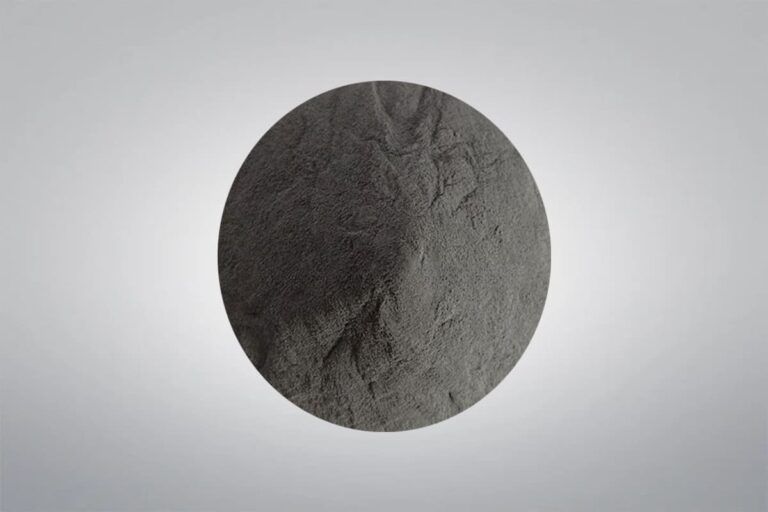

TZM Molybdenum Alloy is a high-temperature molybdenum-based alloy consisting of 0.5% titanium and 0.08% zirconium, exhibiting superior physical and chemical properties to those of pure molybdenum. As a leading supplier and manufacturer of premium molybdenum products, Heeger Materials leverages advanced technology to deliver high-precision TZM alloy products for wide ranges of applications.

Or email us at max@heegermaterials.com.TZM Molybdenum Alloy Data Sheet

| Reference: | HMMO1090 |

| Material: | Mo-0.5%Ti-0.08%Zr |

| Purity: | 99.95% |

| Density: | 10.2 g/cm3 |

| Melting Point: | 2620 ℃ |

| Standard: | ASTM B387 & ASTM B386 |

| Temper: | Annealed and Unannealed |

TZM Molybdenum Alloy

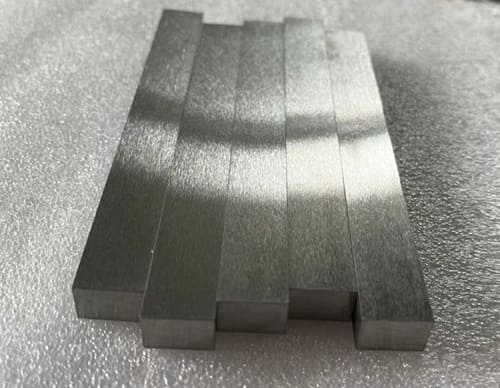

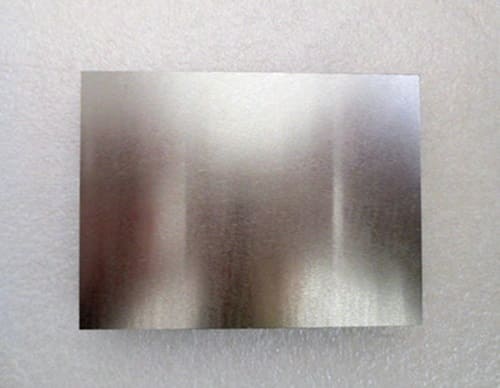

TZM Molybdenum Alloy is a high-temperature alloy material composed of molybdenum, titanium, and zirconium. The addition of trace titanium and zirconium significantly improves its resistance to deformation under extreme conditions. TZM alloys recrystallize at about 1400 ℃, much higher than molybdenum, providing better weldability. HM provides high-precision TZM alloy products in various forms, including rods, plates, sheets, bars, blocks, pellets, and discs, all crafted to ensure exceptional quality and customer satisfaction.

