Placa/hoja/disco de plata

Placa/hoja/disco de plata

Pureza: ≥99,95%, o personalizada

La placa/hoja/disco de plata se fabrica con metal de plata de gran pureza mediante técnicas precisas. Ofrece una excelente conductividad eléctrica, resistencia a la corrosión y conductividad térmica, y está disponible en varios tamaños y grosores. Como proveedor y fabricante líder de productos de plata de primera calidad, Heeger Metal aprovecha la tecnología avanzada para ofrecer placas, láminas y discos de plata de alta calidad para diversas aplicaciones.

O envíenos un correo electrónico a max@heegermaterials.com.Placa/hoja/disco de plata Hoja de datos

| Código de referencia: | HMSI2713 |

| CAS: | 7440-22-4 |

| Pureza: | ≥99.95%, o personalizado |

| Densidad: | 10,503 g/cm3 |

| Punto de fusión: | 961.78℃ |

| Punto de ebullición: | 2162℃ |

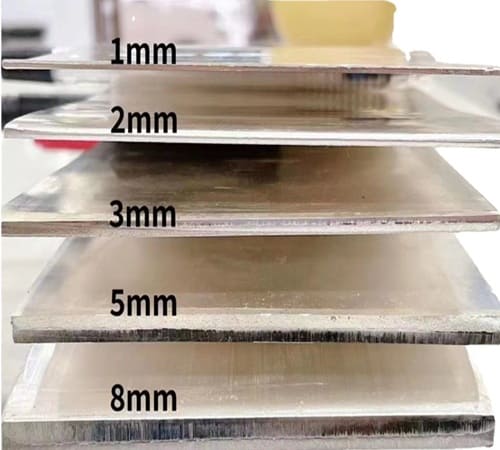

| Grosor: | 0,1-10 mm, o personalizado |

| Estado de entrega: | Estados duro, semiduro o blando según los requisitos específicos |

| Temperamento: | Recocido o sin recocido |

Placa/hoja/disco de plata Descripción

La plata (Ag) es un metal precioso conocido por su mayor conductividad eléctrica, conductividad térmica y reflectividad que cualquier otro metal. Además, tiene una excelente resistencia a la corrosión y la oxidación. La placa/hoja/disco de plata está hecha de metal de plata de gran pureza, ampliamente aplicado en electrónica, componentes eléctricos y paneles solares. Heeger Metal puede suministrar placas, láminas y discos de plata de alta calidad en varias especificaciones y soluciones personalizadas para adaptarse a aplicaciones industriales y de investigación, garantizando un rendimiento óptimo y rentabilidad.

Procesos de fabricación de placas, láminas y discos de plata

- Fundición: A continuación, la plata refinada se funde en un horno a altas temperaturas, normalmente en torno a los 960 °C (1760 °F). Esto permite que la plata alcance un estado líquido.

- Fundición: Una vez fundida, la plata líquida se vierte en moldes para formar barras o tochos. Estos tochos son el material de partida para producir planchas, láminas o discos de plata.

- Rodando: Los tochos de plata se calientan y pasan por trenes de laminación, donde se reduce gradualmente su grosor y se les da forma de chapas finas o placas. El proceso de laminado se realiza por etapas, cada una de las cuales reduce el grosor de forma incremental.

- Recocido: Para evitar que la plata se vuelva quebradiza debido al endurecimiento por deformación durante el proceso de laminado, la plata se calienta periódicamente en un horno de recocido. Esto ablanda el metal y le devuelve su ductilidad.

- Corte y conformado: Una vez que la placa o lámina de plata alcanza el grosor deseado, puede cortarse en discos u otras formas utilizando herramientas de corte especializadas. Los discos suelen troquelarse o perforarse a partir de láminas más grandes.

- Pulido y tratamiento de superficies: Después de dar forma a la placa, lámina o disco de plata, se pule para conseguir una superficie lisa y brillante. Esto puede hacerse utilizando materiales abrasivos o mediante técnicas de electropulido.

- Control de calidad: Los productos finales se someten a rigurosos controles de calidad para detectar defectos, como imperfecciones de grosor, calidad de la superficie y aspecto general. También se comprueba su pureza para garantizar que cumplen las normas del sector.

Aplicaciones de placa/hoja/disco de plata

- Electrónica: Las placas, láminas y discos de plata se utilizan ampliamente en la producción de contactos eléctricos, conectores y conductores debido a su excelente conductividad eléctrica.

- Revestimientos reflectantes: La alta reflectividad de la plata la hace ideal para su uso en espejos ópticos y revestimientos reflectantes para instrumentos como telescopios y láseres.

- Paneles solares: La plata es un material clave en las células fotovoltaicas, y las placas o láminas de plata se utilizan en la fabricación de paneles solares para una conversión eficiente de la energía.

- Aplicaciones médicas: Debido a su biocompatibilidad, la plata se utiliza en productos sanitarios, como implantes, apósitos para heridas y revestimientos de instrumentos quirúrgicos para evitar el crecimiento bacteriano.

- Conductividad térmica: Las placas y láminas de plata se utilizan en aplicaciones que requieren una alta conductividad térmica, como intercambiadores de calor y sistemas de refrigeración en electrónica y procesos industriales.

Envasado en plato/hoja/disco de plata

Silver Plate/Sheet/Disc se colocan cuidadosamente en cajas de madera o cartón con materiales blandos adicionales para sujetarlos y evitar que se desplacen durante el transporte. Este método de embalaje garantiza la integridad de los productos durante todo el proceso de entrega.

Propiedades de plata

Descargar

Solicitar presupuesto

Lo comprobaremos y le responderemos en 24 horas.

Otros productos de placa/hoja/disco

Heeger Metal ofrece una amplia gama de placas, chapas y discos a medida, disponibles en materiales como tungsteno, molibdeno, titanio y aleaciones de níquel. Nuestros productos de ingeniería de precisión son ideales para diversas aplicaciones industriales, como la aeroespacial, la electrónica y la energía. Tanto si necesita placas planas, chapas finas o discos cortados con precisión, le ofrecemos soluciones a medida con una resistencia, durabilidad y características de alto rendimiento excepcionales para satisfacer sus requisitos específicos.