Titanium Foil/Strip/Ribbon

Titanium Foil/Strip/Ribbon

Material: Gr.1, Gr.2, Gr.3, Gr.7, Gr.9, Gr.12, Gr.16, etc.

Standard: ASTM B265, etc.

Titanium Foil/Strip/Ribbon is high-precision material made from high-purity titanium or titanium alloys with excellent corrosion resistance, high strength-to weight ratio and good biocompatibility. As a leading supplier and manufacturer of premium titanium products, Heeger Materials leverages advanced technology to deliver high-purity titanium and titanium alloy foils, strips, and ribbons for various applications.

Or email us at sales@heegermaterials.com.Titanium Foil/Strip/Ribbon Data Sheet

| Reference: | HMTT1007 |

| Material: | Gr.1, Gr.2, Gr.3, Gr.7, Gr.9, Gr.12, Gr.16, etc. |

| Standard: | ASTM B265, etc. |

| Specifications: | Thickness: 0.01-2.00 mm Width: 30-500 mm Length: TBD (To Be Determined) |

| Temper: | Annealed and Unannealed |

Titanium Foil/Strip/Ribbon

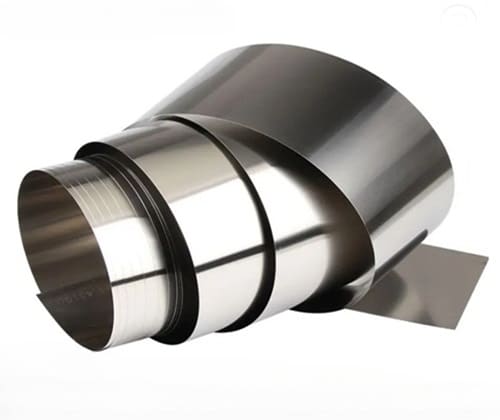

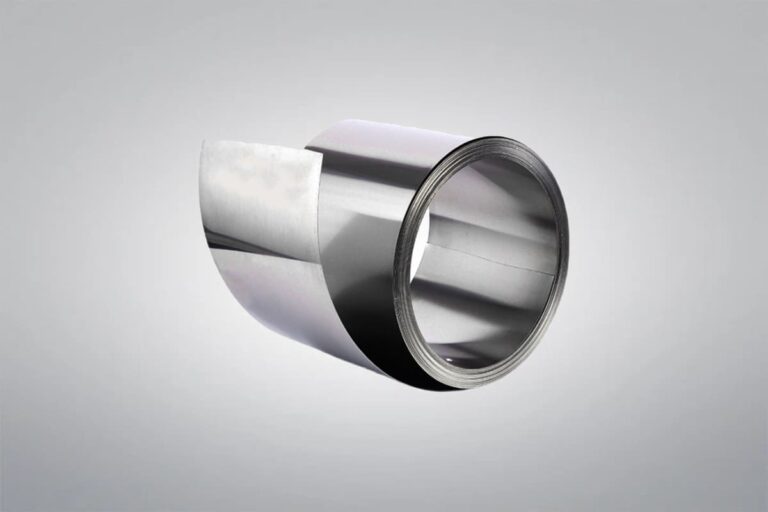

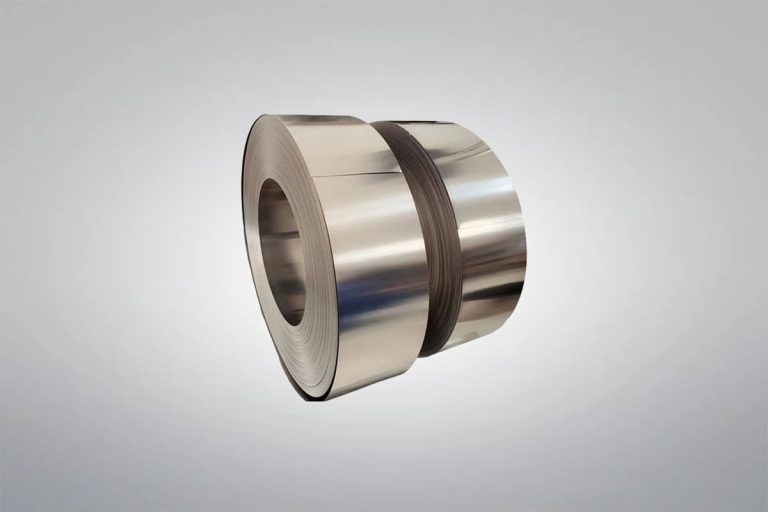

Titanium (Ti), a silver transition metal with a low density of 4.54 g/cm3, exhibits lightweight, high strength, and corrosion resistance. Titanium Foil/Strip/Ribbon is crafted from high-purity titanium or titanium alloys, suitable for aerospace, medical devices, chemicals, electronics, and new energy industries. Foil thickness is typically available in 0.01 to 0.1 mm, while strip and ribbon thicknesses generally range from 0.1 to 2.0 mm. HM uses the advanced rolling process to ensure high dimensional accuracy and excellent surface quality. We can offer high-precision titanium foil/strip/ribbon with various specifications and grades to meet multiple requirements.