TZM Alloy Rod TZM Alloy Bar TZM Alloy Plate TZM Alloy Custom Part

Comparison of Physical Properties: TZM Alloy VS Molybdenum

| Material | Density (g/cm3) | Melting Point (℃) | Boiling Point (℃) |

| TZM Alloy | 10.22 | 2617 | 4612 |

| Mo | 10.29 | 2610 | 5560 |

TZM Alloy Mechanical Properties

| Mechanical Property | Elongation (%) | Modulus of Elasticity (GPa) | Yield Strength (MPa) | Tensile Strength (MPa) | Fracture Toughness (MP·m1/2) |

| Value | <20 | 320 | 560-1150 | 685 | 5.8-29.6 |

TZM Alloy High-Temperature Tensile Strength And Elongation

| Temperature (℃) | Properties | |

| Tensile Strength (MPa) | Elongation (%) | |

| RT | 1140-1210 | 7.5-13.0 |

| 1000 | 700-720 | 5.2 |

| 1200 | 320-360 | 9.0 |

| 1300 | 190-210 | 11.5-13.5 |

| 1400 | 140-170 | 11.0-16.0 |

TZM Alloy Thermal And Electrical Properties

| Properties | The Coefficient of Thermal Expansion (K-1) (20-100 ℃) | Thermal Conductivity (W/m·K) | Max operating temperature in air (℃) | Resistivity (Ω·m) |

| Value | 5.3×10-6 | 126 | 400 | (5.3-5.5)×10-8 |

TZM Molybdenum Alloy Products

| Product | Standard | Size | Process | Surface |

|---|---|---|---|---|

| TZM Alloy Wire | ASTM B387, TYPE 364 | 0.5-4.0mm diameter x L | – | Black oxide, chemically cleaned |

| TZM Alloy Rod | ASTM B387, TYPE 364 | 4.0-100mm diameter x <2000mm L | Drawing, swaging | Black oxide, chemically cleaned, Grinding |

| TZM Alloy Plate | ASTM B386, TYPE 364 | 4.75- 50mm thickness x W x L | Forging, rolling | Chemically cleaned, Grinding |

| TZM Alloy Tube | ASTM B387, TYPE 364 | 0.8″-20″ OD, 106″ max length per piece | Sintering, drilling | Black oxide, chemically cleaned, Grinding |

TZM Molybdenum Alloy Features

- Excellent corrosion resistance

- High-temperature resistance

- High melting point

- High strength

- High elastic modulus

- Small linear expansion coefficient

- Low vapor pressure

- Good electrical and thermal conductivity

- Strong corrosion resistance

- Good high-temperature mechanical properties

TZM Molybdenum Alloy Machining Service

HM has advanced machining centers equipped with various high-precision processing equipment, enabling us to offer multiple machining services such as turning, milling, grinding, and drilling. Whether for large-scale production or customized small-batch orders, we guarantee high precision and performance to meet customer’s specific requirements. The following are methods we will use during processing:

- Isostatic Pressing

- Forging

- Extrusion

- Molding

- Injection Molding

- Rolling

- Electrical Discharge Machining (EDM)

- Milling

- Turning

TZM Molybdenum Alloy Applications

- Defense industry: TZM Alloy can be used for manufacturing high-temperature warheads, missile engines, etc.

- Electronic industry: TZM Alloy can be used for electron tube cathode, gate, high-voltage rectifier components, semiconductor thin-film integrated circuits, etc.

- Nuclear energy equipment: TZM Alloy can be used for radiation shields, support frames, heat exchangers, rail strips, etc.

- High-temperature structural materials: TZM Alloy can be used for high-temperature furnace components.

- Medical equipment: TZM Alloy can be used for manufacturing medical equipment such as X-ray targets, pacemakers, etc.

TZM Molybdenum Alloy Packaging

The TZM Molybdenum Alloy is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Molybdenum Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Molybdenum Products

We offer a wide range of molybdenum and molybdenum alloy products, from powders to finished parts, with customization options available. Please refer to the list for our common products.