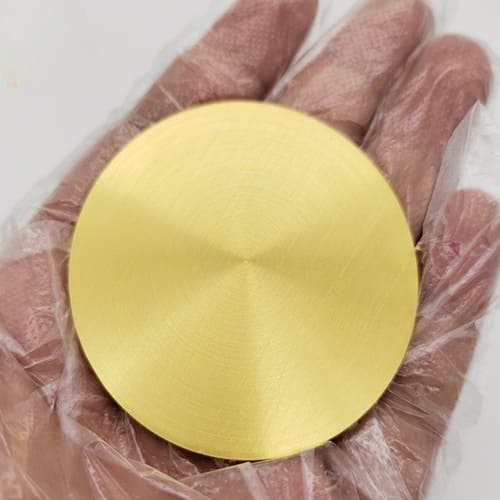

Blanco para sputtering de oro

Blanco para sputtering de oro

Pureza: ≥99,95%, o personalizada

El cátodo para sputtering de oro está fabricado con metal dorado de gran pureza mediante técnicas precisas y está diseñado para procesos de deposición de películas finas. Está disponible en varios tamaños y formas para adaptarse a diferentes sistemas de sputtering. Como proveedor y fabricante líder de productos de oro de primera calidad, Heeger Metal aprovecha la tecnología avanzada para suministrar cátodos para sputtering de oro de alta calidad para diversas aplicaciones.

O envíenos un correo electrónico a sales@heegermaterials.com.Hoja de datos de cátodos para sputtering de oro

| Código de referencia: | HTST288 |

| CAS: | 7440-57-5 |

| Pureza: | ≥99.95%, o personalizado |

| Densidad: | 19,283 g/cm3 |

| Punto de fusión: | 1064℃ |

| Punto de ebullición: | 2970℃ |

| Forma: | Disco, rectangular, tubo o personalizado |

| Boding: | Vinculación o desvinculación |

Descripción del cátodo para sputtering de oro

El oro (Au) tiene una excelente conductividad, estabilidad química y maleabilidad, lo que lo hace muy valioso para diversas aplicaciones. Blanco para sputtering de oro está fabricado con oro metálico de gran pureza, diseñado para procesos de deposición de película fina. Con su rendimiento estable y calidad constante, nuestros cátodos para sputtering de oro garantizan revestimientos lisos y uniformes para células solares, sensores e instrumentos de precisión. Heeger Metal puede suministrar cátodos para sputtering de oro de alta calidad en varias especificaciones y soluciones personalizadas para adaptarse a aplicaciones industriales y de investigación, garantizando un rendimiento óptimo y rentabilidad.

Especificaciones del cátodo para sputtering de oro

| Símbolo | Au |

| Peso atómico | 196.966569 |

| Número atómico | 79 |

| Color/Apariencia | Oro, Metálico |

| Conductividad térmica | 320 W/m.K |

| Punto de fusión (°C) | 1,064 |

| Coeficiente de dilatación térmica | 14,2 x 10-6/K |

| Densidad teórica (g/cc) | 19.32 |

| Ratio Z | 0.381 |

| Pulverización catódica | DC |

| Densidad de potencia máxima (vatios/pulgada cuadrada) | 100* |

| Tipo de bono | Indio, elastómero |

| Comentarios | Películas blandas; poco adherentes. |

Dimensiones de los cátodos para sputtering de oro

| Cátodos para sputtering circular | Diámetro | 1.0″ 2.0″ 3.0″ 4.0″ 5.0″ 6.0″ hasta 21″. |

| Cátodos rectangulares para sputtering | Anchura x Longitud | 5″ x 12″ 5""x 15″ 5″ x 20″ 5″ x 22″ 6″ x 20″ |

| Espesor | 0.125″, 0.25″ | |

Aplicaciones de cátodos para sputtering de oro

- Industria de semiconductores: Los cátodos para sputtering de oro se utilizan para producir componentes microelectrónicos, incluidos circuitos integrados, sensores y conectores, proporcionando una excelente conductividad y fiabilidad.

- Revestimientos de película fina: Comúnmente utilizado en la producción de películas finas de oro para revestimientos ópticos, mejorando la reflectividad y la durabilidad.

- Células solares: La pulverización catódica de oro se emplea en la fabricación de células solares de película fina para mejorar la eficiencia y el rendimiento.

- Dispositivos ópticos: Se utiliza para crear revestimientos reflectantes para lentes ópticas, espejos y otros dispositivos, garantizando una transmisión y reflexión de la luz de alta calidad.

- Aplicaciones biomédicas: Los cátodos para sputtering de oro se utilizan en la fabricación de revestimientos biocompatibles para dispositivos médicos, como implantes y sensores, debido a su biocompatibilidad e irreactividad.

- Tecnología de visualización: Las películas finas de oro se utilizan en la fabricación de tecnologías avanzadas de visualización, incluidas las pantallas planas y táctiles.

- Sensores: Los recubrimientos de oro se aplican a los sensores por sus excelentes propiedades conductoras, que garantizan una alta sensibilidad y precisión en aplicaciones como sensores de gas, biosensores y sensores químicos.

Embalaje de cátodos para sputtering de oro

Los cátodos para sputtering de oro se colocan cuidadosamente en cajas de madera o cartón con materiales blandos adicionales para sujetarlos y evitar que se desplacen durante el transporte. Este método de embalaje garantiza la integridad de los productos durante todo el proceso de entrega.

Propiedades de oro

Descargar

Solicitar presupuesto

Lo comprobaremos y le responderemos en 24 horas.

Cátodos para sputtering Productos

Heeger Metal ofrece una amplia selección de cátodos para sputtering de alto rendimiento fabricados con materiales como titanio, cobre, aluminio y metales de tierras raras. Nuestros cátodos para sputtering personalizados están diseñados con precisión para satisfacer las demandas de industrias como la fabricación de semiconductores, la fotovoltaica y la electrónica. Con una pureza y consistencia superiores, nuestros cátodos para sputtering ofrecen un rendimiento excepcional en la deposición de películas, lo que los hace ideales para aplicaciones de recubrimiento de películas finas, sputtering y PVD (deposición física de vapor).