Titanium Foil Titanium Foil Titanium Strip/Ribbon

Titanium Foil/Strip/Ribbon Material Chemical Composition

| Type | Element (%) | ||||||||||

| N | C | H | Fe | O | Al | V | Mo | Ni | Pd | Ti | |

| GR.1 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.2 | ≤0.18 | Residual | |||||

| GR.2 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | Residual | |||||

| GR.3 | ≤0.05 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.35 | Residual | |||||

| GR.7 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | 0.12-0.25 | Residual | ||||

| GR.9 | ≤0.02 | ≤0.08 | ≤0.015 | ≤0.25 | ≤0.15 | 2.5-3.3 | 2.0-3.0 | Residual | |||

| GR.12 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | 0.2-0.4 | 0.6-0.9 | Residual | |||

| GR.16 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.3 | ≤0.25 | 0.04-0.08 | |||||

Titanium Foil/Strip/Ribbon Specifications

| Material | Type | Dimensions | Temper | ||

| Thickness (mm) | Width (mm) | Length (mm) | |||

| Gr.1, Gr.2, Gr.7, Gr.12 | Foil | 0.01-0.02 | 30-100 | ≥500 | Annealed and Unannealed |

| 0.03-0.09 | 50-300 | ≥500 | |||

| Strip/Ribbon | 0.10-0.30 | 50-300 | ≥500 | ||

| 0.40-0.90 | 50-500 | ≥1000 | |||

| 1.0-2.0 | 50-500 | ≥2000 | |||

Titanium Foil/Strip/Ribbon Regular Dimensions & Tolerances

| Thickness (mm) | Thickness Tolerance (mm) | Width (mm) | Width Tolerance (mm) | Length (mm) | Length Tolerance (mm) | |

| General Precision | Higher Precision | |||||

| 0.01、0.02 | ±0.003 | ±0.002 | 30–100 | ±0.5 | ≥500 | +10 |

| 0.03、0.04、0.05 | ±0.005 | ±0.003 | 50–300 | |||

| 0.06、0.07 | ±0.007 | ±0.005 | ||||

| 0.08、0.09 | ±0.010 | ±0.007 | ||||

| 0.10、0.12、0.15 | ±0.015 | ±0.010 | ||||

| 0.18、0.20 | ±0.02 | ±0.015 | ||||

| 0.25、0.30 | ±0.03 | ±0.02 | ||||

| 0.40、0.50 | ±0.05 | ±0.04 | 50–500 | ±1.0 | ≥1000 | +15 |

| 0.60、0.70、0.80、0.90 | ±0.07 | ±0.05 | ||||

| 1.00 | ≥2000 | |||||

| 1.10、1.20、1.30、1.40、1.50 | ±0.09 | ±0.07 | ±1.5 | |||

| 1.60、1.70、1.80、1.90、2.0 | ±0.12 | ±0.10 | ±2.0 | |||

| Note: 1、 We can provide non-standard products with specifications tailored to customer requirements, with thickness tolerances following those of the next larger standard size. 2、For foil with a length ≥ 300mm in the annealed condition, the length tolerance is +10mm. | ||||||

Titanium Foil/Strip/Ribbon Applications

- Aerospace: Titanium foil/strip/ribbon is used to manufacture aircraft and spacecraft components because of its high strength and low density.

- Electronic Industry: Titanium foil/strip/ribbon is used as a conductive and shielding material in electronic equipment.

- Medical: Titanium foil/strip/ribbon is used to make surgical instruments, implants, and dental materials.

- Chemical Equipment: Titanium foil/strip/ribbon can be used as lining and sealing materials for chemical equipment.

- Energy: Titanium foil/strip/ribbon is used in solar panels and fuel cells.

Titanium Foil/Strip/Ribbon Packaging

The Titanium Foil/Strip/Ribbon is carefully placed in wooden cases or cartons with additional support from soft materials to prevent any shifting during transportation. This packaging method guarantees the integrity of the products throughout the delivery process.

Titanium Properties

Download

Get A Quote

We will check and get back to you in 24 hours.

Other Titanium Products

Heeger Metal offers a comprehensive range of titanium and titanium alloy products, including powders and finished parts, with customization options available. Renowned for their exceptional strength, corrosion resistance, and high-temperature stability, these materials are perfect for aerospace, electronics, and chemical processing applications.

Other Foil/Strip/Ribbon Products

Heeger Metal provides a wide range of metal foil, metal strip, and metal ribbon products. Our foil and strip materials are precision-engineered for applications requiring high strength, flexibility, and thermal stability, ideal for electronics, aerospace, and industrial sectors. Whether you need custom metal ribbons or thin metal strips, our products deliver superior performance and reliability.